When Local Industry Gets Involved

Most of the students graduating from the Machine Tooling Technics program at Chippewa Valley Technical College (CVTC) have earned a position or internship with one of the many manufacturing shops and plants in their surrounding Eau Claire, Wisconsin community. Their instructor, Dave Thompson, has provided his students with a curriculum and equipment suggested by their future employers to ensure that they have positions available to them in the surrounding industry.

QUICK FACTS

Product Used: Dynamic Motion, Mill, Lathe, Mastercam Educational Suite

Industry: Education

PROJECT DETAILS

- The Challenge: Bring software and hardware together in the classroom at a level that reflects the actual operations found in today’s industrial marketplace and encourages students to excel at the advanced pace required of automated manufacturing.

- The Solution: Mastercam, a CAD/CAM software keyed to modern CNC machine tools

- Benefits:

- Easy to teach and understand

- Stepped in skill advancement

- Accepted throughout industry

- Teacher assistance available as needed

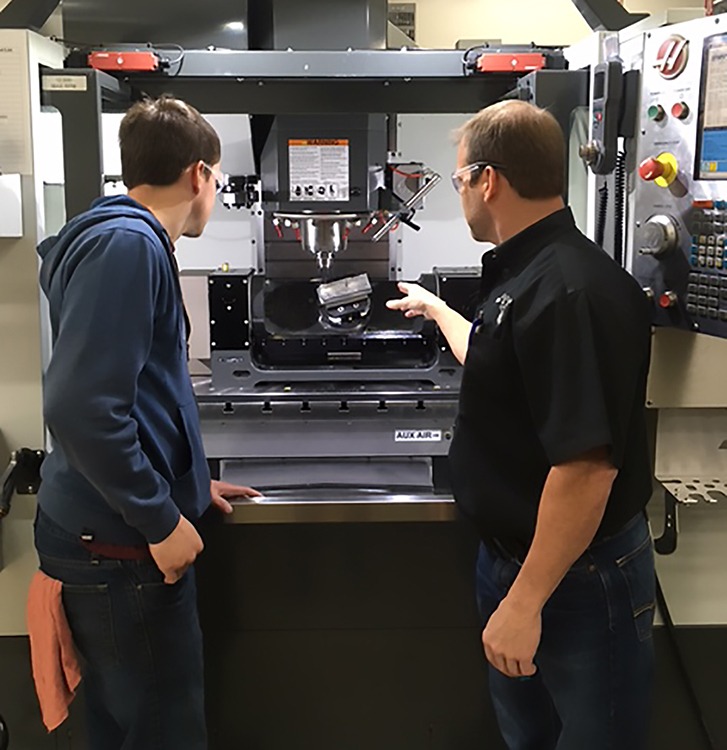

When you step into the shop area of CVTC’s Machine Tool Technics program, you will find no fewer than 13 Haas CNC turning centers, 6 of which have a Y-axis and live tooling, and 20 Haas CNC vertical mills, 4 of which are VM-2 models that can be fitted with Haas rotary-trunnion tables for 5-axis milling.

