Lincoln Tech Makes the Grade with Intuitive CAM

The Indianapolis-based technical school relies on Mastercam’s ease of use and flexibility to train future programmers and machinists on a variety of CNC machines, improving its students’ odds of building successful careers in manufacturing.

Quick Facts:

Product Used: Educational Suite, Lathe, Mill, Multiaxis

Industry: Education

Project Details:

- The Challenge: Find an intuitive, easy-to-use CAM software that prepares technical school students for future employment and a range of industry demands.

- The Solution: Mastercam

- Benefits:

- Intuitive CAM software is streamlined and easy to use.

- CAM software is a gateway to understanding complex machines, including those with 5-axis or live tooling.

- Raster to Vector feature allows the user to pull an image into Mastercam and create geometry from it.

One institution benefitting from the U.S. technical-school enrollment upswing is the Lincoln College of Technology in Indianapolis, Indiana.

Students in Lincoln Tech’s CNC Machining and Manufacturing program gain career-building programming and machining skills and participate in enriching class projects. According to Michael Long, Lincoln Tech CNC instructor, a major part of this training hinges on the use of CAM software from Mastercam.

“Mastercam is an important part of our process,” said Long. “The software is our go-to for programming.”

The faculty at Lincoln Tech prepares students to meet the needs of future employers by teaching multiple machining methods. According to Long, each company wants something different, so the curriculum covers a range of industry demands. Some employers want more manual machining expertise while others need workers experienced in 3- to 5-axis machining.

“They want employees who can set up the machines, run parts, and do their jobs,” said Long. “Students are not coming here to land entry-level jobs and stop. Many want to take that next step to programming.”

