Multiaxis

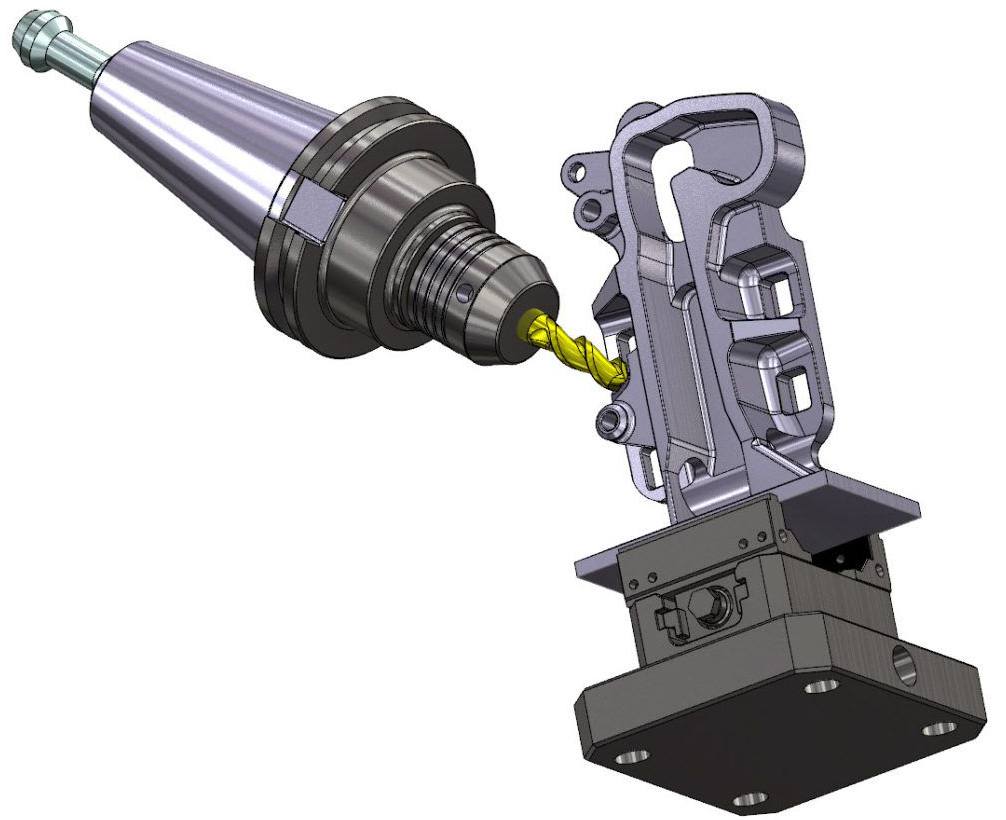

Improve your productivity with simultaneous 4- and 5-axis machining capability for Mastercam. Mastercam Multiaxis offers a wide range of multiaxis machining strategies—both basic and advanced.

Multiaxis toolpaths are also very useful for advanced control on 3-axis machines. With Mastercam, you have complete control over three crucial elements of multiaxis machining: cut pattern, tool axis control, and collision avoidance.

- Delivers multisurface 5-axis roughing and finishing, including stock model awareness.

- Tilt axis limits control the tool angle to ensure the toolpath will not gouge your part or violate machine tool limits.

- Advanced gouge-checking and a 5-axis safe zone around the part help ensure safe cuts in even the most complex operations.

- Works with Mastercam Mill 3D, Mastercam Router 3D, and Mastercam Mill-Turn products to generate 5-axis code to run virtually any CNC machine.

- Support for advanced tool geometries is included as standard.

Mastercam Multiaxis ensures accurate cuts and fast turnaround on even the toughest jobs, with streamlined multiaxis programming for optimum productivity.

Contact a Reseller

To learn how Multiaxis can enhance your productivity, contact your local Mastercam Reseller for more information.