CAD/CAM Software Simplifies Multiaxis Machining of Turbine Blades

FGP Systems Ltd., Weymouth, Dorset, England, offers machining, surface treatment, and assembly capabilities to its customers in the defense and civil aerospace industries. During his 24 years with the company, Simon Griffiths-Hughes, Systems Operations and Engineering Director, has witnessed the exciting evolution of machining capabilities at FGP. That evolution has been driven in part by Mastercam.

Quick Facts:

Product Used: Blade Expert, Multiaxis, Milling

Industry: Aerospace, Defense

Project Details:

- The Challenge: Machining turbine blades and overcoming extensive part programming times.

- The Solution: Mastercam, the most widely used CNC software for machining applications

- Benefits:

- Mastercam Blade Expert provides a comprehensive solution for various blade configurations.

- Blade Expert follows the Mastercam standard used by all multiaxis toolpaths, ensuring a short learning curve and successful deployment.

- The CAD/CAM software helped improve surface finish and part quality and reduce programming time.

“We took the plunge into full 5-axis machining 20 years ago,” said Griffiths-Hughes. “We needed something to compliment the capability of our 5-axis machine. Mastercam was the right package to support our journey.”

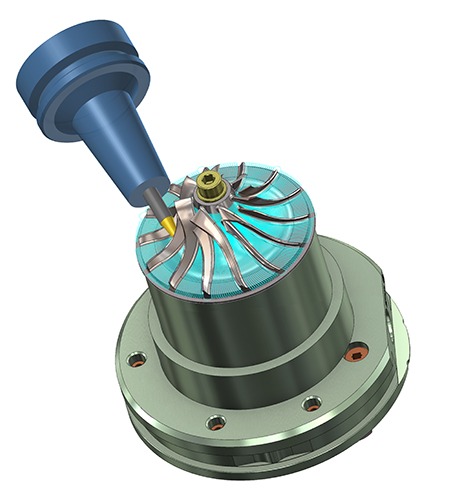

A few years ago, a customer approached the FGP engineering team about machining turbines. The manufacturer agreed to take on the job, but initial part programming time was extensive. The company needed CAD/CAM software that could fully support turbine machining. FGP Systems chose Mastercam Blade Expert, a software interface that provides a comprehensive solution for various blade configurations and follows the Mastercam standard used by all multiaxis toolpaths, ensuring a short learning curve and successful deployment.

“Blade Expert is so intuitive and easy to use that it was an overnight revelation for us,” said Griffiths-Hughes. “It made programming that much easier. It has evolved from that point of every iteration of Mastercam and Blade Expert, and it is customizable.”

FGP Systems manufactures a wide range of turbines, from numerous blade types to scroll turbines. Every scroll-type turbine the company produces contains a splitter or multi-splitters. Before adopting the CAD/CAM add-on feature, working around the splitters proved difficult. The software provided a much-needed solution.

“The machine strategies within Blade Expert are easy to set,” said Griffiths-Hughes. “If we figure out a strategy for a titanium blade, then we can pass that down to our engineers. We tell them that this is the strategy we wish to use on all titanium blades to get the right surface finish, part quality, and return from our Blade Expert investment.”

In addition, integrated CAD for CAM capabilities allow the import of files from virtually any computer-aided design source. Mastercam includes a comprehensive selection of CAD model importers and the suite of tools in Model Prep permits modification of solids.

According to Griffiths-Hughes, once one turbine is manufactured, the turbines that follow tend to be similar; the challenge lies in effectively machining the gap between the blades. The main blade, splitter blade, depth of cut, and machining strategy vary, but Blade Expert provides the ability to bear those toolpath strategies to metal. It controls depth of cut, root radiuses, and stock removal. As the billet form is machined, a stereolithography (STL) file background is created and stock removal is closely monitored.

Once FGP Systems delved into multiaxis machining, the company picked up difficult porting jobs, including a military application.

“I don’t think that the learning curve for multiaxis machining was massive,” said Griffiths-Hughes. “You have to embrace the fact that it’s not just about the CAM package itself—it’s the CAM package, the machine tool, and the post processor. If you get all three elements correctly, it can work for you.”

Embracing multiaxis machining allows FGP Systems to take on challenging parts and expand its customer base, he added. “If we didn’t have the full advantage of the 5-axis machining and the supporting CAD/CAM package, we wouldn’t have been successful.”

Customer Quote

“We needed something to compliment the capability of our 5-axis machine. Mastercam was the right package to support our journey.”

— Simon Griffiths-Hughes, Systems Operations and Engineering Director, FGP Systems, Ltd., Weymouth, Dorset, England