CNC Post Processor

Power your CNC machines with advanced post processors, built for accurate output and maximum efficiency.

Optimize your workflows with advanced CNC post processors

Unlock the full potential of your CNC machines with our advanced post processors. These essential tools translate toolpath data from your CAD/CAM software into precise NC code tailored to your machine’s configuration.

Our post processors ensure accurate and efficient machine code by considering your machine’s kinematic setup, control syntax, and advanced control options.

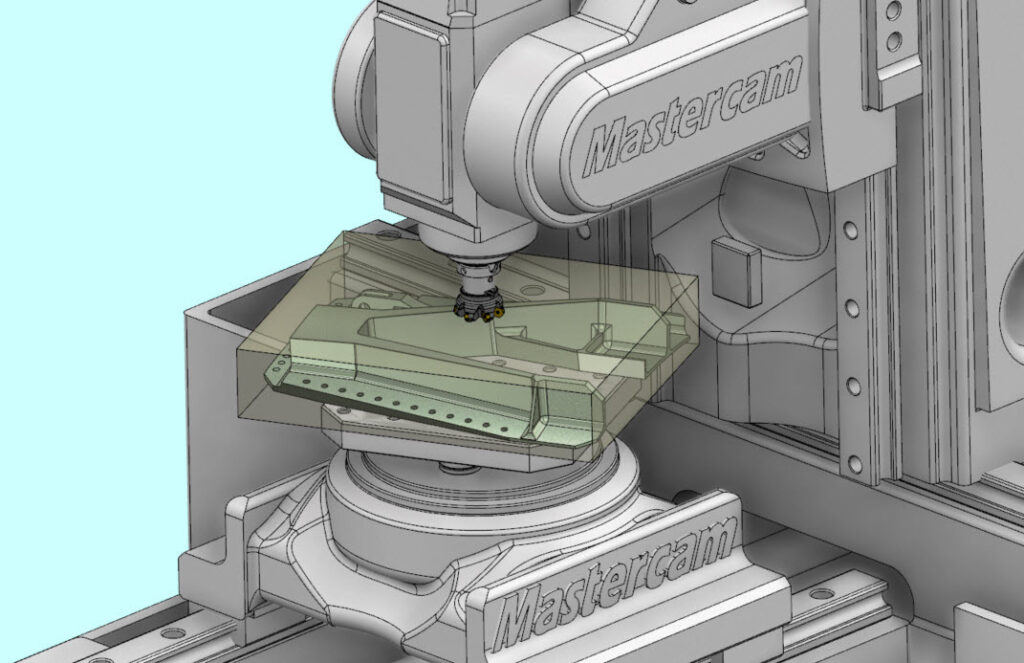

Visualize and optimize with machine simulation

Experience seamless integration with our machine simulation environments, allowing you to visualize operations as they would run on your machine without leaving the Mastercam software. Identify machine travel limitations, potential collisions, and visualize part finishes virtually, saving valuable machine time and material. Our post-driven simulation accurately mirrors the motion defined by the output NC code, ensuring that any changes made to your post processor are reflected in the simulation.

Explore powerful CNC post processors

Talk with us about CNC post processors that optimize your machines and boost productivity

Custom post processor development and expert consultation

Need something more specific? Our team of engineers is available for custom development to tailor your post-processor output to meet your unique machine and process requirements. If you have questions, our experts are ready to provide consultation and support for your specific application challenges.

Looking for something else?

Our CAD/CAM software products take parts from design through to the production line. Program your manufactured parts with leading-edge features for precision and efficiency. Creating code to drive your CNC equipment is what Mastercam does best.

Build your comprehensive CAD/CAM solution with Mastercam. Enhance your productivity with a variety of specialized Add-Ons for your specific machining needs.

Mastercam partners with top CAD/CAM software integration experts in the manufacturing industry, so you can choose from complementary software tools, hardware, and more to boost your bottom line with a complete manufacturing solution.

Mastercam offers several plug-in post processor solutions for converting generic CAM system output to Mastercam-specific NC code.

CP6 post processor application

Download the latest version of the CP6 post processor application for use with Mastercam X9-2025. Note, this product requires a purchased license of CP6.

Access Custom Post Processor Solutions

Partner with us to create solutions that match your machines, controls, and production goals.

CAD/CAM Post Processor FAQs

Post processing software takes the toolpaths created in a CAD/CAM program and translates them into machine-specific instructions. These instructions include the control syntax, motion limits, axis configurations, and advanced options your CNC equipment requires. Without this step, the generic toolpath data would not match the way each machine actually operates.

The post processor ensures that the code sent to the controller accounts for kinematics, tool changes, spindle speeds, and safety moves. By tailoring the output to the machine, it reduces errors, improves efficiency, and produces reliable results.

CloseThe best CNC software depends on your shop’s goals, the machines you run, and the complexity of your parts. Some shops need simple 2D programming tools for routing or drilling, while others require advanced multiaxis strategies, simulation, and automation to handle complex jobs at scale. The right software should balance ease of use with flexibility, giving you accurate toolpaths and reliable output while also adapting as your production grows.

Key factors to consider include compatibility with your equipment, support for different machining processes, verification features to catch errors before they reach the machine, and access to training or a strong user community. Mastercam offers these capabilities along with a trial Mastercam Learning Edition that lets you practice programming, explore toolpaths, and gain confidence before running parts on the shop floor. Combined with extensive training resources and global support, it helps manufacturers improve productivity while keeping operations consistent and reliable.

CloseMost CAD/CAM providers let you download post processors from their websites, customer portals, or authorized resellers. You start by identifying the exact machine and control you want to support, since each post processor matches a specific setup. After confirming compatibility, you download the package and install it directly into your CAD/CAM environment.

Some posts come free and ready to run, while others require a license or additional customization before they work with your equipment. Providers often supply documentation or setup guides to walk you through installation. If your machine needs advanced functions, you can request a tailored post from a reseller or engineering team to align the output with your production requirements.

CloseYes, a custom post processor can be built to match the exact requirements of your CNC machine and workflow. While standard posts handle most operations, many shops need specialized code for unique kinematics, multi-axis motion, probing cycles, or advanced control features. A custom post ensures the output matches your equipment without workarounds or manual edits.

Building one usually involves collaboration between programmers and application engineers. They analyze your machine’s setup, control syntax, and safety needs, then adapt or develop a post to fit. The result is code that runs reliably, protects your equipment, and supports your production goals. Custom posts are especially valuable when you run high-complexity parts or use advanced machines that off-the-shelf posts cannot fully support.

CloseA post generator is a tool that creates or customizes post processors for CNC machines. Instead of starting from scratch, it provides a framework that developers or application engineers use to define machine-specific details such as axis configurations, control codes, and safety routines.

By using a post generator, you can adapt generic CAM output to match the exact requirements of a machine’s controller. This ensures the G-code or machine instructions follow the right syntax, account for kinematics, and run reliably on the shop floor. Post generators enable fine-tuning output for complex machines, adding advanced functions, and reducing the need for manual code edits.

Close