Electrical Components Manufacturer Takes Charge of Mold Making

Find flexible, powerful CAD/CAM software to produce tools, molds, and patterns for a line of electrical power transformer components.

Quick Facts

- Product Used: Mill, Productivity+, Dynamic Motion

- Industry: Transportation

Project Details

- The Challenge: Find flexible, powerful CAD/CAM software to produce tools, molds, and patterns for a line of electrical power transformer components.

- The Solution: Mastercam, the most widely used CNC software for CAD/CAM operations.

- Benefits:

- Mastercam and specialty tooling help H-J produce more complex molds in a shorter amount of time without a significant increase in labor

- OptiRough toolpath removes large amounts of material quickly via Dynamic milling motion to deliver a fully roughed part safely and quickly

- Dynamic Motion technology boosts machining accuracy and efficiency, allowing H-J to use end mills to achieve desired results

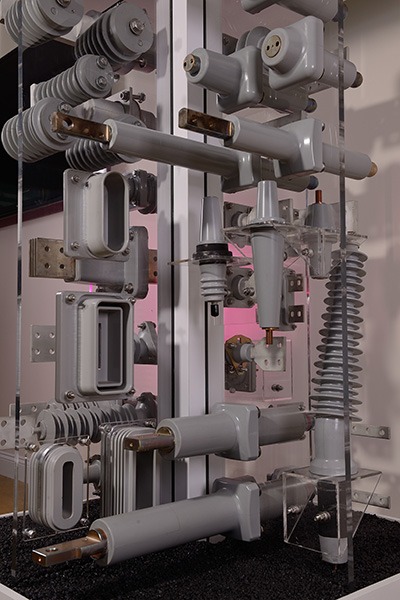

Founded in 1969, The H-J Family of Companies is a global supplier in the transformer, switchgear, and breaker industry. The High Ridge, Missouri-based company is the leading manufacturer of electrical power transformer components in the Americas, operating manufacturing facilities in the U.S., China, and Mexico.

“H-J is a manufacturer and bundler to transformer and switchgear manufacturers,” said Doug Goforth, Manufacturing Support and Improvement Manager at The H-J Family of Companies. “Our products show up on the street anywhere a wire connects to a transformer on the power grid.”

