Featured Stories

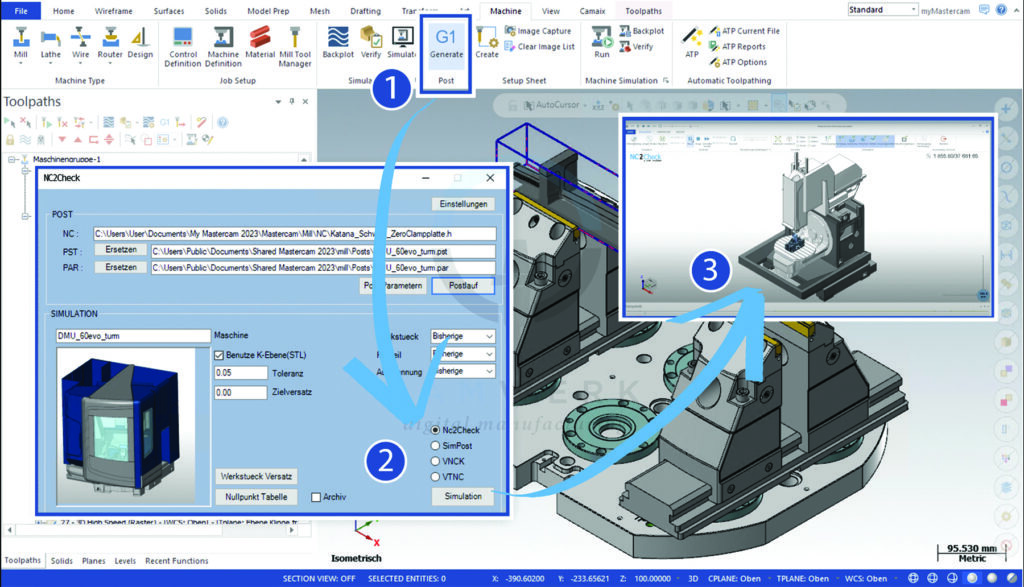

New Partnership Provides G-Code Simulation Within Mastercam

Simulate the entire machining process with the click of a button December 8, 2022 (Tolland, Conn.) – CNC Software, LLC, developers of Mastercam, the world’s leading CAD/CAM software, has partnered with CAMWERK to provide customers with the unique and easy to use fully-integrated machine solution called NC2Check. Mastercam developers worked closely with CAMWERK to build a solution for G-code simulation within Mastercam. The integration gives…

Collective Intelligence: An Insight into the Power of Collaboration

Over the past few weeks, we had the privilege of hosting 14 Sandvik brands at our headquarters in Tolland, Connecticut for a Collective Intelligence event. For several days, we collaborated on current projects, shared product roadmaps, product demonstrations, best practices, and identified areas of opportunity. We also made time for Swedish fika, of course. Want more information on how the week went? Keep reading. Product…

Get To Know a Mastercam Reseller: Meet MECAD

MECAD Systems has been the machining support company in South Africa since its foundation in 1989. From the very beginning, MECAD has been a Reseller of Mastercam CAD/CAM software, even when Mastercam was still a version running inside CADKEY. MECAD’s three branches in Johannesburg, Cape Town, and Durban are designed specifically to provide a far-reaching and wide range of technical support for sub-Saharan manufacturing shops.…

CAM Automation Tricks You Need to Know

The irony in automation is that it takes a lot of creativity to automate any process, but at the same time any automated process has zero inherent creativity – it is just a mindless repetition of preselected steps. While it is good for the process itself to be uncreative (no one wants their machining to go off-script), programmers themselves must often stretch their imaginations when…

What Coding Language Is Used on CNC Machines?

For anyone wondering whether or not they should control their CNC machines with hand-written code or with CAM-generated code, the first thing to do is to learn all about that coding language. Understanding what it is, how it’s made, and how to read it will make that decision easier. CNC Machining 101 Generating G-code can be done manually or with CAM software. Taking a part…

