Top 5 Features in Mastercam 2026 to Increase Productivity

Top 5 Features in Mastercam 2026 to Increase Productivity

Welcome to Mastercam 2026! The latest release is here to elevate your machining experience. With feedback from users and shops worldwide, we built upon our past advancements and are excited to bring you our most intuitive interface yet. Mastercam 2026 includes various improvements allowing you to increase productivity, complete tasks quicker, more accurately, all while…

8 Multiaxis Features to Discover

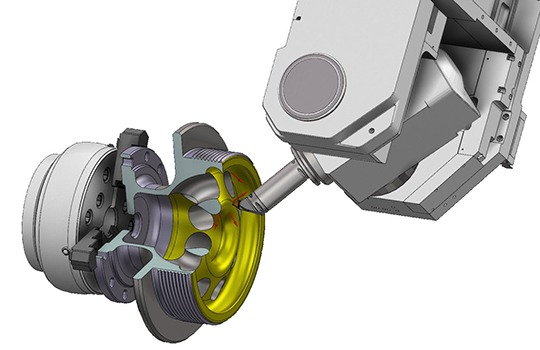

Mastercam Multiaxis is designed to provide practical multiaxis machining strategies for simultaneous 4- and 5-axis machining. It’s available for add-on for Mastercam Mill 3D, Mastercam Router 3D, and Mastercam Mill-Turn. As more shops incorporate multiaxis practices, we have invested more in improving our Multiaxis product. Explore these multiaixs tools and features, which were created with…

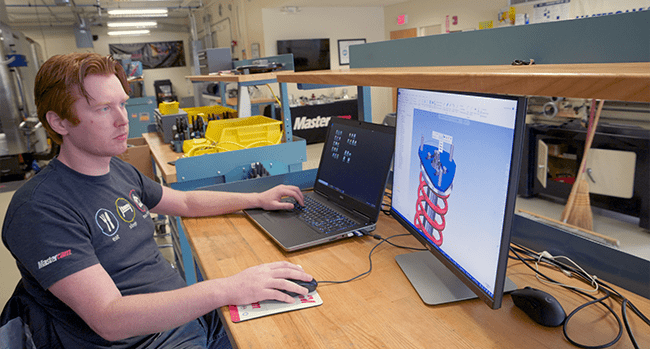

From Classroom to Career: The Impact of Mastercam’s Education Programs on the Manufacturing Industry

In the evolving world of manufacturing, the role of education is more critical than ever. At Mastercam, we are dedicated to addressing the industry's challenges by equipping the next generation with the skills and knowledge they need to succeed. We were fortunate enough to speak with Clint Smith, Sr. Education Market Specialist at Mastercam, whose…

CAM Trends for 2025 – Doing More with Less

By Dave Miller, Manager of Sales Engineering, Mastercam In the manufacturing field today, sticking to “the way we’ve always done it” just won’t cut it anymore. With cutting-edge tools like AI, IoT-enabled equipment, and advanced CAM software reshaping the shop floor, agility and interconnectivity will be key to successfully reimagining traditional processes. If you’re ready…

A Closer Look: Creating the Nike of Samothrace Statue

The Winged Victory or Nike of Samothrace is a statue prominently featured in The Louvre Museum in Paris, France. Mastercam recently teamed up with YASDA Precision, Mitsubishi Materials, and Methods Machine Tools to create an 11-inch replication of the famed 18-foot statue. Within Mastercam, the statue is a mesh file with over five million facets…

A Closer Look: Creating the Mastercam Gingerbread House with Hermle

Mastercam proudly teamed up with our partners at Hermle to create a gingerbread house to celebrate the winter holiday season. When we approached Hermle with the idea of creating this festive piece, Kyle Brunner, Senior Applications Engineer at Hermle, was excited to get started and said the gingerbread house “belongs on a Hermle.” Working with…

Have You Tried These New Mastercam 2024 Multiaxis Features?

As more and more shops adopt multiaxis practices, we have invested more in improving our Multiaxis product. Explore these three new Mastercam 2024 Multiaxis tools, created with users like you in mind. Colored Selection Display Multiaxis In Mastercam 2024, many geometry selections are now viewable in the graphics screen immediately upon entering a multiaxis path.…

What the Mastercam-Robotmaster® Partnership Means for You

As of January 2023, robot programming tool Robotmaster® provides additional support for Mastercam CAD/CAM software products. Together, the two provide seamless integrated functionality between specialized, CNC machining-focused CAD/CAM programming and CAD/CAM robot programming. See how this partnership can benefit you and your shop. What is Robotmaster Software? The Robotmaster product, created…

Have You Tried These New Mastercam 2023 Multiaxis Features?