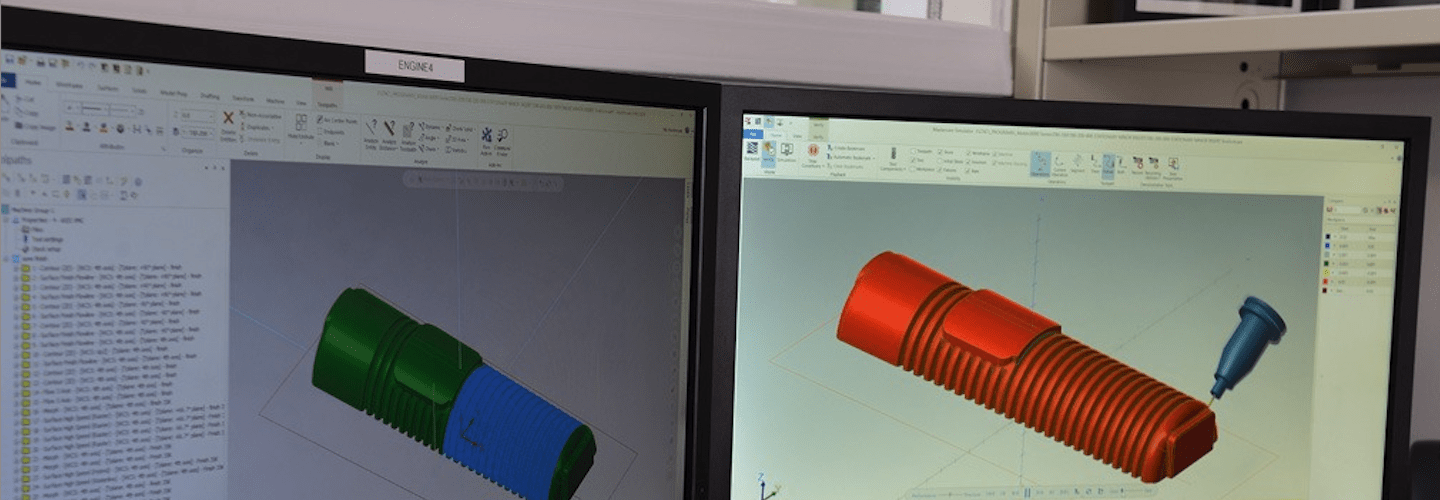

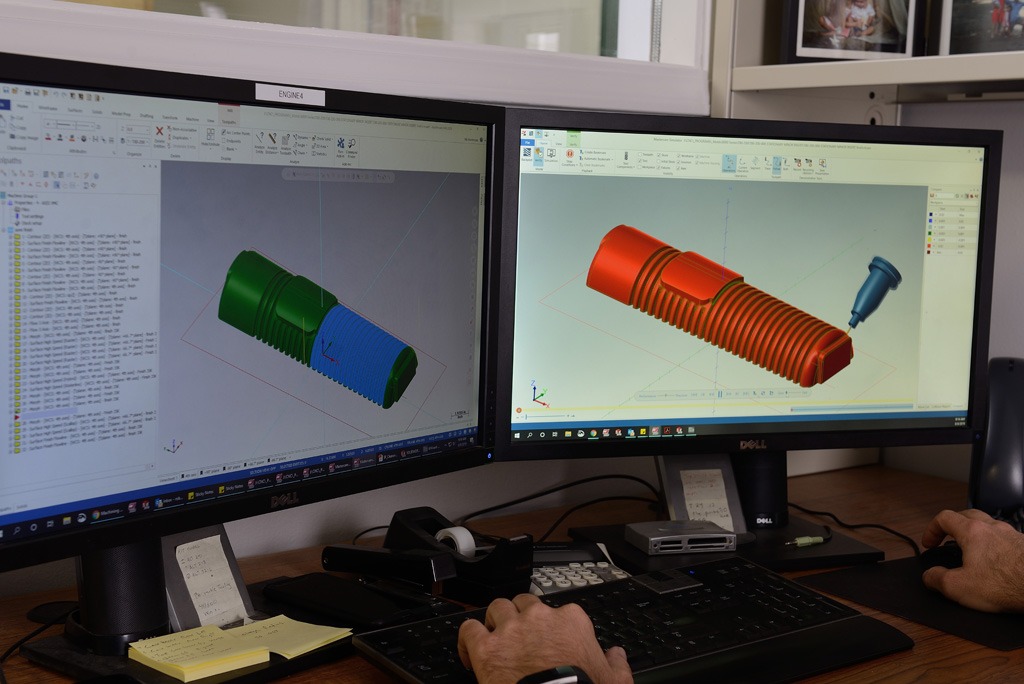

To create an extensive product line that includes bushings, insulators, and custom engineered products, H-J operates as a machine shop, foundry, epoxy resin molder, and more. To produce tools, molds, and patterns for their products, the folks at H-J rely on end mills and CAD/CAM software from Mastercam. The patterns support the foundry operation and metal casting side of the business and the molds are used for epoxy casting. H-J’s four seats of Mastercam support its growing machining staff of 20.

Most of H-J’s parts are produced on vertical machining centers while molds and patterns are predominately milled. At one time, the company produced four molds per year, molds which required extensive hand polishing and finishing. Today—thanks to CAM software and specialty tooling—the company averages one mold per month without a significant labor increase.

“Mastercam definitely helps us optimize our machines and use them the way they’re designed to be used,” said Bobby Schaper, CNC programmer, The H-J Family of Companies. “We do not have to job out molds for specific part profiles that we couldn’t do in the past.”

In November 2018, CNC Software Inc. partnered with Harvey Performance Company and its Harvey Tool and Helical Tool brands of specialty carbide end mills and cutting tools. Toolpaths within Mastercam can now integrate Harvey Tool’s selection of tool options. Harvey is known for specialty profiling and miniature tooling and Helical offers material-specific, high performance end mills. Bringing the power of CAM software closer to cutting tool technology brings increased productivity to H-J’s existing machines.

“We have $200,000 mills that are consistently putting out quality parts normally seen on $500,000 machines,” said Goforth.

