Tech College Alum Teaches CAD/CAM at Alma Mater

Tri-County Technical College teaches Mastercam to prepare students for successful manufacturing careers.

The Challenge

Finding powerful, user-friendly CAD/CAM software that will prepare tech students for future careers.

The Solution

Mastercam, the most widely used CAD/CAM software for machining applications.

Benefits

- Mastercam is user-friendly and widely used within the manufacturing industry, making it a perfect fit for technical school curriculum.

- The new, enhanced G View Cube helps students with spatial recognition.

Project Details

A true testament to an educational institution is the success of its alumni. Returning to one’s alma mater as a faculty or staff member is especially noteworthy. Such is the case with Gerald Maxie.

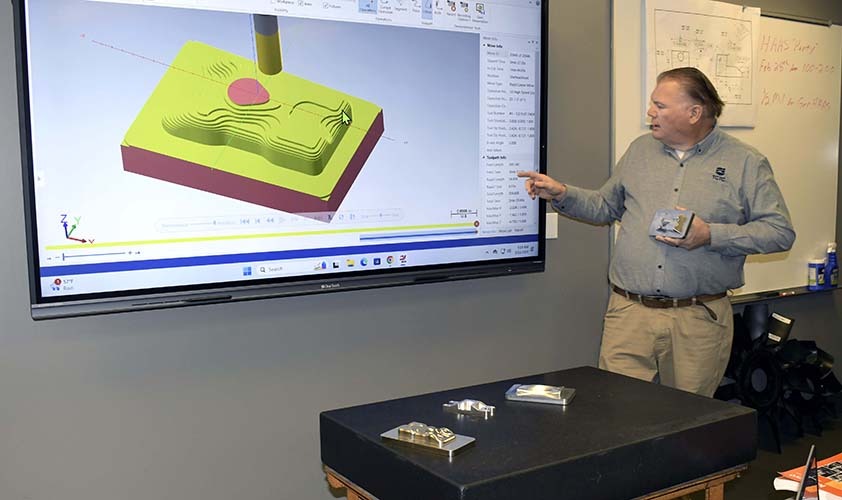

“I graduated from what used to be the Machine Tool Technologies program at Tri-County Tech back in 1993, so I’m a product of the college,” said Gerald Maxie, instructor of CNC Programming and Operations in the Advanced Manufacturing program, Tri-County Technical College, Pendleton, South Carolina. Here, 14 buildings house classrooms, laboratories, and machine shops.

“We’ve been using Mastercam since I can remember,” he said. “In my opinion, it is one of the most user-friendly CAD/CAM software packages on the market. It fits well with our curriculum.”

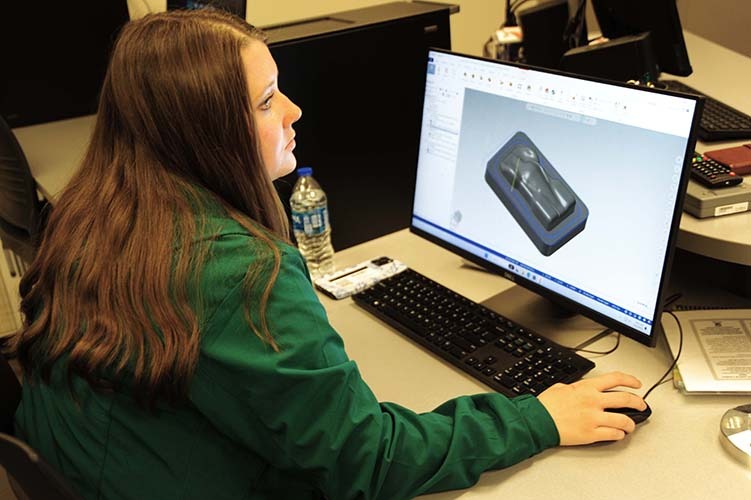

Tri-County Tech offers an associate degree in CNC Programming and certificates. Currently, 45 students are enrolled in the Advanced Manufacturing program. By their fourth and final semester, students are able to produce 2D CAD drawings and complete several CNC machining projects.

Armed with 50 seats of Mastercam, the school’s machining facilities house several manual mills, lathes, and grinders, plus 23 CNC machines, including Haas VF-2s, a VF-4, a 5-axis UNC-750, several ST-20s, a Swiss machine, and fabrication equipment.

“We call it the mothership,” said Maxie of the Pendleton Campus machining facility. Students start off on manual machines and second-year students are introduced to CAD/CAM software. For their class project, each individual must create a woodworker’s vice, which mounts under a table. A set of blueprints is provided for each vice part and students then draw the parts as Mastercam solid models. All work is performed in Mastercam.

“I want them to fully understand every aspect of what the CAD/CAM program can do,” said Maxie.

Students draw each individual part—including a handle and two vice jaws—as a solid and then program the parts. Next, they compile a process sheet and determine fixturing. When selecting toolpaths, they use everything from 2D Dynamic machining to Contour, Drill, and Peel Mill. It takes the class half of a semester to get their parts programmed, machined, and working. The two main stand-up vice jaws are machined from a 4-inch by 6-inch aluminum billet. The middle rod is an ACME screw thread fabricated to fit the part.

In addition to providing in-class instruction, Maxie assigns camInstructor® online software tutorials as supplemental lessons. “I’ll assign them as homework,” he said. “Students can download the home edition. I always say that the only way you’re going to get good at any software program is through set times for working on programming projects.” camInstructor Inc. (Cambridge, ON) offers Mastercam training courses in both online and hybrid formats.

The Advanced Manufacturing program’s fifth semester covers 3D surface programming and revolves around an IndyCar project. Each student receives a skeleton wireframe of a racecar and uses the 3D Dynamic OptiRough toolpath before performing a finishing pass. Maxie encourages his students to experiment with various surface finish toolpaths and determine which one yields the best results. The car is machined from a 4-inch by 8-inch by 2-inch block of aluminum.

“I love the new radial chip thinning that Mastercam added several versions back,” he said. “It allows us to calculate the proper feeds and speeds when we do a smaller stepover.” The feature lets students make deeper cuts and smaller stepovers while increasing the machine’s feed rate, cutting machining time in half when compared to traditional methods. Also, the new enhanced G View Cube will be a great asset for Tri-County students. Maxie predicts that it will help them with spatial recognition.

“I just opened some of the newer features that Mastercam has developed and improved,” he added. “I keep up with the newest release and work with our Mastercam Representative, Barefoot CNC (Morganton, NC) to keep myself current on the latest and greatest features.”

With software version rollouts, training, and troubleshooting, Maxie knows that he can rely on his Mastercam Representative when needed. He has visited Barefoot CNC several times for training and refreshers.

“The team helped me understand Dynamic Motion technology and when to use it. They are just a great resource,” he said.

According to Maxie, 90% of Tri-County Tech’s students land full-time employment before they graduate. Well-trained tech grads are in high demand within the region.

Quick Facts

- Product Used: Educational Suite, Productivity+

- Industry: Education

“We’ve been using Mastercam since I can remember. In my opinion, it is one of the most user-friendly CAD/CAM software packages on the market. It fits well with our curriculum.”

Gerald Maxie, Instructor of CNC Programming and Operations, Advanced Manufacturing Program, Tri-County Technical College, Pendleton, South Carolina