CAD/CAM at Bloomsburg Helps Build Better Bots

Instructor Kirk Marshal’s Technology Education class at Bloomsburg Area High School in Bloomsburg, Pennsylvania, has been entering their battling robots at national BattleBots® IQ and National Robotics League events for many years. These survival-of-the-fittest contests are held at various venues around the country. Not only have they been competing, they have been winning. Mr. Marshall attributes much of their success to his students’ CAD/CAM skills.

Quick Facts

- Product Used: Mill, Educational Suite

- Industry: Consumer Goods, Education, Robotics

Project Details

- The Challenge: Encourage students to learn the school’s CAD/CAM curriculum as it advances in functions and complexity.

- The Solution: Educational Suite, Art

- Benefits:

- Mastercam is easy to teach and easy to learn

- Dynamic Milling toolpaths provide faster, precision operation

- CAM curriculum that dovetails with those at many colleges

- Students learn skills needed at today’s manufacturing companies

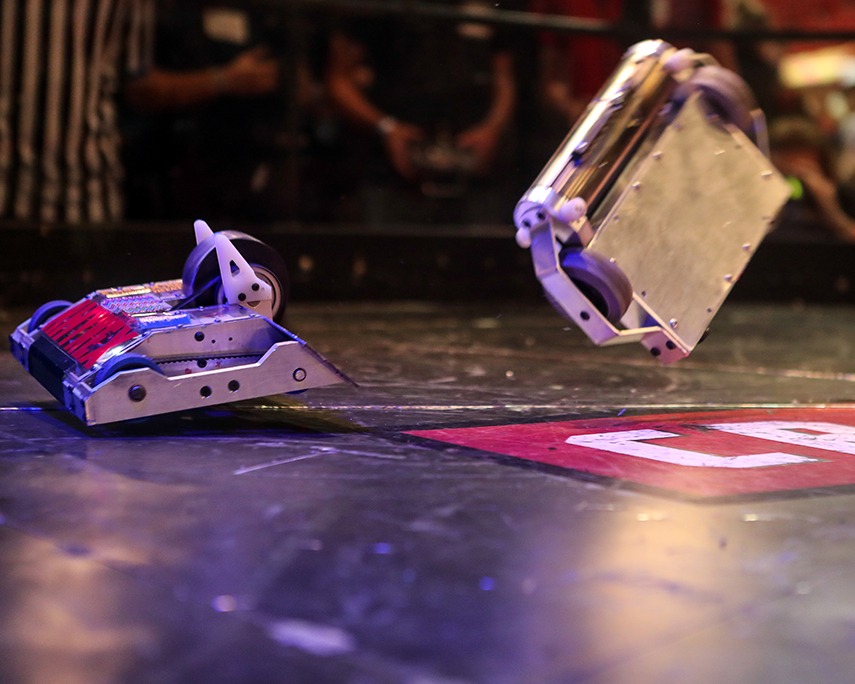

The robotics program at Bloomsburg High has grown during the past twenty years from a desire on the part of Marshall to take his Technology Education students beyond the less challenging projects such as cutting boards, book racks, and coasters and into the more complex Computer Aided Design and Computer Aided Manufacturing environments found in the world of BattleBots. He has always let them pick items that are of interest to them that can be designed and created using a number of different platforms in plastics, glass, wood, and metals. He wants them to see how items familiar to them are produced in today’s modern businesses using automated manufacturing processes. “Designing and building BattleBots seemed to offer a lot of CAD/CAM possibilities,” said Marshall. “Besides, I watched some battles on a TV show and it looked like a lot of fun. When you combine fun, with what I wanted to teach them in advanced CAD/CAM curricula, that’s a win-win for all of us.”

A BattleBot begins with a lot of design work. “What do we want it to look like, what weapon do we want it to deploy, and what about defensive capabilities, are just some of the questions kicked around in the design stages,” said Marshall. “The students do a lot of the designing in SOLIDWORKS. Once a design is agreed on, all of its components from framework to weapon to outside armor are downloaded to Mastercam to create the toolpaths for our CNC mill.” Students machine each piece out of wood first, using Mastercam to proof the CAM program. Wood is forgiving and will not result in broken tools if a wrong feed, speed, or dimension has been entered. There are fifteen Mastercam workstations set up in the classroom, enough for all participants.

Once the program has been proven, the actual components for the battling robot are machined out of aluminum and steel. For each piece, a computer file record is maintained. “Mastercam lets us program part tolerances that often need to approach a thousandth of an inch,” said Marshall. “We have a new CNC mill that lets us take advantage of Mastercam’s Dynamic Milling feature. The tool flies around the part so fast, it’s amazing. We actually cut a weapon blade for our latest battling robot out of inch-and-a-half thick S7 tool steel, in a single pass. All I could think was, ‘this is awesome.’ This weapon blade is six inches in diameter and spins at 12,000 rpm. Whatever competing BattleBot it hits, it destroys. Mastercam has given us the ability to field competitive BattleBots year after year. I introduced Mastercam into my curriculum back in the 1990s and have updated and used it consistently with my students in a wide range of CAD/CAM projects. I find it important to get them familiar with the software they will most likely find in the manufacturing companies where they’ll seek employment.”

Many of the area’s manufacturing companies are also sponsors of the school’s battling robot team. In return for a fee, they get their names and logos on signs and banners in the arena areas, on programs, T-shirts, and other team paraphernalia, just like NASCAR. “I send out brochures detailing our battling robots program and what we hope to achieve. Because the manufacturers have come to realize the skills our students have upon graduation, those students not going on to Penn College or other technical schools are warmly received into the local and regional workforce.”

Through an arrangement set up between the schools, students that complete Kirk Marshall’s CAD/CAM courses and pass a final exam offered by the Penn College NOW program, earn college credit. In the past two years, 16 students have passed the exam to receive 7 college credits. “Penn College has a great automated manufacturing program,” he said. “Not only are they Mastercam users but they are a machining technology center with both 2- and 4-year degree programs. My courses dovetail with those at Penn and other colleges, providing many opportunities for our students to advance their education while still in high school.”

“Mastercam has given us the ability to field competitive BattleBots year after year. I introduced Mastercam into my curriculum back in the 1990s and have updated and used it consistently with my students in a wide range of CAD/CAM projects. I find it important to get them familiar with the software they will most likely find in the manufacturing companies where they’ll seek employment.”

Kirk Marshall, Technology Education Class Instructor, Bloomsburg Area High School