Students Gain Mastercam Skills for Lifelong Careers

Machine Tool Technology instructor Garrett Brown is dedicated to preparing his students for anything they may face in their future careers. He teaches them Mastercam, not only because it is the most widely used CAD/CAM software in his area, but because its intuitive interface and network of support make learning easy for his students.

Quick Facts

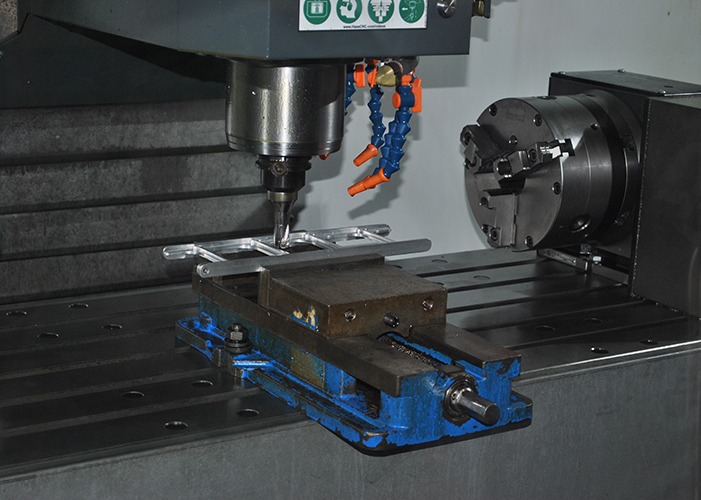

- Product Used: Mastercam Educational Suite, Mill, Multiaxis, Lathe

- Industry: Education

Project Details

- The Challenge: Teaching students a CAD/CAM software powerful enough for them to use in their future careers without overwhelming them with complicated features or interfaces.

- The Solution: Mastercam Mill, Mastercam Multiaxis, Mastercam Lathe

- Benefits:

- Easy to learn and use.

- Resources like camInstructor make teaching the software simple.

- Technical support from authorized Resellers.

- Simulation models the machining process and shows students possible mistakes.

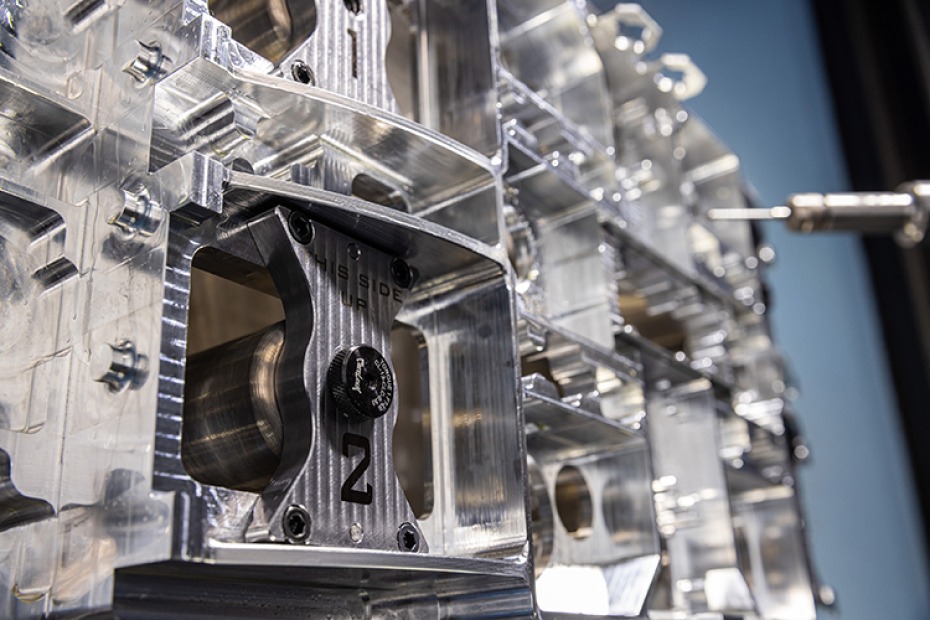

Program Director Garrett Brown said that choosing Mastercam for Spartanburg Community College’s Machine Technology Program was extremely easy. “It’s fairly user-friendly as compared to other software that I’ve used, and it’s very powerful especially when you start getting into the multiaxis toolpaths.”

