Mastercam 2023 is here to elevate your machining experience with powerful toolpaths, faster organized set ups, flexible tool motion, and our most intuitive interface yet. Here are the top 10 new Mastercam 2023 features — and how they can help you.

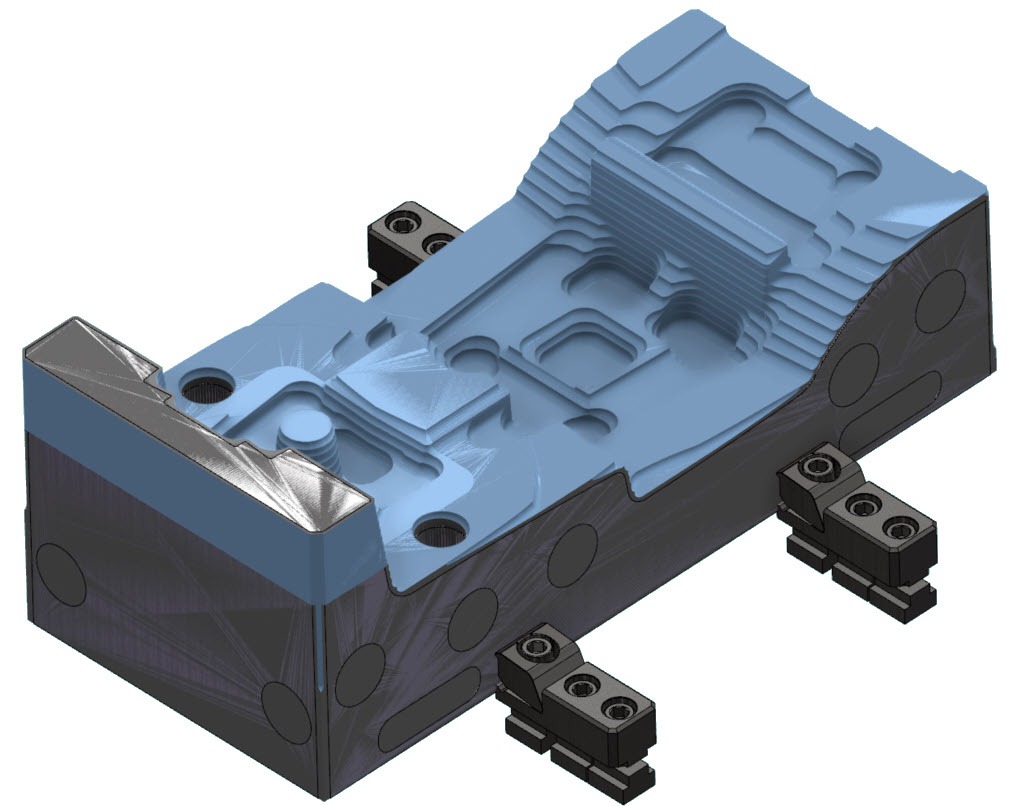

1. OptiRough Detecting Undercut Stock When Machining

In Mastercam 2023, achieving optimized motion is a matter of turning on a switch. The Dynamic OptiRough and Area Roughing toolpaths can now be aware of undercut stock conditions when rest machining. This results in improvements to the toolpath motion, including less air cutting.

2. Unified Multiaxis Toolpath

Morph, Parallel, Along Curve, and Project Curve are no longer individual toolpaths in Mastercam 2023. Users can now find the same functionality inside the Multiaxis Unified toolpath. Unified allows for far more flexibility in cut pattern when programming Multiaxis, all within a new advanced feature set and consolidated, easy-to-use interface.

