Mastercam 2023 is the latest edition of the world’s leading CAD/CAM software, intentionally upgraded to make programming fast and easy. It prioritizes streamlining workflow so that the entire machining process – from design to QC – is as efficient as possible. Explore these six tips and features to help you maximize the benefits of Mastercam 2023.

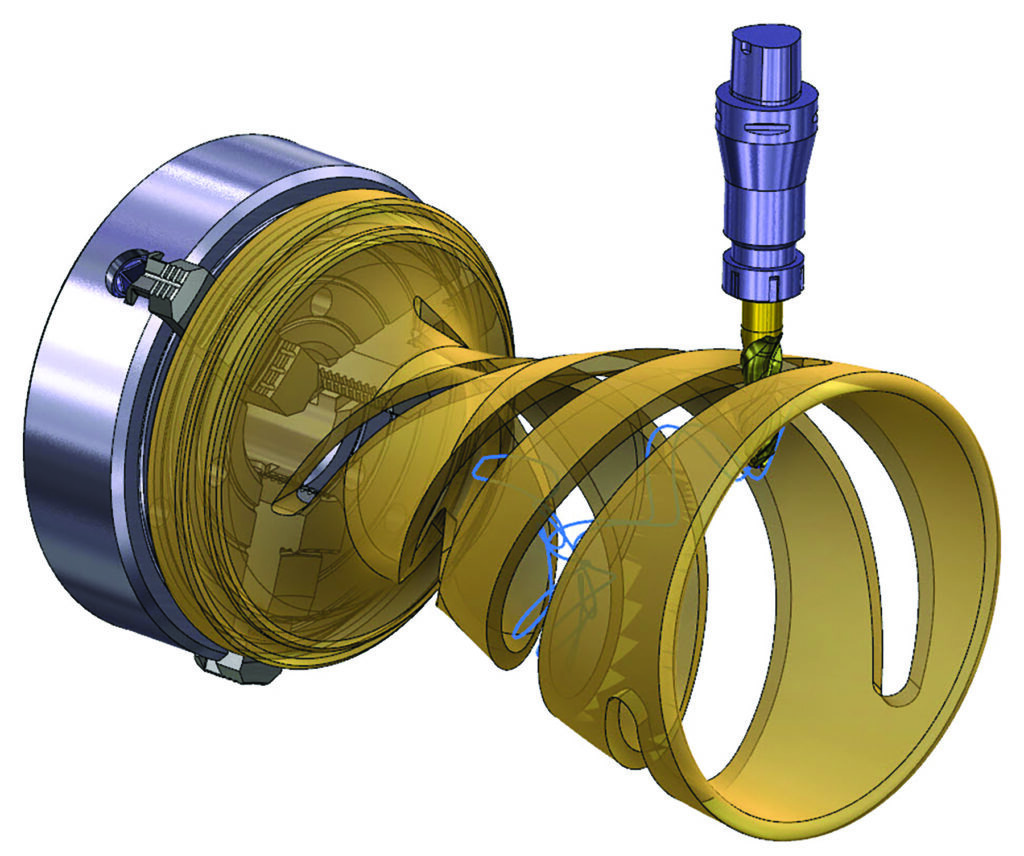

1. Unified Multiaxis Toolpath

Imagine almost completely programming a Morph toolpath for a particularly tricky component, only to realize that Parallel really would have worked much better. Having to scrap all that work and rebuild a toolpath from the ground up is not only frustrating, it’s a costly time loss.

Enter the Unified Multiaxis Toolpath. It combines all of the multiaxis operations and surfacing applications of Multiaxis into one simplified toolpath. Users no longer have to use Morph, Parallel, Along Curve, and Project curve separately, because they are all integrated in this comprehensive toolpath with a consolidated, easy-to-use interface.

So when mistakes happen, programmers can simply switch the cut pattern. There’s no losing the previous settings or reselecting a toolpath to map from scratch. Not only does this slash programming time, it also allows for incredible flexibility in cut pattern. For shops bringing in more employees, this is especially helpful; now there is only one toolpath interface to learn for all multiaxis operations.

