Why Use Accelerated Finishing?

Accelerated Finishing Technology Gives You New Ways To Work Faster

Our cutter-specific strategies are designed to make the best use of the latest advances in tool types and shapes. These tools need specialized, precision control to use them safely and to their full benefit. As new tool designs continue to emerge, technology must evolve to optimize performance.

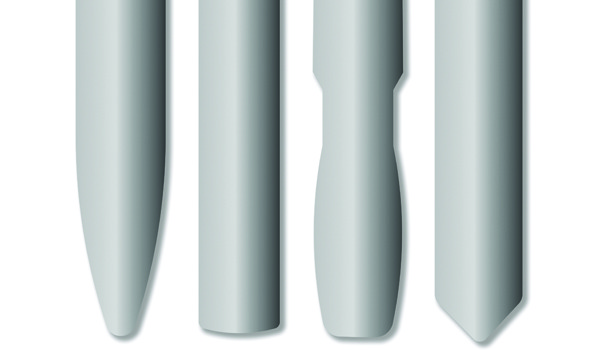

Accelerated Finishing® is developed in conjunction with the most advanced, new cutting tool shapes. These include oval form cutters, barrel mills, taper cutters, lens-shaped cutters, and lens barrel form tools. Our toolpath strategies enable a large effective cutting radius for small diameter tools.

When you use Accelerated Finishing, you can take advantage of the new cutting tool designs and the benefits they offer to reduce cycle time and improve surface finish.

How Does Accelerated Finishing Work?

Accelerated Finishing is a cutting method that delivers a higher quality surface in less time than traditional finishing techniques. It will help to look at Accelerated Finishing compared to traditional finish machining to understand the advantages.

Traditional finish machining is the most time-consuming segment of any CNC milling project. It is also the most important. Typically, 3D surface finishing is a compromise between surface quality and cycle time where higher quality equates with longer cycle time.

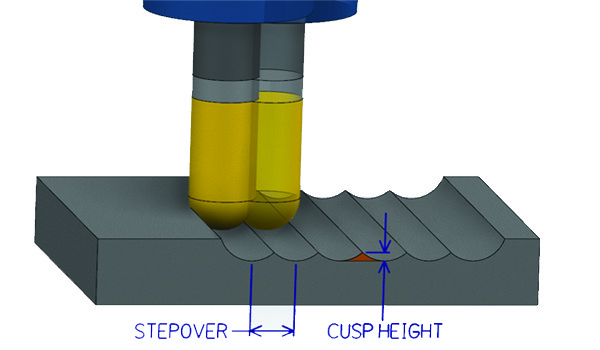

Cusp height is a factor that has a tremendous effect on surface quality. It is a function of cutting tool radius and stepover/stepdown where smaller cusp height equates with better surface finish. Two ways of reducing cusp height are by decreasing stepover and increasing cutting edge radius.

The traditional approach to improve surface finish is to decrease stepover. This approach not only increases cycle time but also the NC file size.

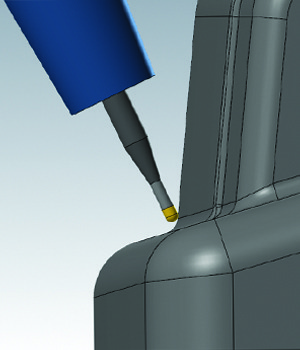

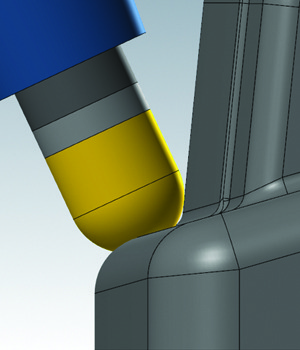

In contrast, increasing cutting edge radius will achieve a far better surface for a given stepover with no increase in cycle time. However, increasing cutting edge radius with a traditional ball endmill can cause problems with reduced reach in tight areas and potential for collisions with the model.

This is where new tool profiles and Accelerated Finishing Technology can help.

Plus, this concept is not limited to Multiaxis applications. For example, you can achieve similar benefits on 3-axis molds with drafted walls. All of Mastercam’s 3D HST finishing toolpaths support Accelerated Finishing, so a Multiaxis license is not required for their use in a 3-axis machine.

Here are videos of Accelerated Finishing Technology in action:

B-Pillar Punch

Docking Ring

Sorting Slider: Accelerated Finishing

If you are a Mastercam user, here’s how you can get started with Accelerated Finishing Technology:

- Visit the Mastercam Tech Exchange, community.mastercam.com/TechExchange.

- Select the ‘Tool Libraries’ tab.

- Search for ‘Accelerated Finishing’.

- Download free Accelerated Finishing Tool Libraries for Mastercam.

You can also download the B-Pillar Punch or Docking Ring part files from the Tech Exchange.

Learn More About Accelerating Finishing Technology

If you have any questions or would like to learn more about the benefits of Accelerated Finishing Technology, please contact your local Mastercam Reseller today.