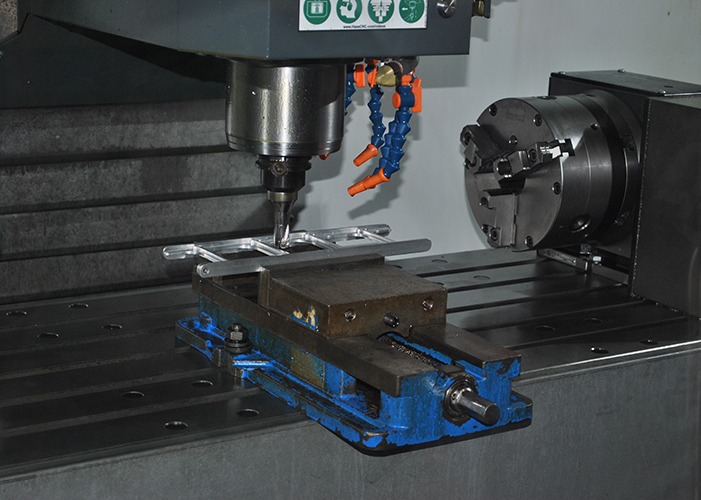

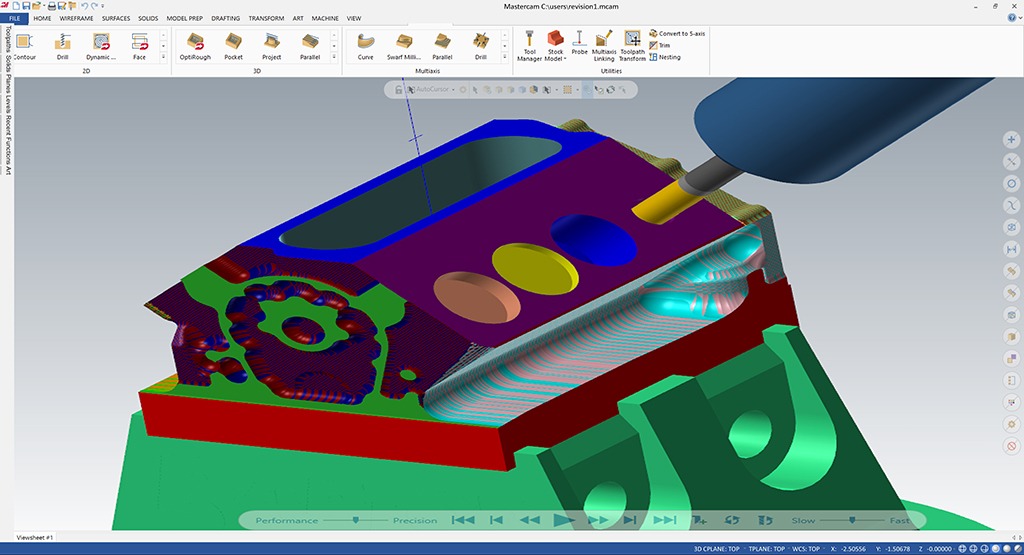

Mastercam is a gateway to understanding complex CNC machines, including those with 5-axis or live tooling. Many of the parts that Lincoln Tech students run are programmed in CAM software because there is simply not enough time to longhand everything.

“If you can program Mastercam, you can program just about any software out there,” said Long. “It is really streamlined and easy to use.”

Mastercam’s ease of use is a huge benefit for Lincoln students, especially when they work on special projects. A hand-cranked air compressor was one such project. The compressor is comprised of several parts, including a handle and feet, with tight tolerances on the internal components. In addition to ease of use, students benefit from the intuitive features of the CAM software.

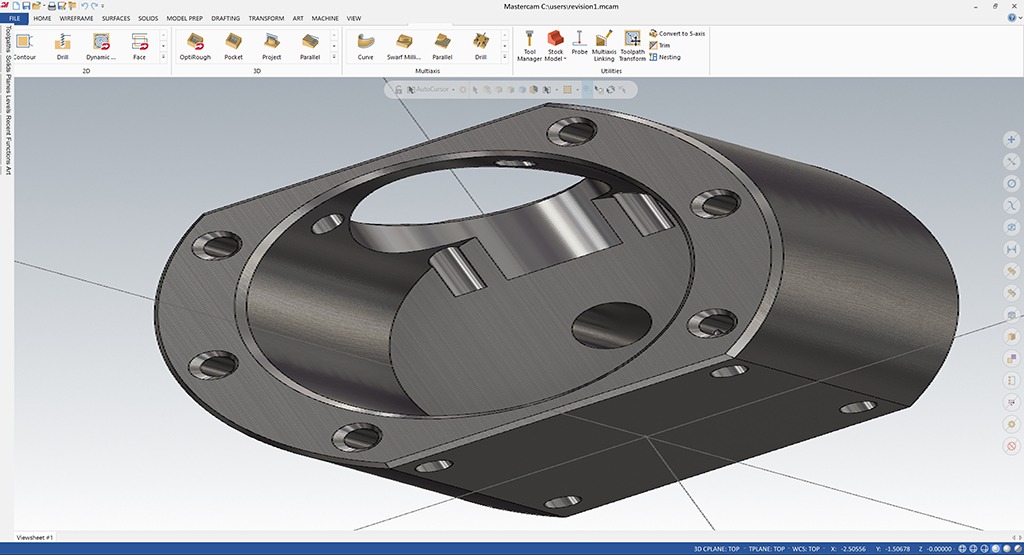

“One thing that stands out is plane control and creation,” said Long. “I like the way the Mastercam environment allows us to identify different planes to machine from to get that level of control.”

The curriculum for the CNC Machining and Manufacturing program includes ten courses including CNC Milling Set-up, Programming, and Operation; CNC Lathe Set-up, Programming, and Operation; Mastercam for the Mill; Modern Milling, Drilling, and Workholding; Mastercam for the Lathe; Advanced Multiaxis Machining; and Workplace Simulation and Job Readiness.

During the CNC Mill Set-up, Programming and Operation course, students learn to longhand program a mill, set it up, and run parts. Lincoln Tech instructors teach longhand programming, but most students will retain basic editing abilities. Similarly, in the CNC Lathe Set Up, Programming and Operation course, students longhand program a lathe, a task made easier thanks to canned cycles.

