Marcel Jordan Creates Works of Art with Mastercam

In a studio on the lower floor of a two-story house and a detached shop in Guelph, Ontario, Canada, Marcel Jordan spends countless hours creating art—and getting attention for it—armed with a router with Z-axis and his CAD/CAM software of choice, Mastercam. The combination has been good for business.

Quick Facts:

- Product Used: Mastercam Router

- Industry: Woodworking, Job Shop

Project Details:

- The Challenge: Jordan was asked to cut the buck for a full-size 1967 Alfa Romeo 33 Stradale Model Car for an internationally known fabrication and classic car restoration firm.

- The Solution: Design and manufacturing software from Mastercam.

- Benefits:

- Geometric nesting feature to keep 277 part numbers uniform and organized

- Selection of toolpath options and tab parameters to help estimate materials costs and time

- Capable assistance from a local Mastercam Reseller

By far, the most challenging project for artist/machinist Marcel Jordan to date was cutting the buck for a full-size model car. The job came from Guelph, Ontario-based Vintage Tin, an internationally known fabrication and classic car restoration firm. Owner Wesley Barbour had built other classic cars, but this 1967 Alfa Romeo 33 Stradale was considered one of the most beautiful and rare cars ever made by Alfa Romeo. Jordan’s job was to make the framework for the car using a design provided by Trevor Lichty of ACL Designs, a reverse-engineering firm located in Fergus. Lichty converted his 3D design to 2D shapes for Jordan, keeping in mind the 3/4-inch plywood being cut for the parts.

The real challenge, according to Jordan, wasn’t cutting the buck but keeping its 250+ pieces organized. He reached out to his local Mastercam Reseller in Canada, In-House Solutions, for help.

“Glenn Bouman showed me nesting, new toolpath options, and tab parameters, something I knew almost nothing about. It was helpful not only in estimating materials costs and machine time, but in getting and keeping so many parts organized.”

Jordan was challenged with the task of machining 90-degree inside slots where the pieces of the buck met. “With 0.0290-inch diameter clearance already designed in the corners, we altered the clearance diameters to 0.43-inches so we could cut the buck with a 0.375-inch endmill,” explained Jordan.

Drilling was concerning because it would add one more operation to the project and, thus, more time. A nervous Jordan called Bouman who suggested changing the geometry of just the corners by programming clearance fillet toolpaths that would create a larger clearance radius in one pass without altering the car’s overall design. Opting to program standard contour toolpaths using a 3/8-inch endmill, Jordan experimented with different speeds and feeds on the machine.

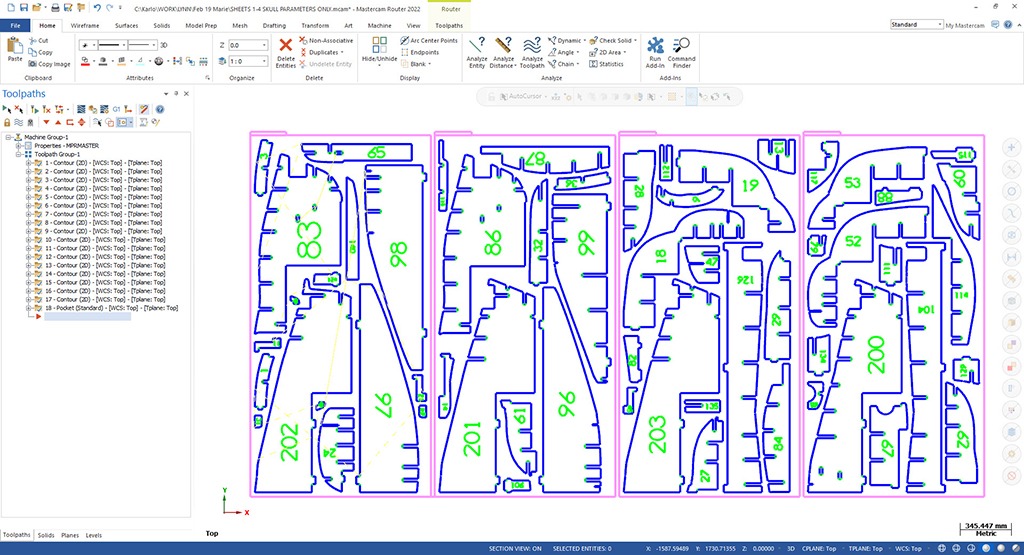

With Barbour’s permission, Jordan altered 1,000 slots manually, changing the clearance of each corner, without changing the outer profile of the car. The 277 part numbers were classified as geometric entities in the software and each one of them had to be changed to notes in order to nest properly. Mastercam’s Geometric Nesting feature under the Transform tab helped keep things uniform and organized.

Jordan learned to define the nesting sheet by setting the size of the sheet and plugging in how many were needed, select the appropriate chain which creates radiuses in each corner, and then grab the parts with toolpaths already programmed to set up the sheet. The nesting sheet looks similar to a puzzle, with the margins and parts spaced precisely to allow for lead in/lead out parameters. By saving each sheet to a Sheet Library, Jordan was able to cut the pieces uniformly so that they fit together precisely to build the car structure. The sheets were kept stable with the addition of tabs programmed at certain points along the base of the contour cut.

“A big part of the job involved setting the parameters and taking the chain from the last sheet and applying it to the next 20 or so parts in Mastercam,” said Jordan. “We didn’t change the outer profile of the car, we just changed how the mating parts meet.”

Jordan was able to print out each sheet depicting parts and part numbers for easy assembly. It took Jordan 40 hours to cut the buck. He delivered all 277 pieces and the nesting layouts he did in Mastercam to Barbour, who put the buck together like a big model car, in one day.

Customer Quote

“Mastercam is my whole business from start to finish. It speaks to the customer through visuals, it’s my design tool and the G-code for my machine. It’s also my quality control, enabling me to generate drawings for reference all along the way.”

– Marcel Jordan, Guelph, Ontario, Canada

Reseller Quote

“I didn’t know how I was going to organize all the parts. I was impressed with how organized and clean the job was, and how smooth everything went. That is what I learned through hours over the phone with Glen and technical support. In-House Solutions has their clients’ back. I couldn’t have done this car project without them.”

– Marcel Jordan, Guelph, Ontario, Canada