School Career Tech Program Reaches Grade K-12

Manufacturing careers might have been an afterthought when a career manufacturing professional began a new venture as a teacher. Now, Mastercam has aided an entire school district in its march toward a manufacturing future.

Quick Facts:

Product Used: Educational Suite

Industry: Education, Metalworking, Woodworking, Architectural Millwork

Project Details:

- The Challenge: Providing school-aged children and adolescents with an opportunity to learn about modern manufacturing technology.

- The Solution: Mastercam, the most widely used CNC software for CAD/CAM operations.

- Benefits:

- Mastercam is intuitive enough for even young students.

- Students may “skip over” obsolete manual processes.

- In a focused program, many projects can be run simultaneously.

During his 15 years in industry, Matt Arnos wore many hats. He went from sweeping shop floors to machining, engineering, fabricating, and running CNC machines. He painted, assembled, and wired his way into the role of installer. He traveled the United States, installing manufacturing equipment and teaching others how to operate the machines.

“The part I enjoyed most of all was training the operators,” said Arnos, Stryker Local School District Career Tech Education (CTE) instructor and FFA advisor. “That was something that I looked forward to.”

His enthusiasm for teaching others has served Arnos well, both on the shop floor and in the classroom.

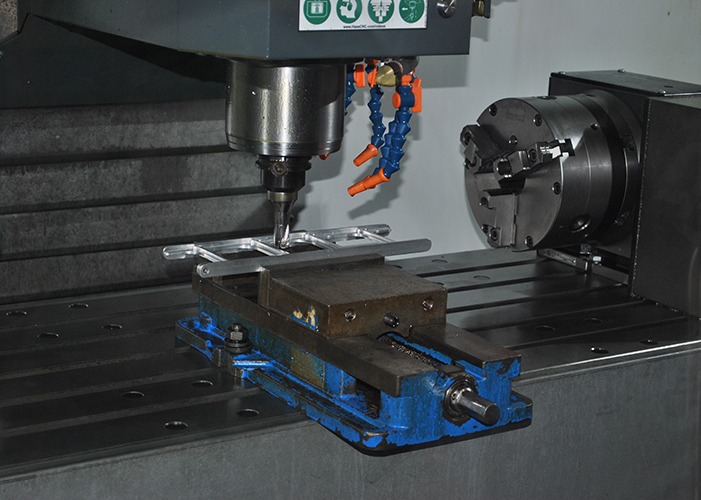

Stryker’s CNC shop is home to a CNC vertical mill, lathe, wood router, a plasma cutting table, and 17 computer stations that run Mastercam CAD/CAM software. The Stryker district starts the high schoolers’ tech trajectory in eighth grade, with an introductory approach to CNC. Arnos’s laptop is connected to a Clevertouch interactive display; students watch the process of CNC programming, then see how parts are run. With younger students, if one seems particularly interested in a program or part, Arnos will have that student load the program and run the part.

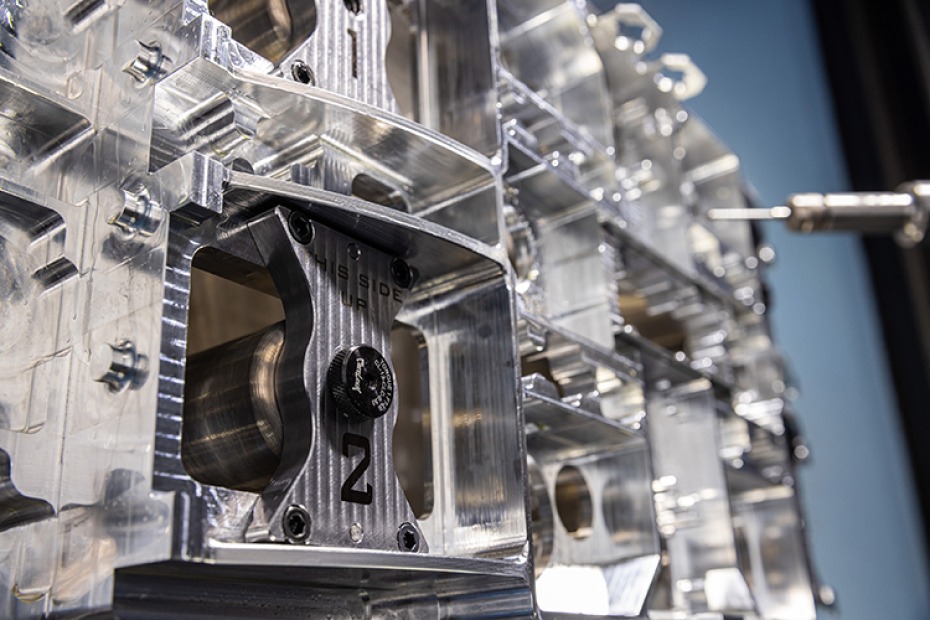

By the time they are juniors and seniors, students are exposed to the school’s Capstone class. It is more focused, and programming is at the forefront. A class of 15 students sometimes has 15 projects going on at once. Arnos estimates that, in the previous school year, students completed more than one thousand projects.

Today’s manufacturing strategies are in many ways different from what Arnos learned during his years in machine shops. Stryker High School’s mascot is the panther, so machined panther paws are a popular pursuit in the tech program. But even crafting panther paws is not what it was just a few years ago, thanks to updated technology.

When Arnos first piloted the tech program at the high school, he was filling a void. It had been eight years since the school had any semblance of a program geared toward manufacturing. That is not the case now. In addition, Stryker Schools’ strategic partnerships with local organizations have helped enrich the program. According to Arnos, 82 companies across the world support the Stryker program.

Stryker Schools, with the support of the community and Arnos’s leadership, now offer a tech program for students in grades K – 12.

“So, kindergarteners are physically starting the milling machine and watching it run, all based off the color of the keys.”

Arnos considers it inevitable that there will be a day when more students arrive in his classroom with additional experience, skills, and interest than his former and current eighth-graders.

“I’ve been blown away as some of the academic teachers have started picking up on different things the students do with the software and helping them with their projects,” Arnos said.

Customer Quote

“So, kindergarteners are physically starting the milling machine and watching it run, all based off the color of the keys.”

— Matt Arnos, Career Tech Education (CTE) instructor and FFA advisor, Stryker Local School District, Stryker, OH