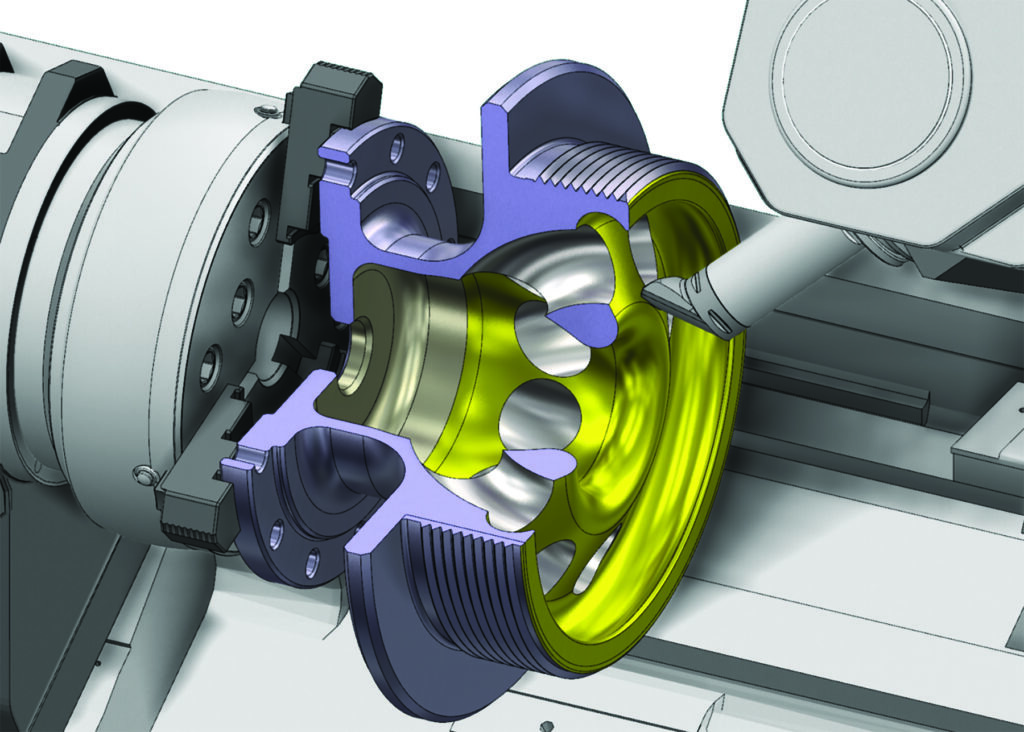

2. B-Axis Contour Turning

B-Axis Contour Turning hijacks multiaxis technology for the Mastercam Mill-Turn product. This Turning toolpath allows for the rotation of the B-axis while the tool is cutting. Functionally, this tilts the turning tool dynamically during machining to access undercut or other difficult areas.

Without the B-Axis Contour Turning Toolpath, the same areas would have otherwise needed multiple setups, tools, and blends, fragmenting machining and reducing overall finish quality. Now users can achieve far superior finishes in less time