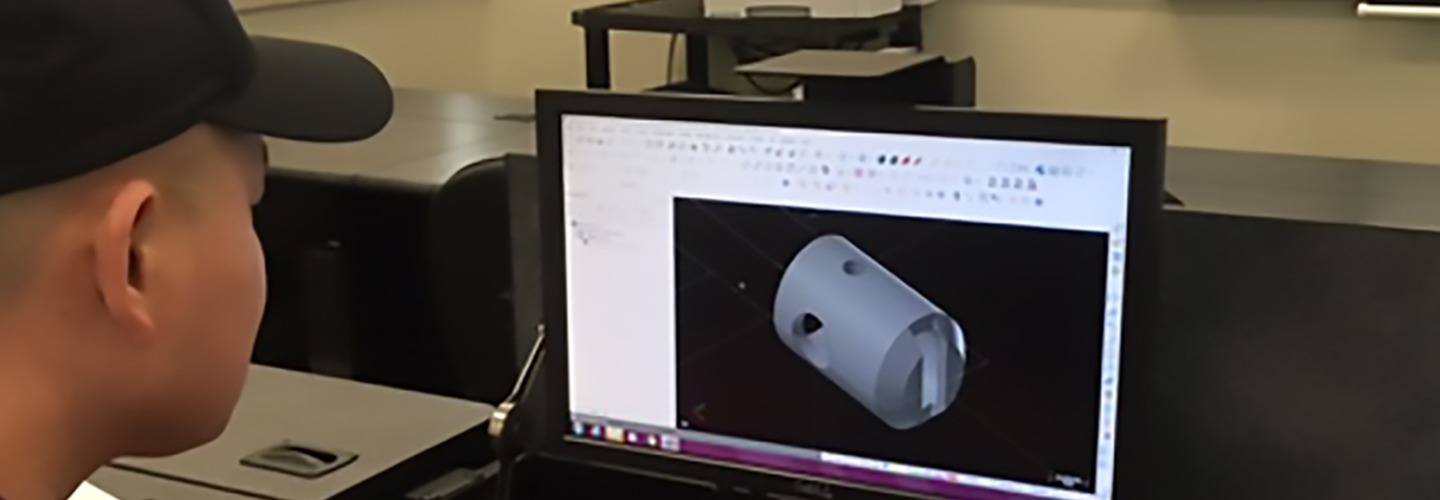

“We’re a Haas Tech Center,” says instructor Dave Thompson. “To keep pace with the advancements in automated manufacturing, we have Mastercam in our CAD/CAM (Computer-Aided Design/Computer-Aided Manufacturing) labs, so each student has his or her own station. We’re very grateful for the support both Haas and Mastercam have given us.

“The equipment, software, and even advancements in the program itself are due, in great part, to our local industry. We have an advisory committee comprised of shop owners and managers who tell us what our students will need to know to compete for jobs in the manufacturing community. They say that the features of the Haas machines will make them comfortable with what they’ll find in most plants, while Mastercam is programming software in place throughout Wisconsin’s industrial sector.”

After being exposed to an overview of manual machining in their first semester, learning the processes of milling, drilling, and turning, students are introduced to CAD/CAM. “One of our claims to fame is that we go really deep into understanding G- and M-codes in programming,” says Thompson. “When Mastercam gives them a code, they can read that code easily and understand what’s going on in the program. If there is ever an issue with their toolpath program, they may have to manually edit the program, adding or deleting certain information. Understanding the codes gives them confidence in achieving a good result.”

The next step in the course is to introduce 2D CAM with some drafting software. “Once they understand the drafting aspect,” shares Thompson, “they’ll learn how to program basic toolpaths for what they have drawn, primarily facing and contouring. Then, we’ll get into 3D CAM, learning about three-dimensional surfaces and importing their designs from SOLIDWORKS CAD programs. One of the projects they have to do at this stage is to design and build an injection mold body and cavity out of aluminum and then, using the shop’s molding machine, produce a plastic product. Our injection molding equipment is pretty basic, but it is very sufficient for our needs.”

At this point in the course, students will start getting into some of the machining processes, such as Mastercam’s Dynamic Motion technology, including Dynamic Milling and Turning. The technology lets the students experience fast cycle times when machining their projects while giving the college the benefits of extended life for their tooling with less wear on the mills and turning centers. The software generates toolpaths in a manner that is different from traditional CAM toolpath generation. [https://www.mastercam.com/dynamic/]

Mastercam takes into consideration not only the area from which metal is to be removed, but also the changing condition of the material throughout the various stages of machining. “This gives the students the advantage of faster machining times,” says Thompson, “with smooth, precise cutting operations that give their projects a professional look.”

The college’s relationship with the local industry extends well beyond having several individuals serving on the advisory committee. Because of the reputation gained through the thoroughness of the Machine Tooling Technics program, manufacturing companies in the region look to CVTC to fill an ever-growing need for qualified programmers and machine operators.

“Right now,” says Thompson, “there are seven jobs available for each graduate. We concentrate on both mold work and precision components because most of the industry in our region is comprised of mold builders and contract manufacturers. Our students are usually working in local companies by their second semester, with the companies accommodating each student with a work schedule that does not interfere with their college schedule. It is understood that the students will not be offered full-time employment, or receive advancements within the company until they complete our program. There are also several internship programs available at firms in the region for students in their fourth semester.”

Customer Quote

“Right now there are seven jobs available for each graduate. We concentrate on both mold work and precision components because most of the industry in our region is comprised of mold builders and contract manufacturers.”

—Dave Thompson, Instructor at Chippewa Valley Technical College, Eau Claire, Wisconsin