No Room for Error: Delivering Mission-Critical Projects with Mastercam

Where Precision Meets Pressure

For Catamount Machine Works, manufacturing precision parts for the defense industry demands absolute accuracy. The stakes are high, and failure is not an option.

Overview

Producing high precision components for the defense industry with zero-margin-for-error execution that are AS9100 and ITAR compliant.

Utilizing advanced 5-axis machining, Wire EDM, and CNC lathe equipment, powered by Mastercam and its local support team.

Adoption of 5-axis machining increased from 0% to 40%, wire EDM setup time was reduced by 25%, and revenue from complex, previously unachievable projects grew by 32%.

Project Details

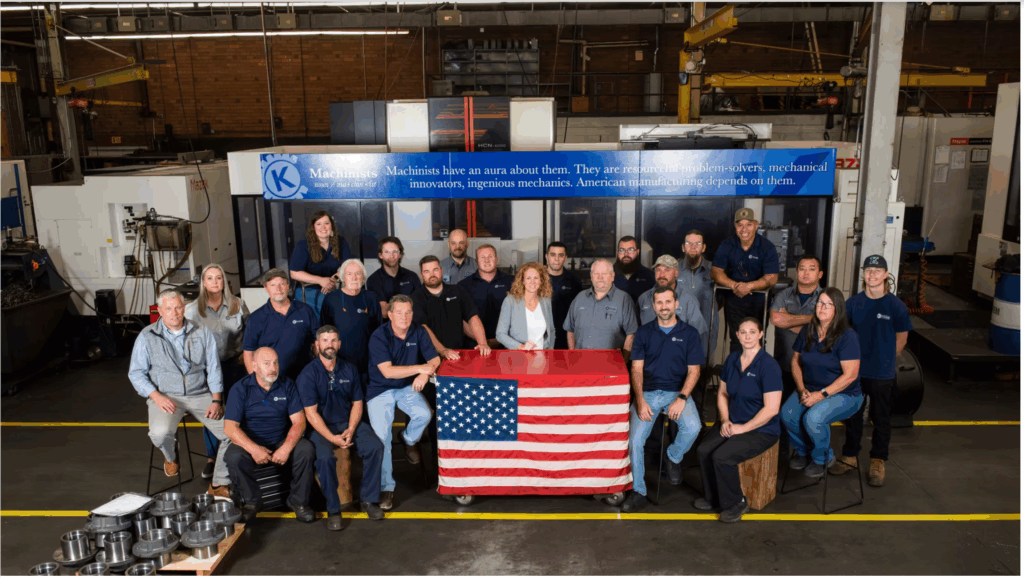

Every component Catamount Machine Works produces has to meet an unforgiving standard. With around 85% of its manufacturing focused on military applications, the company operates in an environment where precision is a must.

This line of work comes with steep demands. An AS9100 certification is not optional in defense or aerospace. It is proof that a business meets the strictest standards for quality, traceability, and documentation. ITAR compliance adds another layer, safeguarding sensitive defense data under U.S. export laws.

When it came time to upgrade their CAM system, Catamount Machine Works CEO, Chris Basgall, said the decision was clear. After testing competing CAM software, the team found it unreliable and expensive to train on, resulting in costly production errors. At the same time, Basgall notes, retaining skilled programmers has become a top priority as competition for tech talent continues to grow.

They needed a system that was not only powerful, stable, and precise but also intuitive enough to attract and retain top-tier talent. That is exactly what they found in Mastercam.

Basgall says the teamwork at his company is built with a clear vision: standardization, efficiency, optimization, and advanced technology. “Mastercam is at the foundation of our strategy because if you can not get the programming right, nothing else is going to be right,” he says.

