Where the Rubber Meets the Road

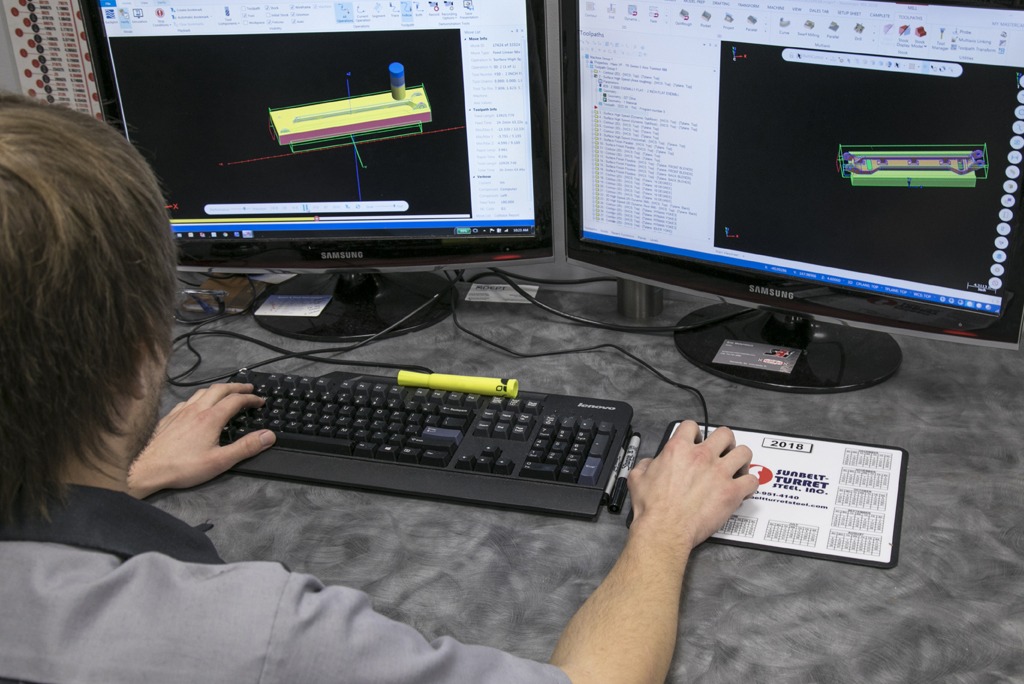

Stewart-Haas Racing is the mechanical support behind multiple winning NASCAR teams. As the company continues to grow, so does its manufacturing workload. The machining team at Stewart-Haas recently began producing more parts in-house, preferring to take advantage of its own abilities. The additional machining was made possible through a combination of an experienced workforce, powerful CNC machines, and intuitive software.

Quick Facts:

Product Used: Mill, Lathe, Dynamic Motion

Industry: Transportation

PROJECT DETAILS

- The Challenge: Profitably manufacture complex, previously-outsourced automotive racing components to save time and money while keeping quality superb.

- The Solution: Mastercam, the most widely used CNC software for CAD/CAM operations.

- Benefits:

- Dynamic Motion technology makes extreme cutting rates possible while saving material and prolonging tool life.

- Pairs flawlessly with a wide range of CNC machines.

- Continuously improving toolpaths are easy to learn and highly adaptable.

Gene Haas, the founder of the CNC tool manufacturing powerhouse Haas Automation, was no stranger to the racing industry when he formed his first NASCAR Cup Series team in 2002. A competitor himself in CART, INDYCAR, Formula One, and NASCAR, Haas let his passion for engineering fuel his passion for racing. He quickly found a partner in Tony Stewart, three-time Monster Energy NASCAR Cup Series Champion, and together, in 2009, they cofounded Stewart-Haas Racing in Kannapolis, North Carolina.

The 200,000 square foot Stewart-Haas Kannapolis facility employs approximately 370 people, all dedicated to building faster, more efficient racecars. John Simmons is the manager of the 4,000 square foot machine shop. It is no surprise that the shop’s equipment is overwhelmingly Haas machines, products of Haas Automation. Stewart-Haas Racing has put even more miles on its fifteen CNC machines lately in an effort to start manufacturing additional parts in-house.

The machine shop recently brought in new Haas turning centers with live milling heads, as the lion’s share of its previously outsourced work had been turned parts. The internal production of these parts means more customizability, faster design to machining times, better quality control, and reduced delivery times. The machining team paired the new Haas machines with Mastercam for reliable, efficient milling.

“The biggest transformation I’ve seen in the last year in our shop is the full adoption of Mastercam’s Dynamic toolpaths,” said Simmons, whose team uses the software’s Dynamic Motion technology to achieve the speed and precision needed to profitably manufacture the new parts. Dynamic milling toolpaths use smoother, safer cutting motions than traditional means. The key is in the software’s constant monitoring of the material being cut. As the parent material changes, the technology assesses, interprets, and extrapolates the fluctuations so that the tool is constantly engaged in the safest way. The calculations are instantaneous. Not only do cutting times melt away, but tool life also lengthens as fewer milling mistakes are made.

Simmons uses a Stewart-Haas steering center link as an example of one of these new parts. The component, which connects the steering gearbox to the pitman arms—and ultimately the wheels—is what allows the vehicle to turn along with the steering wheel. The steering center link begins as a 150 pound, solid bar of alloy steel, around 4 inches wide by 5 inches high by 23.5 inches long before it is roughed out on a Haas VF6 TR 50-taper vertical CNC milling machine. The roughing process for this part, Simmons explained, had taken around twelve hours in the past. Now the roughing takes only seven. “I would say we are 60-75% more efficient,” he said.

Simmons doesn’t overlook the quality assurance that comes with Dynamic Motion strategies, either. Stewart-Haas takes reliability and precision seriously, with a fully equipped quality control department ready to evaluate each and every part for imperfections. Dynamic milling provides a high degree of exactness and repeatability to every cut. The ongoing dialogue between the software and the material means that mistakes are stopped before they even happen, and parts are machined with clinical accuracy.

The team at Stewart-Haas refuses to take all the credit for the application of the software, though. “As the complex technology becomes more pervasive in our shop, the support we receive from our various suppliers is of paramount importance,” explained Simmons. “It’s more than just having the technology; we want to ensure that we are getting the most out of our investments, to ultimately save money, improve efficiencies, and make competitive vehicles. For example, the evolution to the Dynamic Motion toolpaths, while worth it for the benefits, can be tricky to navigate. The light went on much quicker with the assistance of Mastercam’s applications engineers and their Reseller in my area, Barefoot CNC.”

Mastercam’s extensive network of knowledgeable Resellers is a valuable asset to any machine shop, and Stewart-Haas Racing is no exception. Simmons admitted that even with his fifteen years of machining experience, he found the help of Barefoot CNC’s representatives to be crucial in his own learning.

As Stewart-Haas’s machine shop takes on more and more manufacturing, it shows no sign of slowing down. It’s true in both the racing and machining worlds that someone always has to come in last, but it won’t be Stewart-Haas Racing.

Customer Quote

“We can make complete parts straight from a large billet now, rather than having to do smaller components and welding them together. The Dynamic toolpaths give us a lot more tool engagement, which cuts down on us having to optimize the roughing toolpaths and allows us to get to the finish operations much faster.”

-John Simmons, CNC Machine Shop Manager at Stewart-Haas Racing, Kannapolis, North Carolina