FK Instrument Co. specializes in manufacturing aerospace parts with exceptionally tight tolerances. To maintain profit margins, FKI must be able to produce these precision parts quickly and accurately.

The Challenge

Manufacturing exceptional, ultra-critical tolerance aerospace parts within a tight timeframe.

The Solution

Mastercam, the most robust CAD/CAM software for machining applications.

Benefits

- Network of knowledgeable, experienced Mastercam Representatives who can introduce and explain new techniques and functions.

- Unified Multiaxis toolpath, where Morph, Parallel, Along Curve, and Project Curve commands are all easily accessed in one location.

- Fully customizable Tool Library organizes all relevant data on cutting tools and toolholders.

- Stock-aware Dynamic Motion toolpaths that optimize cutting and safeguard materials and tools.

Project Details

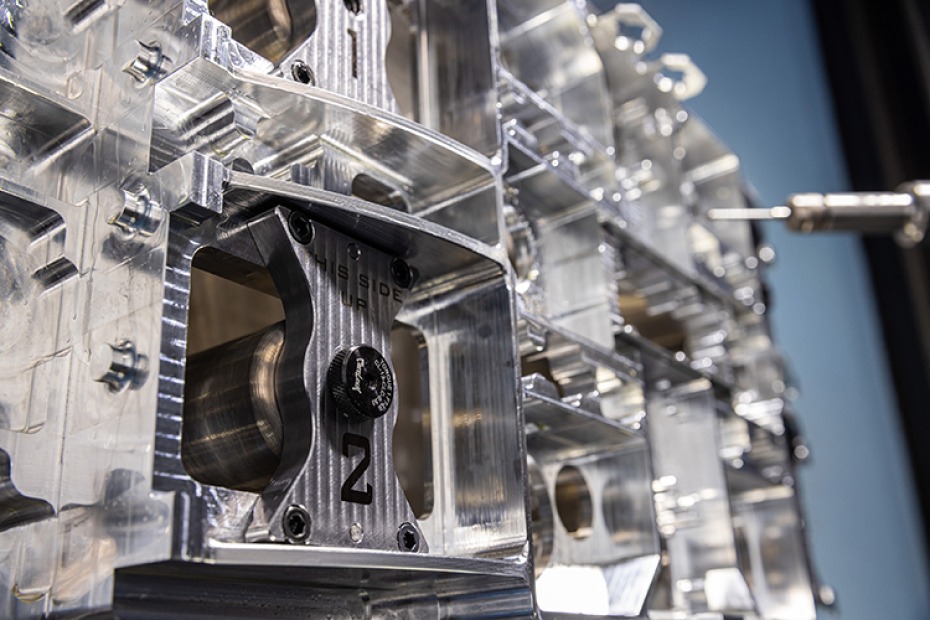

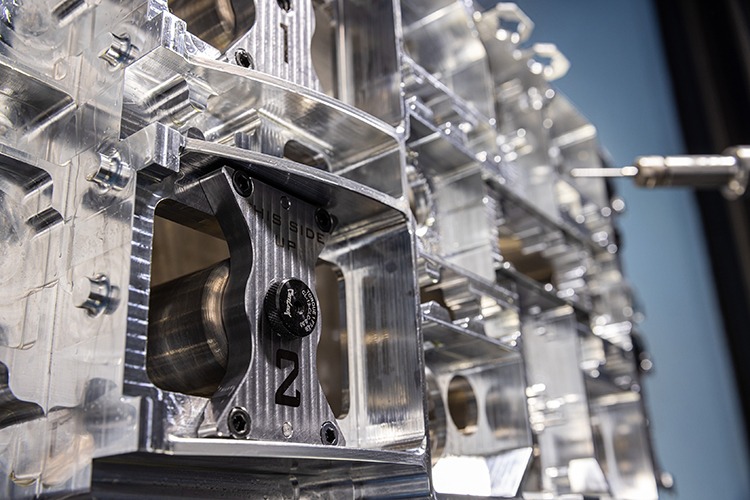

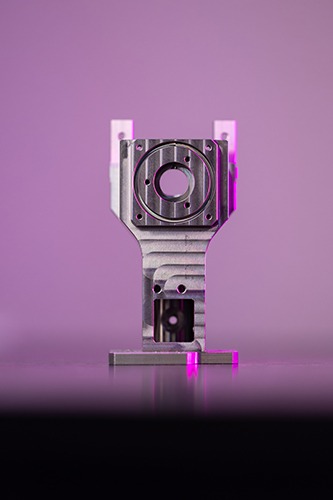

FK Instrument Co., Clearwater, FL, is an internationally renowned aerospace manufacturer that has been using multiaxis machining for approximately 15 years. All of the CNC mill, wire, lathe, and multiaxis units in FKI’s shop are powered by Mastercam. FKI’s certified Mastercam Representative, Camtech Engineering Services (Port Orange, FL), keeps both FKI’s CAM suite and programming team up-to-date. The newest addition is a Yasda YBM 8T-TT. The high-speed trunnion-style 5-axis horizontal machining center delivers simultaneous 5-axis conical machining circularity tolerance of 2.8µm. The machine is paired with a Fastems 18-pallet automation system.

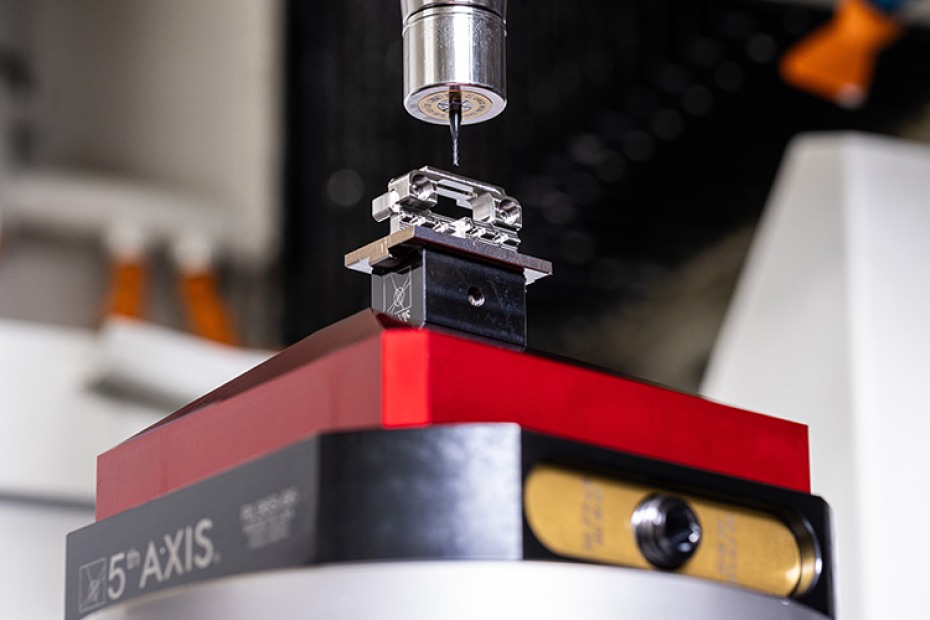

The overwhelming majority of FKI’s parts are what Jeremy Fritchy, manufacturing engineer, refers to as “ultra-critical” tolerance parts—parts with incredibly tight tolerances that couldn’t be achieved anywhere but in the most advanced multiaxis shops. “Because of the size and tolerances of the parts, we were limited on tooling,” said Fritchy. Fortunately, his software’s Dynamic toolpaths made it possible to use very small endmills.

Dynamic Motion technology, unique to Mastercam, does not simply map out the material to be cut; it also analyzes the machining process continually during cutting. As material warps or chip size begins to waver, Dynamic automatically adjusts angles, feeds, and speeds to maintain optimized cutting. One of the advantages that FKI most often relies on is Dynamic’s ability to minimize stepovers and engage the entire flute length of the cutting tool. This allows for better heat distribution and uniform tool wear.

