Your CNC router is only as good as its software—precision, speed, and efficiency all depend on it. Whether you are a seasoned machinist, a small business owner, or a hobbyist, choosing the right software can significantly impact your workflow and final product quality. With so many options available, finding the perfect fit can be overwhelming.

How do you know which CNC router software is the best for your needs? The ideal software should strike a balance between powerful design tools, seamless machine integration, and ease of use. That is where Mastercam shines. With industry-leading features, intuitive controls, and unmatched accuracy, it’s a top choice for businesses and individuals looking to optimize their CNC operations.

In this guide, we will explore the key features that make Mastercam stand out and why it remains a trusted choice among metal fabricators, woodworkers, engineers, and manufacturers.

Understanding CNC Routers and Software

CNC (Computer Numerical Control) routers have revolutionized industrial and commercial manufacturing by automating the cutting, carving, and engraving process with exceptional precision and efficiency. These computer-controlled machines are used to create highly accurate and detailed parts across various industries, from woodworking and furniture-making to metal fabrication, aerospace, and signage production. However, the true power of a CNC router lies in its software.

CNC software converts digital designs into precise machine movements, dictating every step of the machining process. From cutting speeds and spindle movements to toolpaths, the software ensures smooth, accurate, and repeatable results.

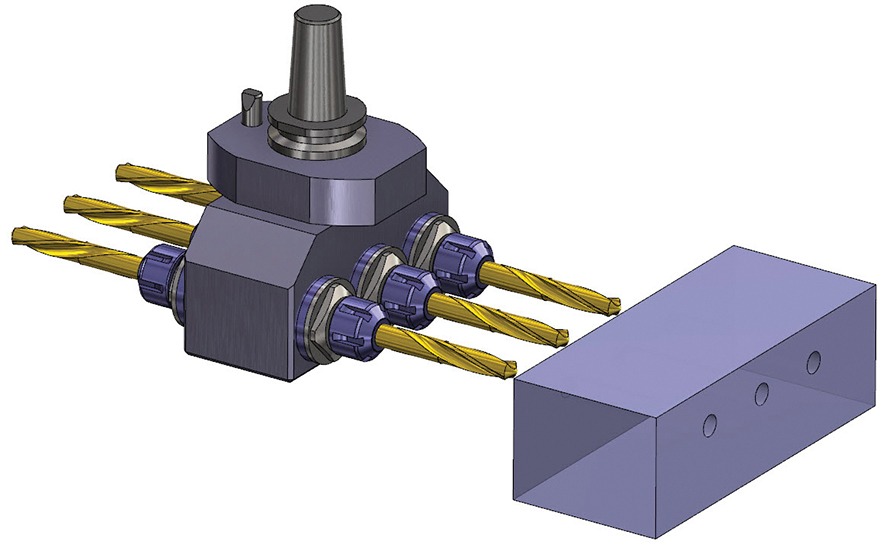

A CNC router can work with a variety of materials, including wood, metal, plastic, foam, and composites, making it a valuable tool for both small workshops and large-scale manufacturing facilities. Choosing the right CNC software is essential for maximizing efficiency, minimizing material waste, and optimizing production. With advanced toolpath control, automation, and precision, Mastercam Router stands out as a leading choice in modern CNC machining.

What software is needed for a CNC router?

A CNC router requires two main types of software: CAD (Computer-Aided Design) software to create digital designs and CAM (Computer-Aided Manufacturing) software to generate toolpaths and G-code for the machine. Programs like Mastercam Router integrate both functions, offering advanced toolpath control, automation, and precision cutting for optimal results.

What Makes the Best CNC Router Software?

The best CNC router software is a combination of power, precision, and ease of use, making it a crucial tool for both beginners and seasoned professionals. Whether you are crafting intricate designs, mass-producing components, or optimizing production workflows, the right software can significantly impact the quality, speed, and efficiency of your projects.

Key Features to Look For:

- User-Friendly Interface – Look for software that simplifies workflow, allowing operators to navigate complex machining processes with minimal learning curves. These features help ensure ease of use for beginners and professionals alike.

- Advanced Toolpath Creation – This helps to optimize cutting efficiency while reducing waste. Ensuring every cut is smooth, accurate, and optimized for minimal material waste.

- Native support for your router – Ensuring that the capabilities of your router are supported natively in the package.

- Reliable G-Code Generation – Ensures seamless communication between the software and the CNC machine.

- Simulation Tools – Allows users to preview, test, and refine toolpaths before running a job, minimizing errors and maximizing productivity.

These features collectively contribute to a streamlined, efficient machining process that saves both time and resources.

Among the numerous options available, Mastercam Router distinguishes itself due to its industry-leading toolpath strategies, intuitive interface, and automation capabilities. From woodworking and furniture design to aerospace and automotive manufacturing, Mastercam’s speed, precision, and versatility make it the top choice for professionals across a range of industries.

With its unmatched precision, speed, and versatility, Mastercam Router empowers users to produce high-quality, repeatable results.

