Professor LaFrancis Helps Students Get Hooked on Manufacturing

Much of the struggle in recruiting young people to the manufacturing workforce lies in getting students’ attention. Professor John LaFrancis uses a combination of customizable and creative projects to introduce middle school and high school students to the power and potential of manufacturing. It all takes place in machining summer camp at Springfield Technical Community College in Springfield, Massachusetts.

Quick Facts

- Product Used: Mill, Lathe

- Industry: Education

Project Details

- The Challenge: Introducing teenagers to the advanced tools and techniques they will use in a manufacturing career without losing their attention.

- The Solution: Summer camp experience in the STCC manufacturing lab using Mastercam.

- Benefits:

- Watching CNC machines programmed with Mastercam

- Ability to personalize projects

- Intuitive interface that can be simplified for novice users

- Complete CAD/CAM functionality for creative design and machining strategies

Professor John LaFrancis is the Department Chair of the Mechanical Engineering Technology program at Springfield Technical Community College. He runs an annual two-week summer camp for middle school and high school students interested in manufacturing. “The goal is to expose young individuals to manufacturing in the hopes they will continue their education after high school at STCC. We’re trying to introduce the students to manufacturing opportunities through the use of design and manufacturing and some inspection as well,” he said.

The school’s Mechanical Engineering Technology program is an original program of the school. Its graduates have been helping manufacturers with employment needs for more than 50 years. The manufacturing lab was remodeled in 2013. This included an upgrade of 15 new Haas mills and lathes along with many seats of Mastercam for the three computer labs used in the program.

“In our geographic location, this software is the predominant package that is used,” said Professor LaFrancis. “We made the decision probably eight years ago to switch to Mastercam because we wanted students to have the current technology when they leave the institution and go off to the world of work.”

Students are invited to attend classes in the STCC manufacturing lab and to watch demonstrations on its five rapid additive machines, eight Haas lathes (three with live tooling capabilities and a bar feeder), and seven Haas mills (three of which are 5-axis capable). While the students are there, Professor LaFrancis does his best to keep them interested and excited about opportunities in manufacturing for their futures.