“One of the things I like about the CAM software is that you can actually output your turning codes in canned cycle format,” said Long. “You can program canned cycles within Mastercam. Being able to make those selections to put out a code that students can read through makes logical sense to them.”

Mastercam for the Mill covers program use and functions, drawing tools, and Dynamic Motion toolpaths. From optimized pocketing to highly specialized toolpaths, with Mastercam Mill, parts are produced faster and with greater accuracy, quality, and reliability.

Lincoln students appreciate the intuitive aspect of the CAM software and have a favorite feature: Raster to Vector. Located under the Wireframe tab, the feature allows the user to pull an image into Mastercam and create geometry from it. To better engage his students, Long uses the software features in creative ways throughout his courses. He challenged one group to cut metal parts and engrave their signatures on them.

Excited by the prospect of personalization, the students signed their names on pieces of paper, photographed the signatures, and pulled the images into Mastercam via Raster to Vector. The software then generated geometry from the images. Students programmed the machines and, within minutes, machined their signatures onto parts.

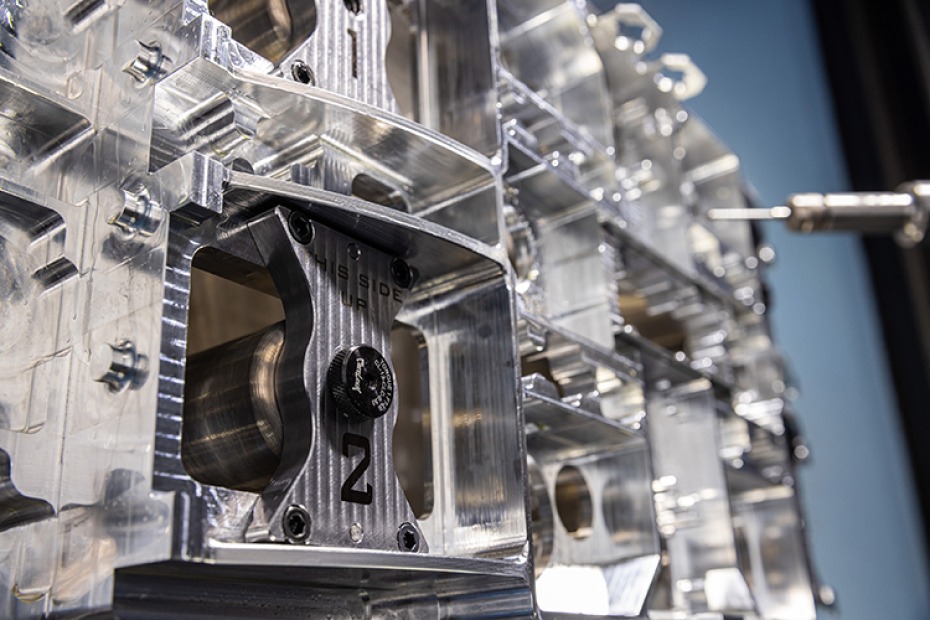

The Advanced Multiaxis Machining class begins with live tooling lathes and programming them in Mastercam. Students set up and run a few different parts before moving on to 4-axis programming and 5-axis programming and machining.

“For programming, we use Mastercam because trying to program 5-axis longhand—it’s not impossible, just foolish,” said Long. “Why would you longhand something like that when Mastercam exists?”

In Workplace Simulation, the final class of the ten-month program, students are assigned job roles and rotate those roles throughout the course, gaining exposure to a variety of job duties within a manufacturing environment. The hands-on approach to manufacturing training is paying off. Ninety percent of Lincoln Tech graduates were hired last year.

Customer Quote

“The software is our go-to for programming. I prefer the control it provides compared to what I’ve experienced from some other software packages.”

—Michael Long, CNC instructor, Lincoln College of Technology, Indianapolis, Indiana