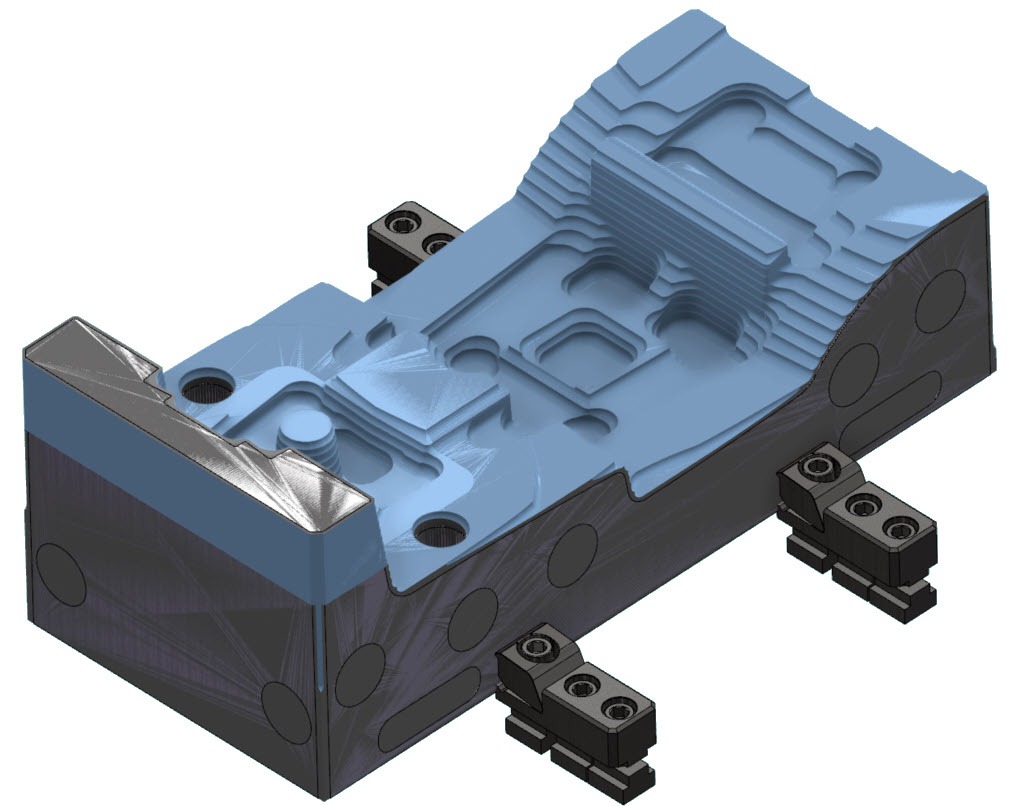

3. Machine Group Setup

The new Machine Group Setup function panel for Mill and Router machine groups makes setting up jobs, from stock to simulation, easier and more organized than ever. It combines all the features and functionality of the Machine Group Properties dialog box – along with new features – and presents them in a clean, intuitive function panel. Every critical component of job setup is readily available here.

Within the panel, users can define stock, material properties, work-holding, tools, and simulation settings. The graphics view now even works for setting up work-holding assemblies. Part components can be imported directly into Machine Group Setup and positioned within the interface. Machine Group Setup also introduces the concept of Master Model, a stock-aware feature that better replicates the finished part for programming and simulation.

4. Equal Scallop Stock Awareness and Step-Ins

The Mastercam 2023 Equal Scallop is the perfect intermediary between roughing and finishing. Many if not most 3D parts will have leftover material hiding in corners after initial roughing. This usually requires additional passes with smaller tools, a process that adds significantly to cycle times. Not so with Equal Scallop. All users have to do is define the step-in distance (this controls the amount of stock removed) and maximum step-ins, and then Equal Scallop automatically finds and removes material left in corners with safe, iterative passes.

5. 3D Rough Linking

Roughing has once again been improved for faster, more efficient cutting strategies. The new Linking Parameters pages was introduced with the previous version of the software, Mastercam 2022. The page was designed to improve high-speed 3D finishing toolpaths. With Mastercam 2023, Dynamic OptiRough, Area Roughing, and Horizontal Area toolpaths also benefit from linking. The difference is in the transition between passes, when the cutting tool is in the air and not engaged with material, and how linking minimizes this air cut time. In this way, more time is spent removing material instead of moving around the part.

6. Grouping Viewsheets

Sometimes the simplest way to streamline workflow is by tracking processes visually. In Mastercam 2023, users can create viewsheet groups to reduce onscreen clutter and organize viewsheet data. The most complex and sophisticated part assemblies will naturally require a daunting number of viewsheets. Holding them all onscreen or riffling through them to find one specific piece of information is overwhelming and, frankly, a waste of time. Now users can color-code groups of viewsheets, minimize and expand them, and reorganize them with minimal mouse miles.

Learn More

If you’re serious about streamlining the workflow in your shop, your local Reseller is one of your most valuable assets to talk to about upgrading to Mastercam 2023. Reach out to one here.