CAM Software Takes the Tension Out of Manufacturing Lead Times

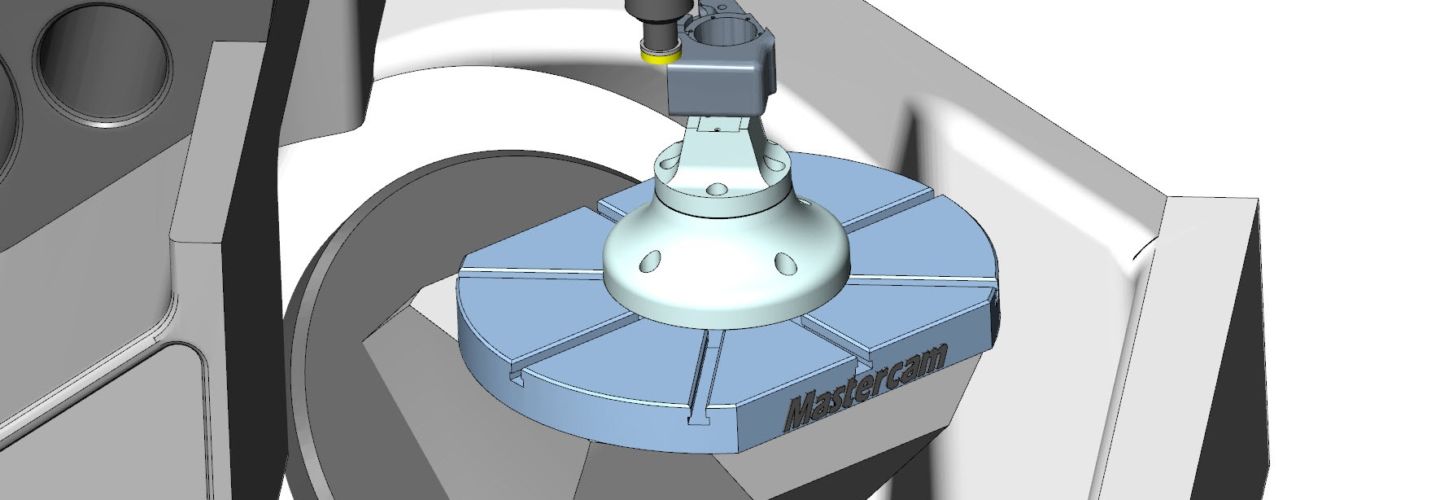

Allstrap, Inc., (Upper Arlington, OH) specializes in the manufacture of the steel and poly straps that hold sizeable loads together, as well as the pneumatic and battery-operated tensioning tools that keep the straps taut. The company has seen an increase in demand for the battery-operated tools which perform cutting, tensioning, and sealing operations 30 to 50 percent faster than their pneumatic counterparts. To meet the need, they combined Mastercam® CAD/CAM software with a 5-axis CNC universal milling machine to significantly reduce production time.

Quick Facts

- Product Used: Mill, Productivity+, Dynamic Motion

- Industry: Transportation

Project Details

- The Challenge: Design and manufacture a light-weight battery-operated strapping tool to meet increasing customer demand. Parts needed to be made faster in order to deliver product to market quickly but without tool and part breakage and costly errors due to inability to view the manufacturing process at high speeds.

- The Solution: Mastercam, the most widely used CNC software for CAD/CAM operations.

- Benefits:

- Easy to learn

- Dynamic toolpaths allow machines to run at very high speeds without tool breakage

- Ability to verify toolpaths, machine speeds, collision potential, and part tolerances prior to machining

- Issues can be detected through probing add-ons to avoid unnecessary shut downs

Allstrap, Inc., (Upper Arlington, OH) specializes in the manufacture of the steel and poly straps that hold sizeable loads together, as well as the pneumatic and battery-operated tensioning tools that keep the straps taut. The company has seen an increase in demand for the battery-operated tools which perform cutting, tensioning, and sealing operations 30 to 50 percent faster than their pneumatic counterparts. To meet the need, they combined Mastercam® CAD/CAM software with a 5-axis CNC universal milling machine to significantly reduce production time.

