Featured Stories

Understanding Solids, Surfaces, and Meshes in Mastercam

In CNC programming, the model you start with shapes everything that follows — from toolpath precision to workflow efficiency. Mastercam provides programmers three primary model types to work with: solids, surfaces, and meshes. Let's break down the differences.

Mastercam 2026.R2: Enhanced 3Dconnexion Integration for Smoother 3D Navigation

In Mastercam 2026.R2, we have significantly upgraded our 3Dconnexion device integration through a complete rebuild of our Navlib API implementation. Here is a quick look at how this update changes the way you work.

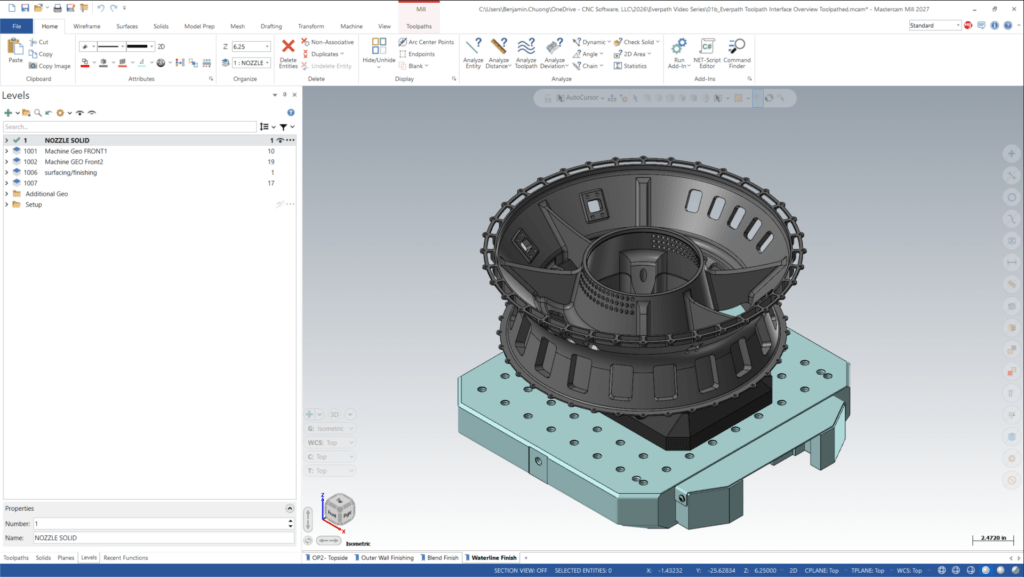

Mastercam EverPath Technology: Early Adopter Program

As part of our ongoing commitment to innovation and customer feedback, we are launching the Early Adopter Program, an insider track for latest development updates and opportunity to share feedback directly with our development team. Are you ready to join?

