Calhoun Community College AMPs Up for Advanced Machining

Established over 70 years ago in North Alabama, Calhoun Community College serves more than 10,000 students from Decatur, Huntsville, and surrounding communities. The college offers 49 associate degree options, as well as 52 certificate programs, including the popular Machine Tool Technology program.

Quick Facts:

- Product Used: Mastercam Education Suite, Mastercam Multiaxis

- Industry: Education, Aerospace, Medical Device

Project Details:

- The Challenge: Preparing students for the 5-axis work commonly found in the aerospace and medical device manufacturing industries in and around Northern Alabama.

- The Solution: Mastercam Educational Suite, Mastercam Multiaxis

- Benefits:

- Mastercam’s Multiaxis toolpath capabilities to teach 5-axis machining

- Easy-to-use and learn

- The most widely used CAD/CAM software in the world

- Mastercam’s Multiaxis toolpath capabilities to teach 5-axis machining

- Easy-to-use and learn

- The most widely used CAD/CAM software in the world

“We have developed the Machine Tool Technology program to the point where there is typically more than one hundred students in the day and night programs working toward their associate degree and various certificates of proficiency. Of great importance to our Machine Tool Technology program is the efforts and collaboration of our advisory board which is made up of local manufacturing business leaders who share their expertise with us in the development of our curriculum, along the guidelines established by the National Institute of Metalworking Skills (NIMS®). The challenge has been the need to pace the curriculum toward a range of the students’ learning speeds,” said Tad Montgomery, Lead Instructor. This meant that there was no time to get into the more advanced aspects of CAD/CAM programming and CNC machining, such as 4- and 5-axis work.

“An early solution,” said Montgomery, “was to get involved with Project MFG™.” A collaboration of industry, academic, and defense partners in the U.S., Project MFG includes the Alabama Community College System, as well as such manufacturing industry leaders as machine tool builder Haas® and CNC Software, LLC., the developers of Mastercam CAD/CAM software. Calhoun Community College has 24 seats of Mastercam in their CAD/CAM lab and qualifies as a Haas Technical Education Center.

“We hand-picked several students from our Machine Tool Technology program to participate in the Project MFG Challenge Series of competitions,” said Montgomery, “and came in after hours to go beyond what we teach in our standard curriculum regarding multiaxis CAD/CAM and CNC machining operations. We did pretty well in the competitions, taking first- and second-place awards, and realized what we needed to teach to compete in the job market.”

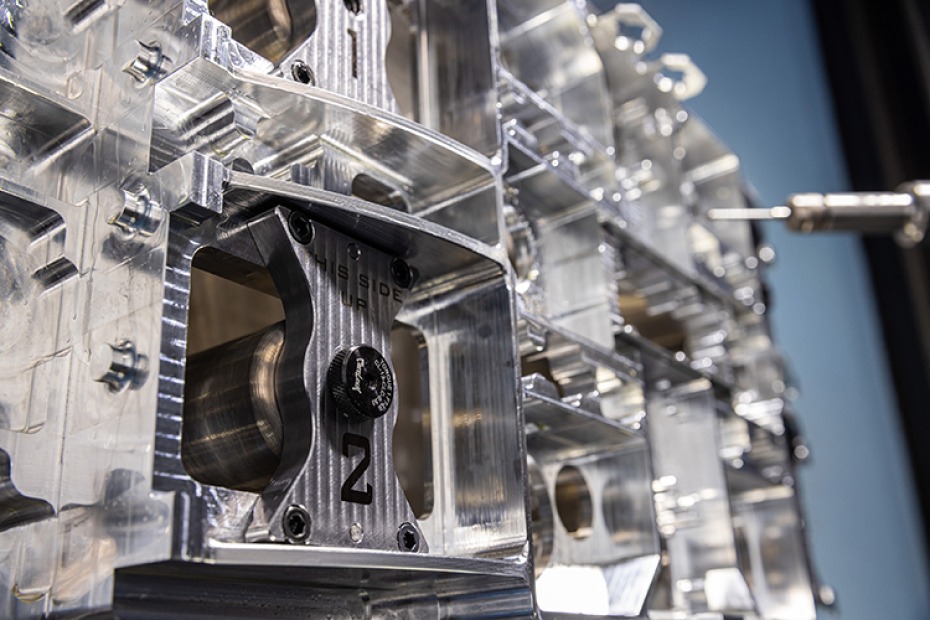

The Machine Tool Technology program provides students with a good diet of CAD/CAM and CNC machining to satisfy industry’s appetite for competent 3-axis skills. An increasingly pressing need, Montgomery realized, was for graduates who could handle the 5-axis work common to the aerospace and medical device manufacturers in North Alabama and surrounding areas.