Dynamic toolpaths optimize cutting during machining. Fritchy often uses Dynamic OptiRough with 3D High Speed Raster, a roughing approach powered by Dynamic Motion technology’s characteristic deep step-downs and stock-awareness. Its ability to account for any random material fluctuations is critical when machining frangible or difficult metals, as FKI often does. Since employing OptiRough, Fritchy has noticed consistent chip load, reduced vibration, and faster speeds. He said, “It allows us to use higher feeds and speeds on the high-temperature, low-torque alloys we cut.”

Cutting back cycle time is especially advantageous when running high-priority parts. The updated interface keeps all machine settings and definitions under one tab for ease of access.

He likes to keep track of his tooling, fixtures, and machine data in the software’s fully customizable Tool Library. The FKI team members manually input all of the information for their custom-made tooling and toolholders into the program, but they can also download the tool libraries of outside manufacturers when they need to outsource tooling manufacturing. As they record this information, they can annotate each with their own thoughts. Fritchy also records the feeds and speeds for different materials and machines in his library. “We all share a library and every one of us can see which tools are in which machine,” he said. The data is critical to working as a team, particularly with cutting-edge machines that each have identical stage tooling.

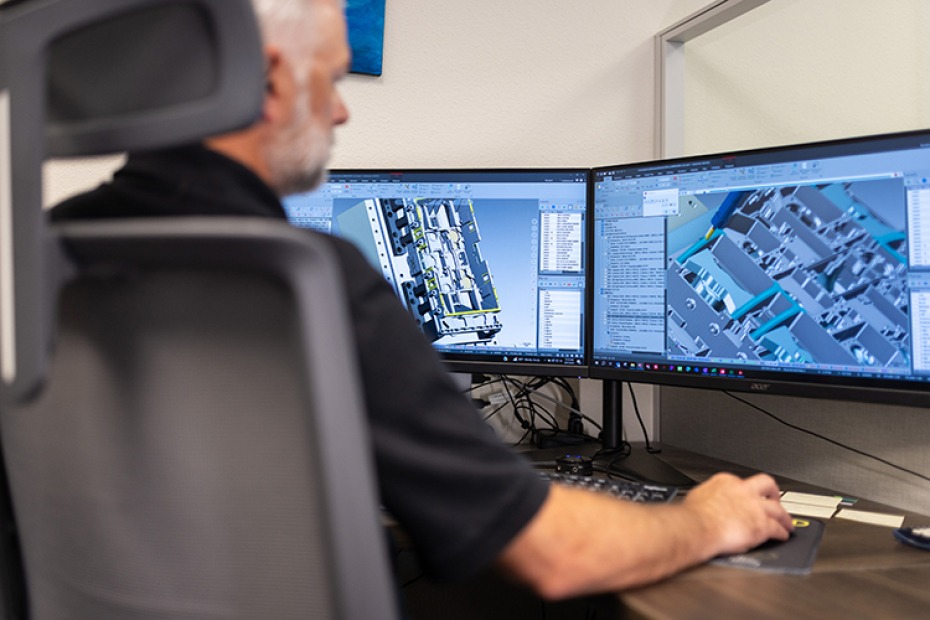

After toolpath programming is complete, Fritchy checks his work. His CAD/CAM package comes equipped with powerful in-system simulation, but it is also readily paired with specialized, precise third-party verification add-ons. Fritchy often relies solely on the in-system Verify, Backplot, and Simulation tools. “It’s the easiest way for us to verify that our toolpaths are achieving what we are looking for,” he said. The functions check for possible collisions, gouges, air cuts, and programming mistakes. If found, these issues are immediately brought to the attention of the programmer for fixing.

Quick Facts

- Product Used: Multiaxis, Mill 3D, Lathe, Wire

- Industry: Aerospace

Customer Quote:

“Dynamic OptiRough allows us to use higher feeds and speeds on the high-temperature, low-torque alloys we cut.”

Jeremy Fritchy, Manufacturing Engineer at FKI

“Without those advanced toolpaths in the software, I don’t think a lot of these parts would even be possible. Just being able to use previous cuts as stock for continuing tools allows better control of your toolpaths.”

Jeremy Fritchy, Manufacturing Engineer at FKI