Tools are made from either aluminum, stainless steel, or 4140 pre-hardened steel and weigh between 6 to 15 lbs. Between 25-100 components comprise each tool. According to president Josh Sikora, once the concept for a tool and its parts are finalized, they will switch to either stainless or 4140 for the end product. Although lighter in weight, machining these stronger, lighter-weight steel materials without tool breakage and other mishaps in a reasonable amount of time, is difficult. In order to optimize a new 5-axis CNC universal milling machine, Allstrap needed to invest in a different CAD/CAM software package with features that would push the machine harder.

Sikora had heard of Mastercam and contacted Kevin Richardson at FASTech, Inc. (Mastercam Representative in Findlay, OH) whose experience with the software made the decision to purchase easy for Sikora. Richardson helped Sikora and his lead programmer Bob Freeman set up the software system and integrate it with the 5-axis machine.

The machine has a 50-hp spindle, 60-position tool changer and runs 600 psi through the tool coolant. “When you’re machining at 18,000 RPM and running all that coolant, you really can’t see what you’re doing so you have to rely on your software to get that code where it needs to be or you’re going to get lost fairly quickly and have problems,” said Freeman. He stressed the importance of the work holding equipment to keep things in place, especially when working with larger, high-performance endmills. Freeman uses a dovetail fixture and the Chick OneLOK workholding vice. “The vice lets us precisely soft jaw a part on the machine table within a thousandth of an inch, which is close enough for the tolerances we’re working with on the back of the part, and it makes the production work simply and accurately.”

Richardson connected Freeman and Sikora with end mill suppliers, one of whom makes a 3/4-inch endmill with serrations and 1 5/8 of flute to cut with. Freeman runs it at 190 inches-per-minute at 12,700 RPMs in 6061 aluminum; he can remove three inches of material in five minutes. “We’re taking half the diameter of the cutter so that’s 3/8 of an inch and we’re cutting it 1.5 inches deep. At 190 inches-per-minute that would be 107 cubic inches-per-minute of material that we’re removing,” he said. “A typical 4.5- x 4.5- x 6-inch block disappears in just a few minutes at those rates.”

High speeds are possible using the software’s Dynamic Motion technology which, through the use of proprietary algorithms programmed into the software, detects changes in the geometries and keeps the tool constantly engaged in the material, reducing air cutting and tool breakage. The toolpath can be programmed in five minutes or less. “It would take an hour or more to program it the old way,” he said. After roughing, finishing routines are tailored to take leftover stock and create 3D geometries simply and easily. Manufacturing time has been reduced from one hour per part to 22 minutes per part.

When the machines are running at such speeds it’s difficult to detect problems. Freeman relies on the software to help prevent problems at the outset. Issues are detected within the machine while running a job using the software’s Productivity+ Add-On, allowing Freeman to program and simulate Allstrap’s Renishaw probe and laser system, performing simple measurements and alignments to verify what is going on inside of the machine.

Time savings are significant – prototyping alone took a week or so with 60 to 70 hours spent on building fixtures, and another couple of days devoted to programming. If something went wrong during machining it could mean two-and-a-half to three weeks to make just one part. Freeman said: “When you run around and check a few other things while performing a job, you find that the software, the machine, the tooling, and the work holding all worked together in harmony to give you what it was that you wanted.”

CUSTOMER QUOTE

“When you have systems that you can really rely on they will create what you need. I am speaking of the code coming out of Mastercam. We can verify it, we can look at our fixtures and our machine in Mastercam, and make sure that we’re not going to hurt anything significant. That allows us to go ahead and take that next step because we don’t have to stand there and watch the machine.”

Bob Freeman, Programmer, Allstrap, Inc.