The college’s solution was to form the Alliance for Machining Professionals (AMP), partnering with local companies such as Brown Precision, Inc., ATI, Dynetics Technical Solutions, In’Tech America, and M&J Precision Machining and Fabrication. Working closely with these partner/advisors, the instructors established a curriculum and co-op work program aimed at providing an opportunity for students to succeed at reaching a 5-axis level of proficiency.

“Because of the difficulty in understanding 5-axis programming and machining,” said Montgomery, “we established strict application requirements for students considering our AMP program. First, they must be at least 18 years old by June 1 of the application year. We look for candidates who have participated in STEM, Robotics Career Technical Coursework, or Project Lead the Way. We look at their ACT and other test scores, and they must be eligible to take Math 100 and English 101 at our college.”

Students must also sign a commitment that holds them to a high standard of attendance, proper attire, and professional behavior.

“We expect professional behavior from all our students,” said Montgomery, “but especially so from the students in the AMP program. They put in an eight-hour day here, twice a week, and spend three days a week at one of our partner manufacturers where they earn a salary. This makes our AMP program very attractive to serious students.”

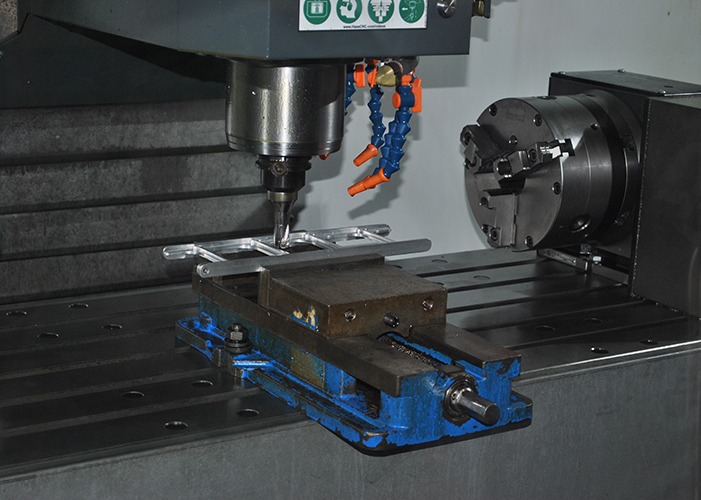

AMP students are indoctrinated into manual machining their first semester followed by CNC turning and CNC milling with SOLIDWORKS® and Mastercam in the second and third trimesters, respectively. During the fourth and fifth semesters, they use the Mastercam curriculum and materials for advanced CNC milling and turning. “Mastercam is extremely user friendly which is a real advantage, considering the complexity of multiaxis work. It’s also the industry standard, so it’s a benefit to teach the students the programming software they’ll probably be using in the work force,” said Montgomery. At the end of the fifth semester, students earn an Associate degree in Advanced Manufacturing with a major in Machine Tool Technology. During the sixth semester, AMP students are brought deeply into the world of Mastercam 5-axis programming and Haas 5-axis machining operations, earning a certificate proclaiming their skills in 5-axis Advanced Manufacturing.

For project work, students’ program and machine things they can take with them and use, such as parallels, 1-2-3 blocks, vice stops, screw jack sets, collets and speed wrenches, C-clamps, drill gauges, trailer balls, and machinist hammers with a storage compartment in the handle to accommodate a variety of tips.

“Although this is just our first year of AMP, our advisory board businesses have expressed pleasure at the results so far and look forward to having their workforces enriched by the quality of our graduates heading their way.”

Customer Quote

“Mastercam is extremely user friendly which is a real advantage, considering the complexity of multiaxis work. It’s also the industry standard, so it’s of benefit to teach the students the programming software they’ll probably be using in the work force.”

– Tad Montgomery, Lead Instructor, Machine Tool Technology Program, Calhoun Community College