Key Features of Mastercam CNC Router Software

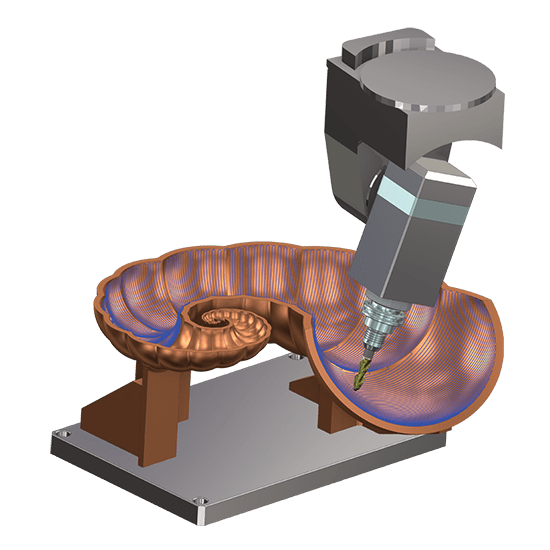

Mastercam Router software is designed for precision and efficiency, offering advanced toolpath strategies and intelligent control software to deliver professional-grade results.

Precision & Efficiency

Mastercam Router is built for professional-grade results, offering advanced toolpath strategies and intelligent control software. Its powerful algorithms generate precise G-code, allowing users to fine-tune cutting speeds and tool movements for maximum accuracy. By automating complex machining processes, Mastercam helps manufacturers improve productivity while maintaining the highest quality standards. Whether you’re creating intricate designs or managing high-volume production, Mastercam ensures smooth, optimized cuts with minimal material waste.

Customization & Compatibility

Mastercam is compatible with a wide range of CNC routers and machining environments. It allows users to customize speeds, feeds, and toolpath parameters, adapting the software to their specific production needs.

Industry-Leading Support

Mastercam provides extensive training resources, an active user community, and expert assistance to help users maximize their software potential. Whether you’re a small shop or a large-scale manufacturer, Mastercam ensures you have the tools, support, and adaptability to optimize your CNC workflow.

What software is best for CNC programming?

Mastercam is a top choice due to its advanced toolpath strategies, precision G-code generation, and industry-leading automation features. It offers powerful CAD/CAM integration, compatibility with various CNC machines, and extensive support resources, making it ideal for both beginners and professionals.

CNC Projects Made Easy with Mastercam

Mastercam simplifies CNC projects across a wide range of industries, from large-scale manufacturing to intricate custom woodworking. Whether you’re producing high-precision aerospace components, crafting detailed furniture, or engraving signage, Mastercam’s powerful toolpath strategies and automation features ensure smooth and accurate execution. With its user-friendly interface and advanced CAM (Computer-Aided Manufacturing) capabilities, the software allows users to optimize cutting speeds, reduce material waste, and streamline production workflows.

Step-by-Step CNC Workflow with Mastercam:

- Create or Import a Design – Use Mastercam’s CAD tools or import external files.

- Define Toolpaths & Cutting Parameters – Optimize settings based on material and machine type.

- Simulate & Optimize – Use Mastercam’s simulation tools to preview cuts and prevent errors.

- Generate & Export G-Code – Send precise machine instructions to your CNC router.

- Execute & Monitor – Run the job with confidence, knowing Mastercam has optimized the process.

This step-by-step approach minimizes errors, increases efficiency, and ensures consistent high-quality results for every project, making CNC projects easier and more accessible than ever.

Why Choose Mastercam Over Other CNC Software?

When comparing Mastercam to alternatives, it becomes clear why it is the industry leader in CNC programming and manufacturing efficiency. Many CAM packages for CNC routers are limited in scope, but with Mastercam, you have the flexibility to do more. From simple 2D programming to complex 5-axis machining, the world’s leading CAM software helps get the best performance out of CNC routers.

Beyond its powerful toolpath strategies, Mastercam significantly enhances production speed, machine efficiency, and ease of use. Its intelligent automation tools help reduce material waste, while its intuitive interface makes complex machining processes more accessible. The software’s robust simulation features allow users to preview cuts before execution, minimizing costly mistakes and ensuring high-quality results.

Whether you are a small shop or a large-scale manufacturer, Mastercam provides the tools you need to increase productivity and precision. Ready to take your CNC machining to the next level? Explore Mastercam today and experience the difference firsthand!

Key Takeaways

- CNC routers rely on advanced software to translate digital designs into precise machine movements, ensuring accuracy and efficiency in manufacturing processes.

- A CNC router requires both CAD software for design and CAM software for generating toolpaths and G-code, with Mastercam offering a seamless integration of both functions.

- The best CNC router software combines powerful design tools, ease of use, and automation, with Mastercam excelling in all three areas for optimal machining results.

- Mastercam simplifies CNC projects with step-by-step guidance, robust simulation tools, and optimization features for superior cutting accuracy and efficiency.

- With its industry-leading reputation, powerful features, and ease of use, Mastercam remains the best CNC software choice for businesses and professionals in 2025.