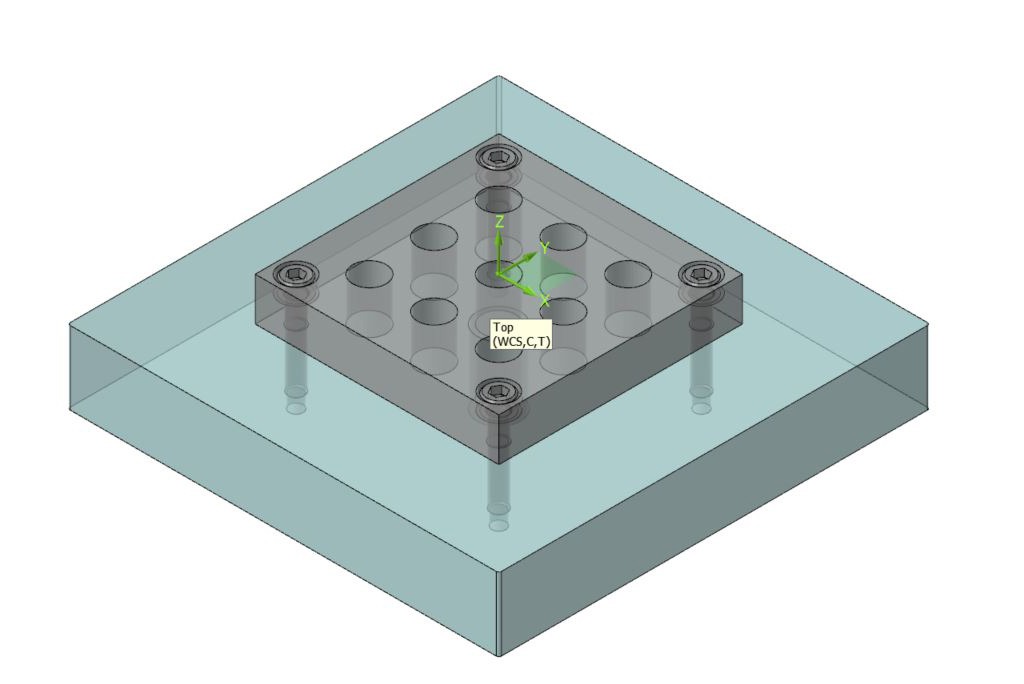

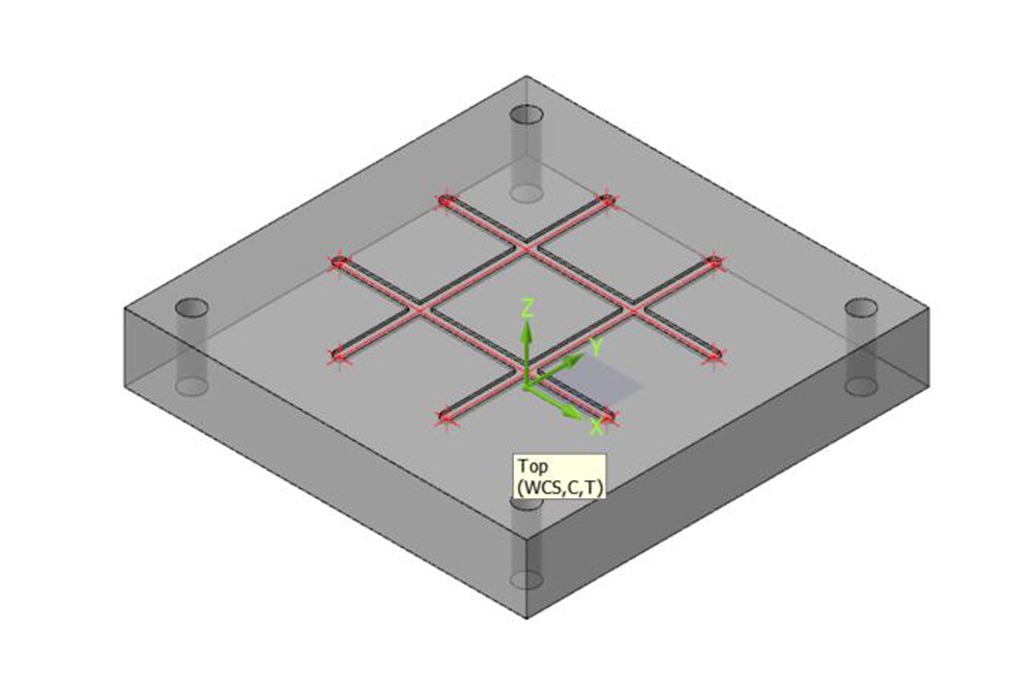

“I think it’s important that they see assemblies,” he said, “and that they see how things can fit together from the start. If they don’t, you have to modify it to fit together when you could have just made them perfectly.” One project he recalls from previous years was a tic-tac-toe board. The top was made from Lexan, the bottom, and playing pins from aluminum.

The pins were made with live tooling, engraving an “X” on one end and an “O” on the other. “They drill holes in the Lexan and they counter-bore holes for the screws. Once they face mill both sides, they attach a cap. The discussion is: how do you tap a hole and which size drill do you need for tapping?” Professor LaFrancis encourages his students to ask questions, suggest creative solutions, and try things they’ve never tried before. Once he sees that the project becomes a game for them, he knows he has his students hooked.

He’s also learned that any project that the students can personalize will be a hit. “We’ve done brass name tags where they can modify the text to be what they want. They’re the West Springfield Terriers, so one student took the image of a terrier and engraved it on the tag. They were free to put what they wanted on three lines of text. They had to size using SOLIDWORKS with a design package, and figure out where to place that text and how to bring those images in. We used Mastercam to create the code and create the finished product.”

According to Professor LaFrancis, Mastercam gives him the opportunity to teach his students time-saving tricks that can’t be found on other platforms. “We can’t just teach them how to make a good product. We have to ask, What is the most efficient roughing toolpath we could use on the milling side? How can we get the best cycle time?, because it’s all about money out there.”

Though Professor LaFrancis works hard to produce the best graduates possible who will help their companies meet that bottom line, his focus is not solely on teaching hard skills. Success to Professor LaFrancis is defined as sparking an interest in a student that might not have ever considered manufacturing and helping them navigate through their early training. He loves seeing the same students who attend his summer school show up to the Mechanical Engineering Technology program for their certificates or associate’s degrees.

Customer Quote

“In our geographic location, this software is the predominant package that is used. We made the decision eight years ago to switch to Mastercam, because we wanted students to have the current technology when they leave the institution and go off to the world of work.”

—Professor John LaFrancis, Department Chair of the Mechanical Engineering Technology Program at STCC, Springfield, Massachusetts