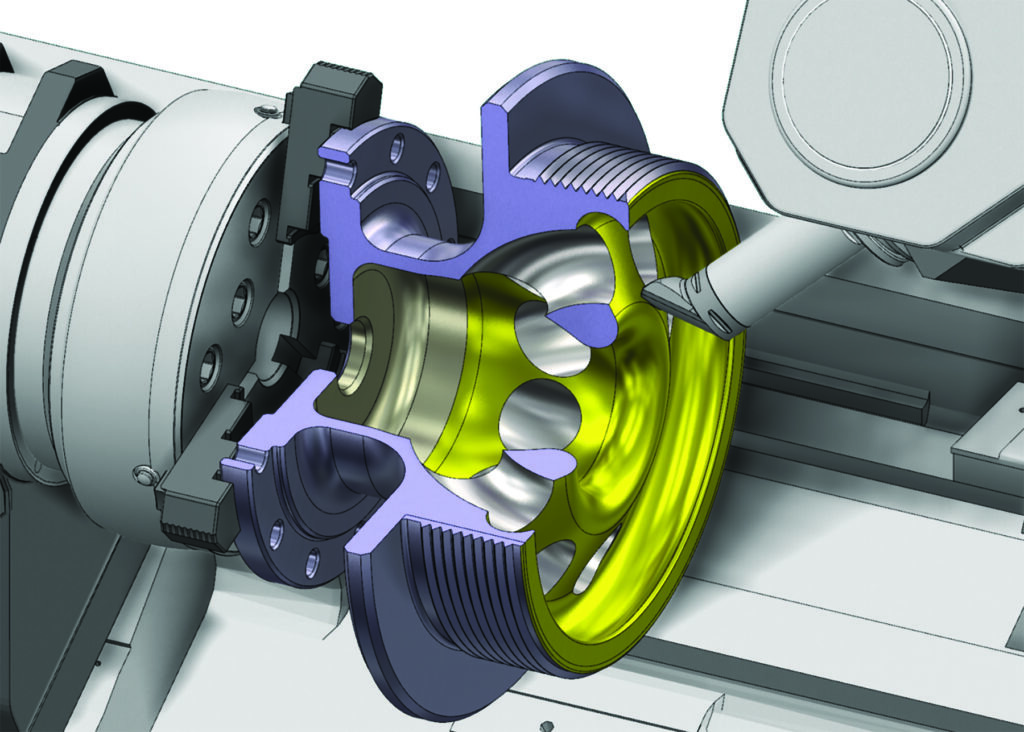

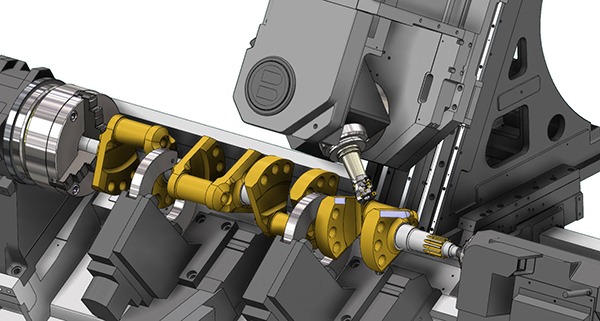

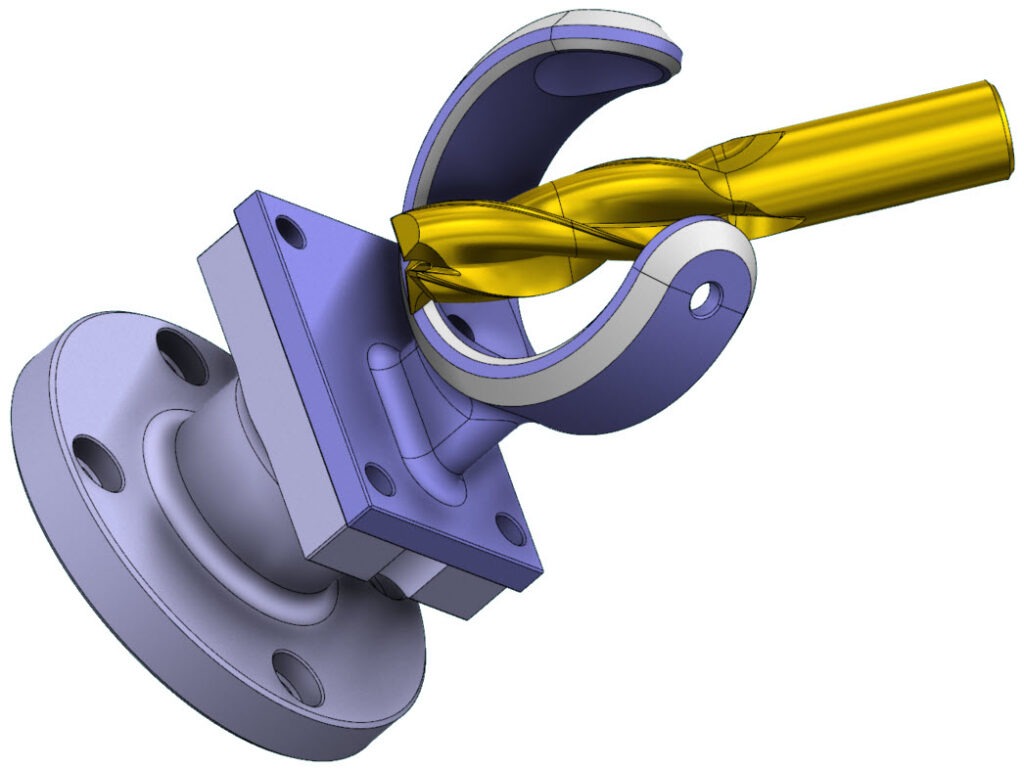

3. B-Axis Contour Turning Toolpath

One of our favorite Mastercam 2023 features: the new B-Axis Contour Turning toolpath. It allows for rotation of the B-axis while the lathe or turning tool is cutting. This means fewer tool changes and less cycle time. Users can now knock out difficult-to-reach areas and access undercut with one tool.

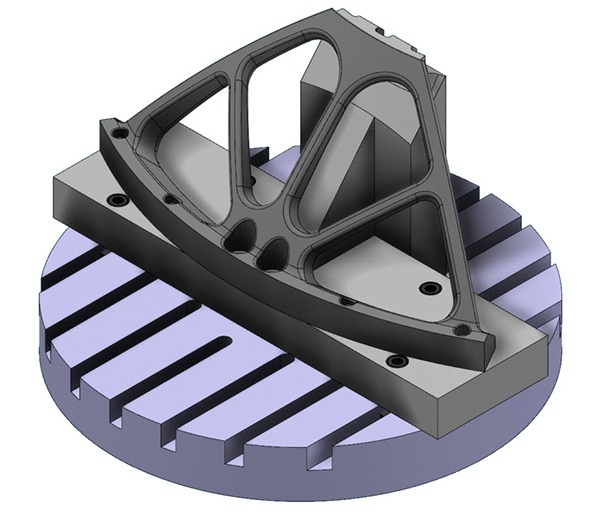

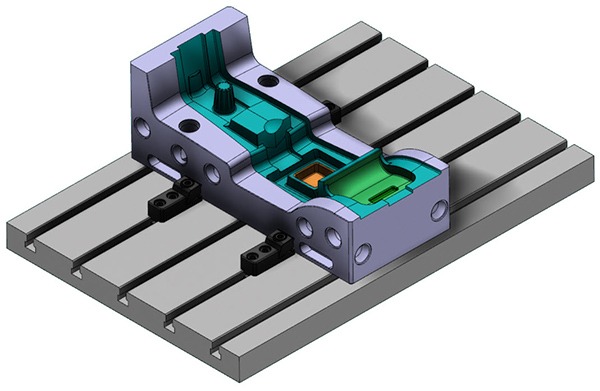

4. Machine Group Setup

With Machine Group Setup (MGS), setting up a job in a CAM system from stock to simulation has never been easier or more organized. MGS introduces the concept of Master Model to Mastercam, an intuitive interface which allows the system to be more aware of what the finished part is for programming and simulation. Components can now be imported and positioned correctly right inside the MGS interface.

5. Supporting Multiple Steady Rests

Confidently control the work holding in your Mill-Turn machine with multiple steady rests. Mastercam’s modular machine definition architecture means that you can organize your steady rests in several different configurations.

6. Equal Scallop Stock Awareness/Step Ins

Equal Scallop is a fully stock aware, semi-finishing toolpath that now identifies material left in corners and will machine with a single pass or with multiple passes to ease into the material. With this new functionality, simply specify a previous roughing tool and a max engagement and Equal Scallop automatically creates iterative and safe step in passes to prep for finish. This functionality essentially turns Equal Scallop into a stock aware, semi-finishing toolpath.

7. Mesh Enhancements

Check Mesh includes a new option in Mastercam 2023 to delete problem facets. Meshes have always been a challenge to machine, but due to advancements in reverse engineering, they are becoming more prevalent. Check Mesh can analyze and fix problem areas to prepare models for programming. Combine this functionality with the other powerful mesh enhancements, and Mastercam is perfectly suited to complement and enhance new additive and reverse engineering technology.