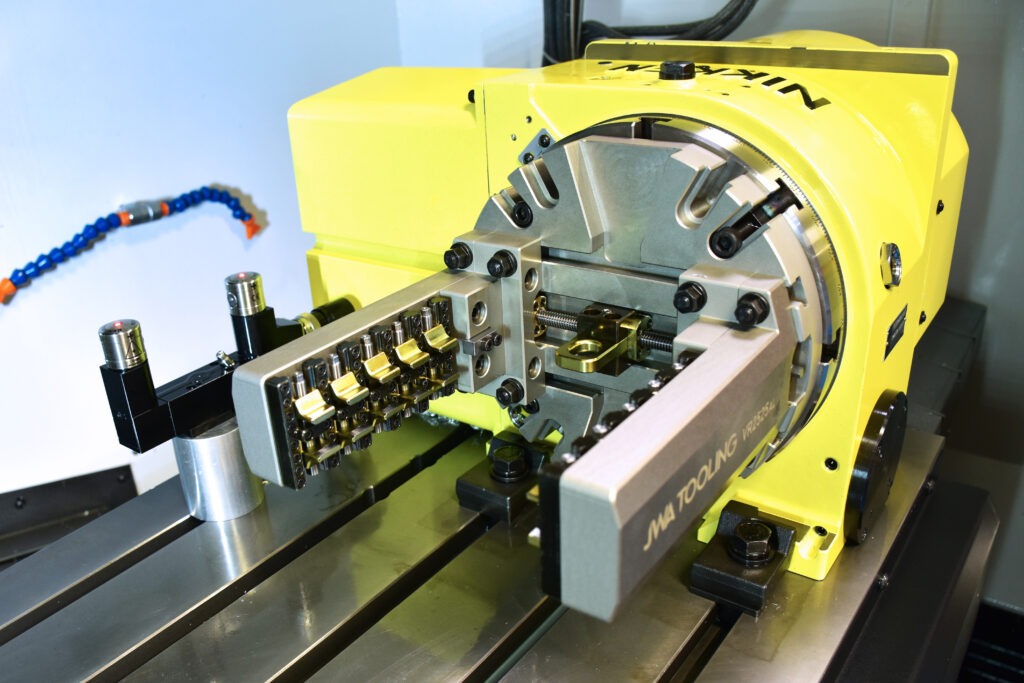

Partnering with Mastercam, the company was able to upgrade and expand functionality for 5-axis machining, wire EDM, and lathes. In fact, the company went from zero use of 5-axis to about 40% in a short period of time.

With Mastercam, the team operates in a fully AS9100 and ITAR-compliant environment. It also meets NIST 800-171 and CMMC cybersecurity standards, ensuring sensitive information stays secure.

Basgall praises Mastercam’s robust support system. “We cannot afford to wait hours for an answer in the middle of a project,” he says. “With Mastercam, we have local, regional, and HQ support.” Mastercam’s intuitive interface also helps Basgall’s team train each other on the latest advancements and retain skilled programmers.

“We cannot afford to wait hours for an answer in the middle of a project. With Mastercam, we have local, regional, and corporate support.”

Precision in Action

Catamount Machine Works was tasked with making uniquely complex brackets for a submarine with no room for error. “When you are building critical components for submarines and aircraft, ‘close enough’ does not cut it. Every cut, curve, and hole needs to be exact down to two-tenths of a thousandth of an inch. That is like splitting a human hair… several times,” said Basgall. “It is precision engineering at its most extreme.”

They used a setup called 3+2 machining (a technique where the tool moves in 5-axis, but cuts in 3 at a time) and programmed it all using Mastercam. It worked.

In another example, the company used precision Wire EDM to manufacture parts for missile guidance systems, where tight tolerances are essential. Programming with Mastercam’s software helps maintain the predictability they need while managing the high operating costs of the equipment.

Catamount Machine Works also uses robots to run high-volume jobs around the clock. Once a part is programmed and set up, the team directs the robots to load and unload a pallet of parts, often stacked high enough to keep production going all weekend without interruption.

With Mastercam, the company can deliver consistent output for everything from aerospace and defense components to automotive parts.

An Ecosystem Built for Precision, Speed, and Scale

Basgall likes that Mastercam consistently delivers enhancements year after year, and when updates roll out, the solutions work as expected. Catamount Machine Works also uses Verisurf, a model-based metrology solution to improve quality and streamline production. As part of Mastercam’s ecosystem, Verisurf’s metrology solutions integrate seamlessly.

Having one standardized software platform means:

- Shorter programming time

- Fewer mistakes

- Easier training (so team members could help each other quickly)

- Faster turnaround on parts

- Higher revenue and profits

- Happier customers

And the results speak for themselves. One of their largest aerospace clients, an industry giant, rates them with a 100% on-time delivery and quality score. They have cut Wire EDM setup time by 25% and complex jobs that were previously unachievable have increased by 32%.

Moving Forward

Basgall expects the next five years to bring rapid change in manufacturing, driven by AI and advanced automation. He says shops that embrace this shift, rather than resist it, will have a competitive advantage.

With Mastercam as its strategic partner, Basgall’s team is embracing intelligent, connected manufacturing, backed by the industry leader in this space. And as the manufacturing landscape evolves, Catamount Machine Works is stepping confidently into the future.

Quick Facts

- Product Used: Multiaxis, Wire EDM, and Lathes

- Industry: Defense, aerospace, and automotive