As more and more shops adopt multiaxis practices, we have invested more into improving our Multiaxis product. Explore these three new Mastercam 2023 Multiaxis tools, created with users like you in mind. Unified Multiaxis Toolpath Boosting efficiency begins the moment a part file is opened in Mastercam. Instead of requiring a user to spend extra time…

Multiaxis FAQs with Multiaxis Product Owner Dylan Gondyke

Dylan Gondyke is the Mastercam Multiaxis Product Owner. He grew up in Eastern, Connecticut and entered the manufacturing industry at the age of 16, where he was immediately drawn to programming and process automation. His early experiences during the technology shift of the mid-2000s spurred a passion for building better tools and workflows for the…

5 Ways to Improve Productivity with 5-axis Machining

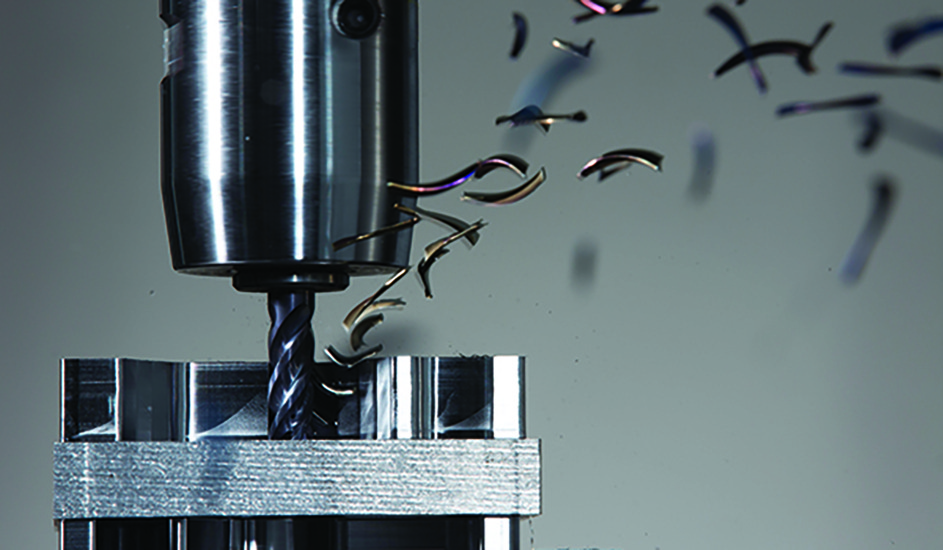

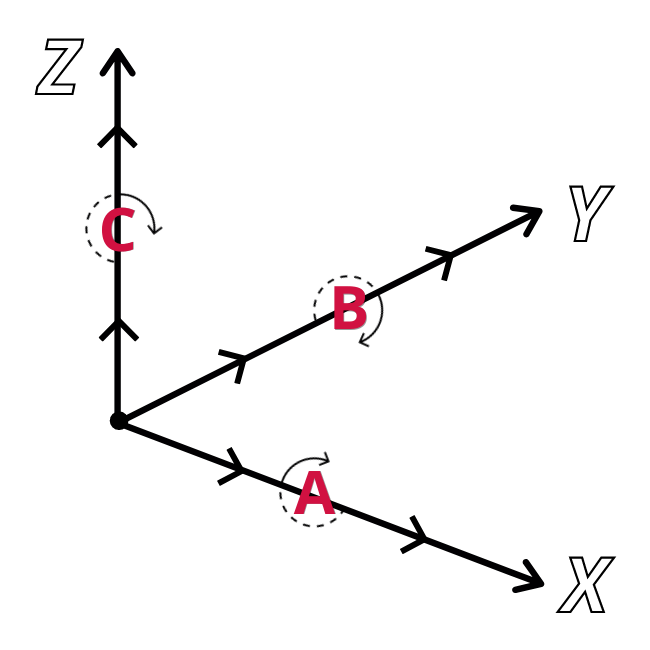

Multiaxis machining is defined by the motion of the cutting machine. A multiaxis machining center can move either its cutting tool or workpiece not only along the three basic linear axes (X, Y, and Z), it can also use the rotary axes (A, B, and/or C) around each of the linear axes. With 5-axis machining, programmers can…

What are the Axes in 5-Axis Machining?

Five-axis machining is taking the machining world by storm, and for good reason. This type of manufacturing, in which computer numerical control is used to move cutting parts or tools along five different axes simultaneously, unlocks incredible potential for any shop. Five-axis machining reduces labor hours, eliminates extra setups, increases production efficiency, and results in beautiful…