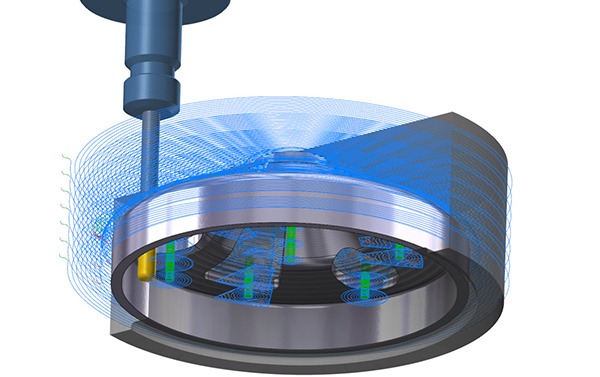

8. More Powerful and Flexible 3D Roughing Linking

Control and optimize your air cuts with the new linking parameters in OptiRough, which allow for greater efficiency in roughing toolpaths when transitioning between passes or when in air. No matter how efficient the roughing program, air cuts make up a significant portion of cycle time and the ability to control and optimize this motion is just as critical as getting feeds and speeds set correctly

9. Grouping Viewsheets

Mastercam 2023 gives you the ability to create viewsheet groups. Use viewsheet groups for better organization, more efficient workflow, and reduced on-screen clutter. To support even the most complex assemblies, users can now categorize views by color and grouping.

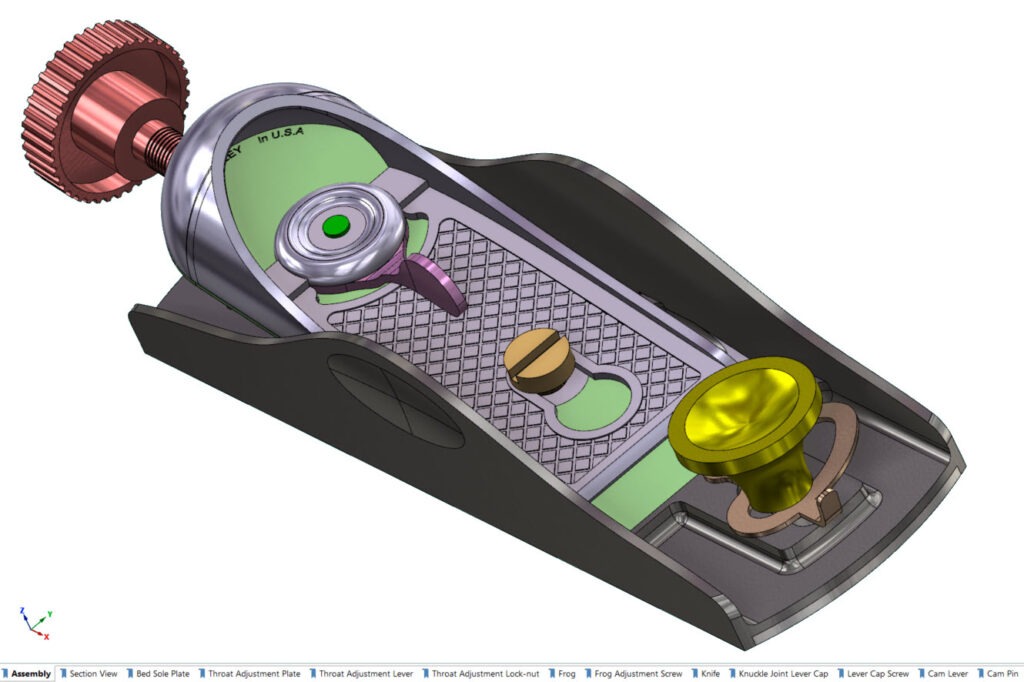

10. Controlling the Tool Contact Point

A win from every angle: Deburr now supports more than just ball endmills. The Deburr toolpath includes a new Fixed tool contact point on cone/cylinder option, which controls the tool’s contact point during machining. This new tool axis feature creates Swarf-like functionality with the selection of just a solid edge. No more custom lollipop tools; you will now find less cost, less cycle time, and easier programming all in Mastercam 2023.

Ready to upgrade?

If seeing the top Mastercam 2023 features has you ready to upgrade or you want to learn more about solutions for more efficient manufacturing, contact a Mastercam Reseller. Our global network of Mastercam Resellers is available to give you localized knowledge, sales, training, and CAD/CAM software support for your manufacturing needs. Complete our form to find your local Mastercam Reseller.