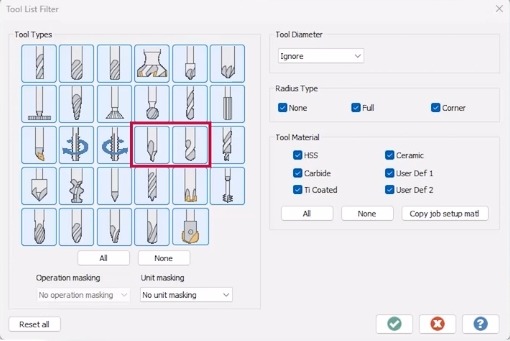

When setting up drilling operations in Mastercam, you may notice two similar tools in the filter: spot drills and center drills. While these terms are often used interchangeably, they serve very different purposes—and using the wrong one can lead to tool damage, poor hole quality, and inaccurate machining results. Let’s break down the differences and best practices for each.

Understanding the Geometry

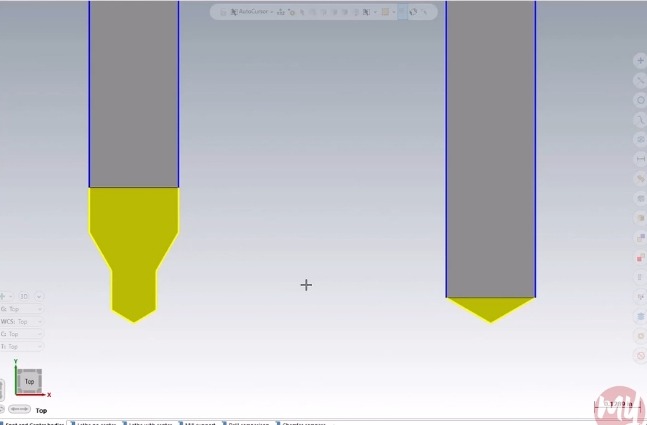

Side by side, the geometry tells the story:

- Center Drill (left): Designed for creating a divot that a lathe center can engage with.

- Spot Drill (right): Designed to create a starting point for a twist drill, preventing drill wander and improving hole accuracy.

What is a Center Drill Used For?

Center drills are not intended for spotting holes. Their purpose is to create a conical seat for a center, typically in lathe applications or occasionally in milling setups with rotary fixtures.

- Tip Diameter: Provides clearance and can hold lubricant for dead centers.

- Conical Face: Matches the center angle for proper support and alignment.

Using a center drill for spotting holes can cause problems:

- Twist drills have tip angles of 118° or 135°, while center drills are 60°.

- This mismatch means the drill edges hit first, causing chipping, torque issues, or drill breakage.

Why Use a Spot Drill for Drilling Operations?

Spot drills are designed for this job. Their angle is larger than the drill tip angle, ensuring the drill engages correctly at the center.

- Prevents drill walking.

- Reduces stress on cutting edges.

- Improves hole accuracy and tool life.

Pro Tip: Choose a spot drill with an angle slightly larger than your drill’s tip angle for optimal performance.

Other Applications for Spot Drills

Spot drills can also:

- Break the edge of a hole.

- Chamfer, if the angle isn’t critical.

- If the print calls for a specific chamfer angle, spot just under size, drill, then finish with a countersink tool.

When Should You Use a Spot Drill?

Not every hole needs spotting. For more on spot drilling best practices, check out our Show Me video on myMastercam.

Want to See This in Action?

Watch the full video in our Show Me section on myMastercam and explore more programming tips to optimize your machining process.

Key Takeaways: Spot Drills vs. Center Drills

- Never use a center drill to spot holes—their 60° angle doesn’t match twist drill tip angles (118° or 135°), causing drill edges to hit first and leading to tool breakage and chipping.

- Spot drills prevent drill wander and improve accuracy by creating a proper starting point with an angle that matches or exceeds your twist drill’s tip angle, ensuring the drill engages correctly at center.

- Center drills are designed exclusively for lathe work—they create conical seats for lathe centers in turning operations, not for spotting holes before drilling.

- Not every hole needs spotting—reserve spot drilling for holes requiring tight tolerances (±0.005″ or better), deep holes (depth > 3× diameter), angled surfaces, or hard materials.

- Spot drills can also break edges and chamfer holes when precise angles aren’t critical, making them versatile tools beyond their primary spotting function.