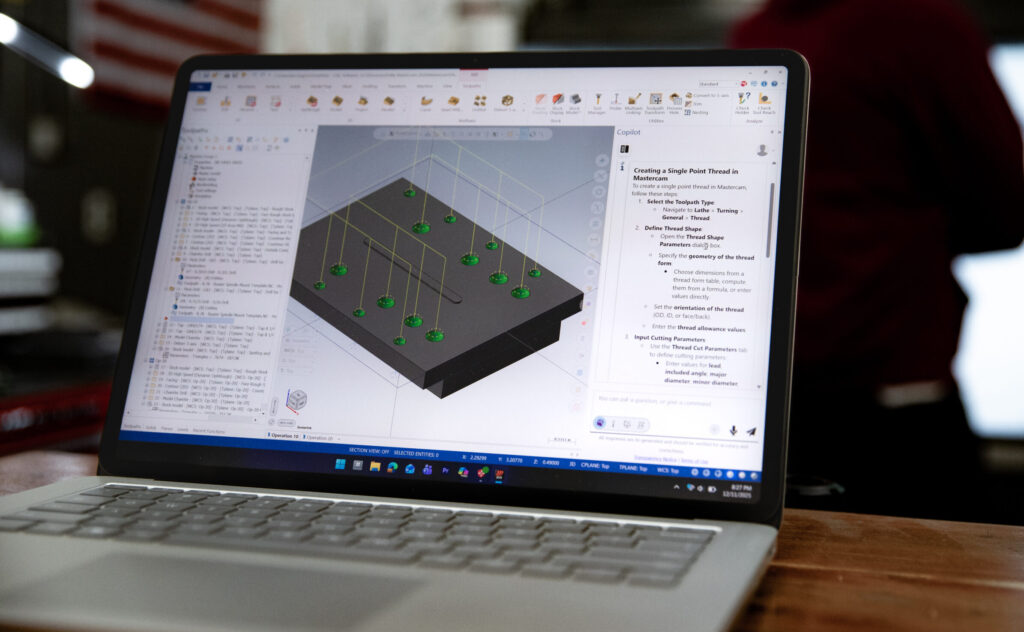

Mastercam Copilot in 2026.R2: Faster Commands, Smarter Automation, and Hands-Free Programming

With new AI-powered capabilities, expanded voice control, and deeper integration with learning resources, Mastercam Copilot has evolved into a powerful assistant that helps you work faster, smarter, and with greater confidence.

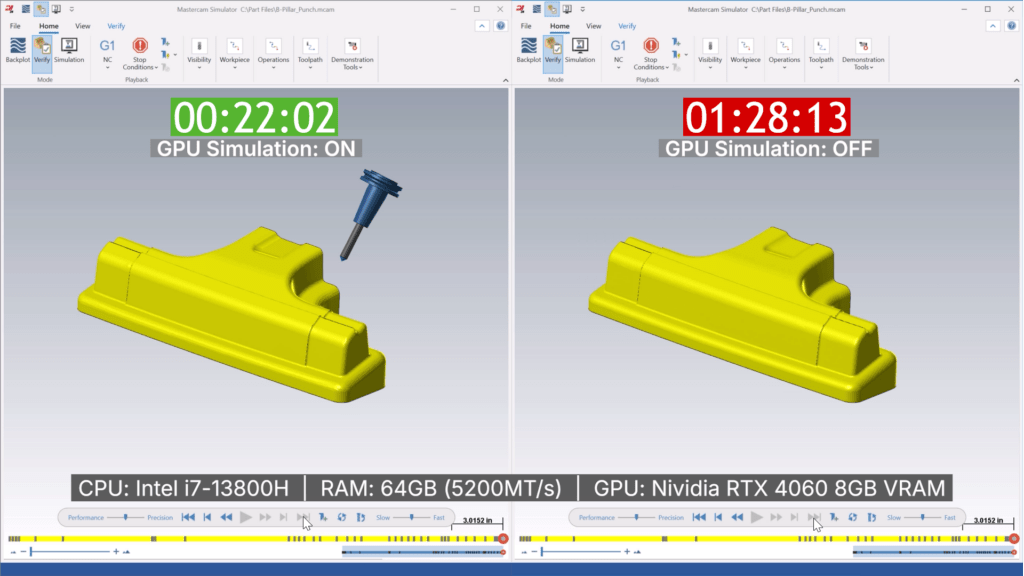

Why GPU Simulation Is a Breakthrough for Complex Parts — Now in Mastercam 2026.R2

If you've ever waited 90 minutes to verify a program that runs in 20, you already know the problem. Simulation is essential—nobody wants to prove out a toolpath by crashing into a fixture—but for complex multi-axis work, verification times have become a bottleneck that rivals the machining itself. Mastercam 2026.R2 changes that with GPU-accelerated simulation.

What We Learned: Mastercam Migration Webinar Recap

Staying current with Mastercam releases is not just about accessing new features, it is about protecting the customizations, workflows, and efficiencies shops rely on every day. During our “Mastercam Migration Made Easy” webinar, Mastercam’s Chad Chmura, walked attendees through the ins and outs of the migration process.

Mastercam CONNECT: Early Access to CAM Software Features

Manufacturing technology is evolving faster than ever and staying ahead means embracing change before it becomes mainstream. That is why we created Mastercam CONNECT, a platform designed to give you exclusive access to technical previews of upcoming Mastercam features. This isn’t just early access—it is your chance to influence the future of CNC programming.

Mastercam 2026.R2: Faster, Smarter, and AI-Powered —Here is What is Coming

New year, new release. Mastercam 2026.R2 arrives February 9 with features designed to give your shop a competitive edge.