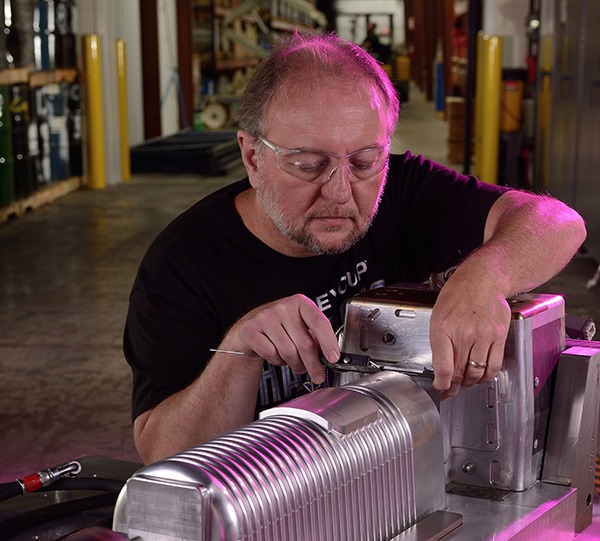

One of those parts is an insulator for a transformer. The shed section, which resembles a stack of small rings, is used to prevent electrical failure in an insulator in cases of air and water contamination. A major challenge in producing sheds is finding the right small-diameter, long-reach tool that does not deflect or chatter during machining. Because the sheds are very thin, H-J uses Harvey specialty tooling called tapered reach (clearance cutters) to produce them. Most of the Harvey end mills selected for the application have specialized tapers for support and small tips, some as small as 0.015″ in diameter.

In addition to specialty tooling, H-J employs Mastercam’s Dynamic Motion toolpaths to boost machining accuracy and efficiency. Before using the toolpaths, programmers used small step-downs and large step-overs with indexable tools. Dynamic Motion technology allows H-J to take a different approach and use end mills to achieve the same results, sometimes faster.

“Dynamic toolpaths are my favorite to use,” said Schaper. “I use them on almost every part, and not necessarily for finishing.”

For roughing sheds, H-J programmers’ toolpath of choice is OptiRough. This bi-directional cutting strategy removes large amounts of material quickly via Dynamic milling motion. Large, aggressive cuts are followed by fast, smaller up-cuts to deliver a fully roughed part safely and quickly. Spindle speeders are used for finishing to increase machine speeds up to 50,000 RPMs.

“I believe the toolpaths and spindle speeds help the miniature Harvey tools achieve what they were designed to do,” said Schaper. “We’d rather put a tool in a situation where it can succeed rather than push it more for the sake of cycle time yields.”

Most parts that H-J manufactures range anywhere from 0.5 to 100 pounds. To accommodate this variety of parts, H-J’s mold making operation requires two shifts to service the entire factory of molding presses that operates on three shifts. Each mold typically has at least two cavities, and in some cases up to six. Fitment tolerances are ±0.002″.

Recently, H-J made a mold for research and development purposes for a hollow-centered part that was 14.5 inches in diameter and 5 feet tall. Each aluminum mold half weighed 1,400 pounds. Due to its size, the mold was divided into four pieces per section and had two parting lines. The configuration allowed a 45-degree rotation of the block to minimize tool reach to the bottom of the shed. With no 5-axis machine available at the time, H-J machinists performed 3-axis machining, reaching five inches deep using 0.25-inch-diameter end mills, to complete the job.

The most daunting aspect of this 3-axis machining operation was locating each block in the machine because a flat surface did not exist once the part was tilted. Toolpaths used to complete the process were Dynamic Mill, OptiRest, OptiRough, then Flowline for finishing. With the help of Dynamic toolpaths, specialized tooling, and vendor support, the mold was produced in three weeks. The final part weighed 230 pounds.

“We had six weeks to pull off the part design, product design, mold manufacturing, and part production in order to get the part to a trade show,” said Goforth. “We’re making molds in 8 to 12 weeks, which sets us apart from a lot of mold shops and product manufacturers. We can now take and produce custom products, complete with tooling, in weeks as opposed to the better part of a year.”

For the H-J Family of Companies, the benefits of CAM software, precision tooling, and customer support cannot be overstated.

CUSTOMER QUOTE

“We’re making molds in 8 to 12 weeks, which sets us apart from a lot of mold shops and product manufacturers. We can now take and produce custom products, complete with tooling, in weeks as opposed to the better part of a year.”

Doug Goforth, Manufacturing Support and Improvement Manager, The H-J Family of Companies, High Ridge, Missouri