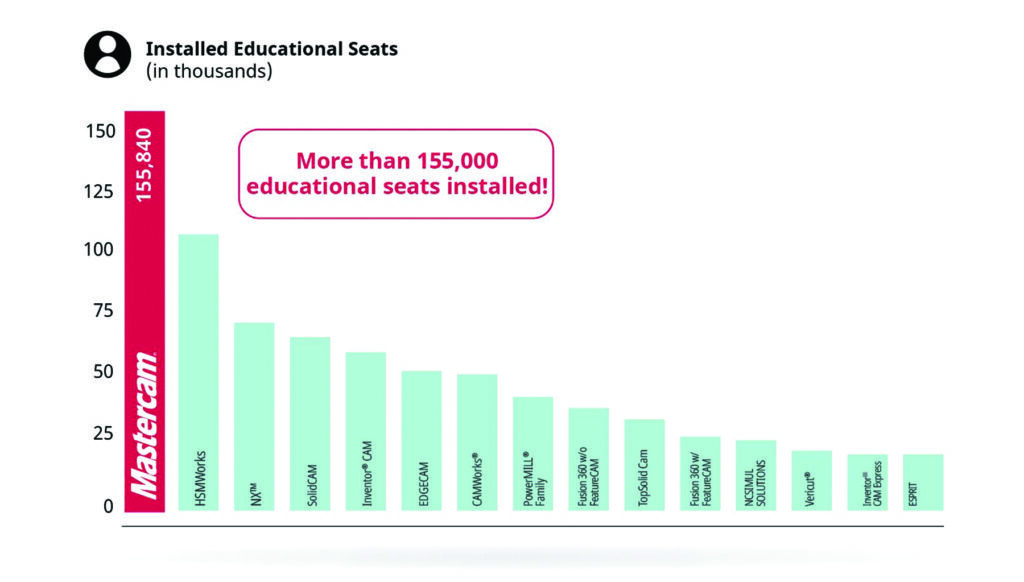

Mastercam Retains Top Ranking Worldwide

Mastercam is the most widely used CAM for the 28th year in a row September 19, 2022 (Tolland, Conn.) – More shops and schools invest in Mastercam than any other CAD/CAM software package in the world. According to CIMdata, Inc., an independent research firm specializing in the NC industry, Mastercam is the number one CAM software used worldwide for 28 years in a row, with…

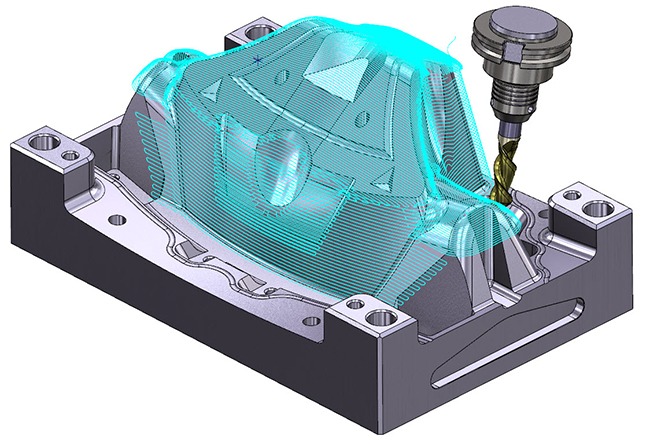

What is CAM?

CAM is computer-aided manufacturing (or computer-aided machining in some circles). It serves as the link between CAD and physical manufacturing, CAD being computer-aided design. After a designer or engineer creates a model of a part in their CAD program, they then export that file into a CAM system. This CAM system writes the code to control the manufacturing machinery that creates the part. It tells…

Mastercam & Sandvik Coromant: Feeding Each Other’s Expertise

The following is a guest blog written by Mastercam’s parent company, Sandvik Design & Planning Automation. Sandvik elaborates on how Sandvik and CNC Software have started sharing their expertise to find areas to collaborate. Sandvik Coromant, a leader in tooling, machining solutions, and knowledge, and Mastercam, an innovator in CAD/CAM software, are leveraging their expertise in joint efforts. They share the same passion for customers…

5 Things You Should Know About CNC Lathe Software

A computer numerical control lathe is directed by computer-generated code. This code tells the machine exactly where and how to cut, and it’s created by CNC software. When programmers need to find the best way to make a part on a lathe, they use their CNC CAD/CAM software to plan the machining motion. If you’re considering adding CNC lathe software to your shop, here are…

What Is the Difference between CNC Milling and CNC Turning?

CNC milling and CNC turning are the most commonly used machining styles in any given shop. Both rely on computer numerical control (CNC) programming, which directs the movement of a cutting machine along a predetermined path. Essentially, a CNC machine uses computer programming to cut away material in a specific way. The result is a part that is accurate and repeatable. Milling and turning differ…

What’s the Difference between CAD/CAM and 3D Printing?

NC code, CNC machines, G-code, CAD software, CAM software, 3D printing – even a quick dive into manufacturing will bombard you with terms like these. But what do they mean, and are they connected? This blog will piece apart three of the most commonly used terms in production circles today: CAD, CAM, and 3D printing. First, let’s define the three: CAD: computer-aided design; software that…

Learn How to Use CNC Software

Originally, machinists manually ran the mills, lathes, and routers that made their parts, manipulating the cutting path with their own hands. Then CNC machines were created to run on code that programmers handwrote. The result was more accurate machining but a more time-intensive prep stage and more opportunities for error. Imagine spending days writing out the code for a part only for one poorly entered…