Spot Drill vs. Center Drill: What is the Difference?

When setting up drilling operations in Mastercam, you may notice two similar tools in the filter: spot drills and center drills. While these terms are often used interchangeably, they serve very different purposes—and using the wrong one can lead to tool damage, poor hole quality, and inaccurate machining results. Let’s break down the differences and best practices for each. Understanding the Geometry Side by side,…

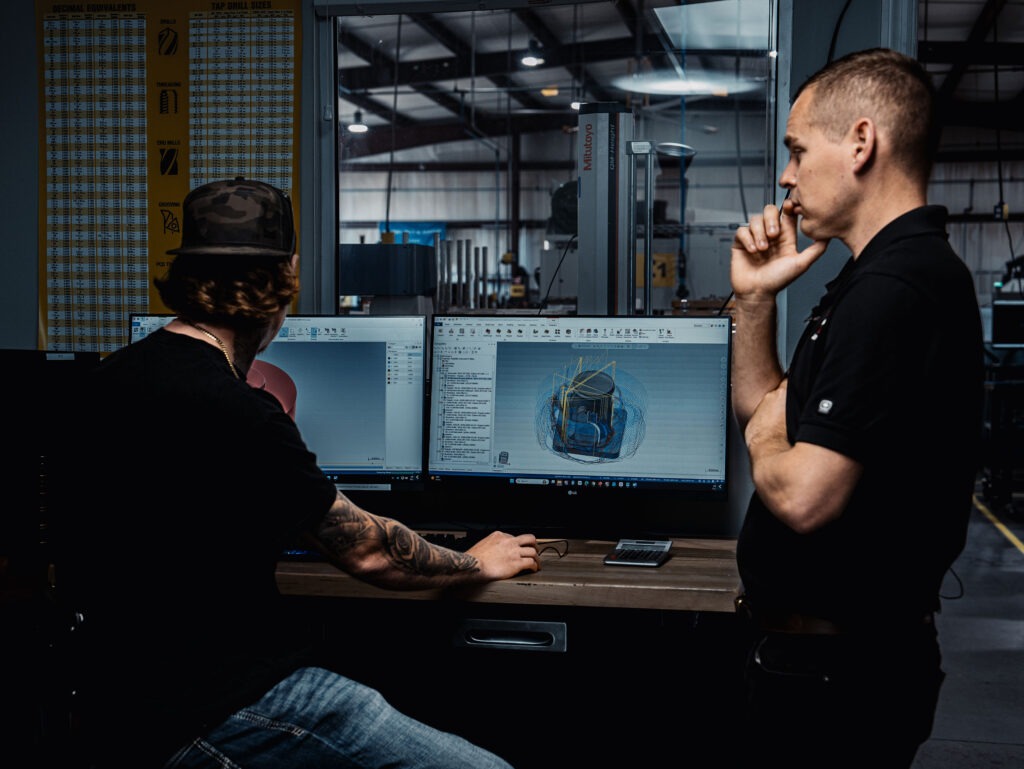

How Catamount Transformed its Aerospace Machining with Mastercam

Founded over 20 years ago, Catamount Machine Works has built a reputation for precision machining and uncompromising quality. Since its acquisition in 2018, the company has undergone a remarkable transformation—embracing advanced technology and process optimization to meet the rigorous demands of aerospace and high-end manufacturing. Business Transformation and Growth When Chris Basgall took ownership, Catamount was respected but limited in technological capability. His vision was…

What’s New in the Mastercam 2026 Planes Manager

If you have ever found yourself scrolling through a long list of planes trying to find the one you need, Mastercam 2026 has some good news. The Planes Manager has been refined with new organizational tools that help you spend less time searching and more time programming. Let's walk through what has changed and how to put these updates to work. New Ways to Create…

Mastercam 2026.R2: Power, Precision, and Productivity Redefined

At Mastercam, innovation begins with listening. That is why we are transitioning from an annual to a semi-annual release schedule, reflecting our commitment to delivering continuous value and responding more effectively to the evolving needs of modern manufacturing. Every feature in the second release of Mastercam 2026 is packed with features designed to accelerate workflows, improve accuracy, and simplify complex machining tasks—so you can focus…