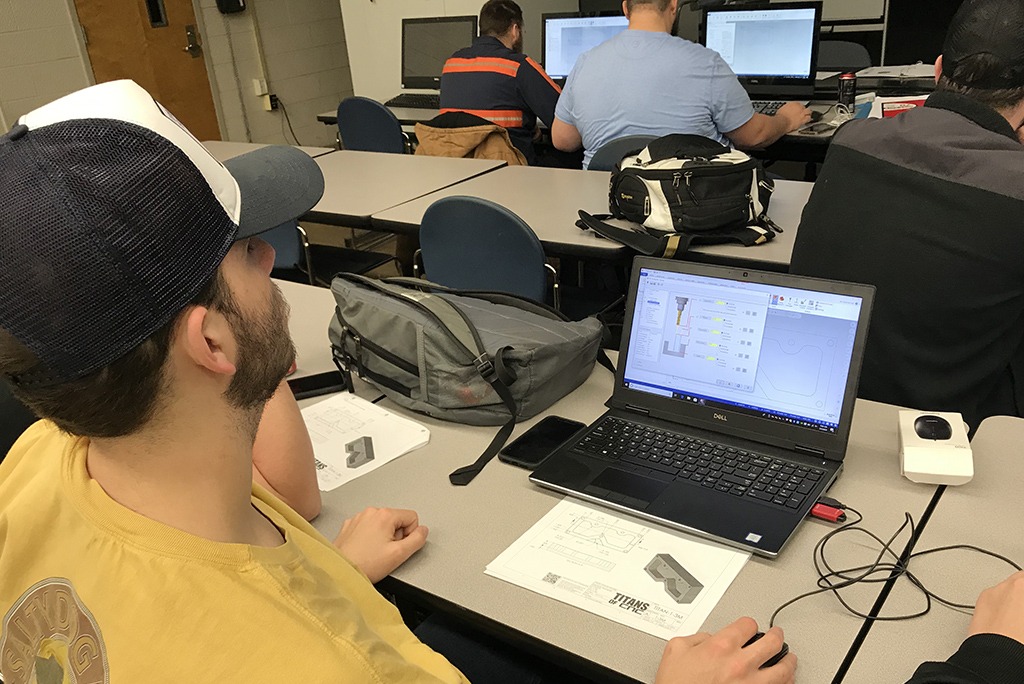

Introducing students to an interface that is both simple enough to figure out and powerful enough to grow with students’ abilities is crucial. “It’s something that’s very familiar to students, because it looks like the Microsoft suite. There’s a ribbon at the top with Wireframe, Solids, and Toolpaths. You can just click on each individual tab and find all the buttons related to that subject.” The software is so intuitive that fellow instructor Shane Wood was able to teach himself how to use it.

That isn’t to say that Wood and Brown are completely on their own to figure the software out, though. Mastercam Educational Reseller, Learning Labs, provided training when they installed Spartanburg’s seats of Mastercam.

Mastercam Industrial Reseller, Barefoot CNC, provides continued support. “Barefoot CNC serves on our advisory board, a committee that meets twice a year. They come to give input on what’s going on in the CNC world,” said Brown. “They also offer training sessions if we need help in a particular subject. And, they’re always there to help us with any kind of troubleshooting.”

With a solid support system behind them, Brown and Wood are free to focus all their energy on teaching. “We try to choose projects that we have decided to have practical applications in a factory,” said Brown. “That’s why we use camInstructor.”

The camInstructor training program has offered online courses, textbooks, and video tutorials since 2007 for CNC programming and Mastercam. The curriculum, which is tailored to fit any school or organization and any student’s skill level, provides a series of projects that teach new techniques as students progress while reinforcing previously learned skills.

Each student in the Machine Tool program receives their own instruction book to follow along with Brown. Students can watch Brown’s screen on an overhead projector and enter the same parameters that he does.

“We go through every toolpath and then run Verify. It’s very helpful to the class if I make a mistake, as bad as that sounds because then the students can see how it shows up on the simulation. We can use it as an opportunity to explain how to fix it and then run Verify again to show that it’s been fixed.” The Verify function highlights possible collisions in a graphic simulation so that programmers can easily check their toolpaths.

Reseller Quote

“We previously had software that was not as good as Mastercam, not as user-friendly, harder to understand, harder to make things move. Our Reseller, Barefoot CNC, helped me with posts, showed me some things, and gave the support it takes to bring us to a whole new level of efficiency.”

—Shane Wood, Instructor, Spartanburg Community College’s Machine Tool Technology Program