Mill-Turn

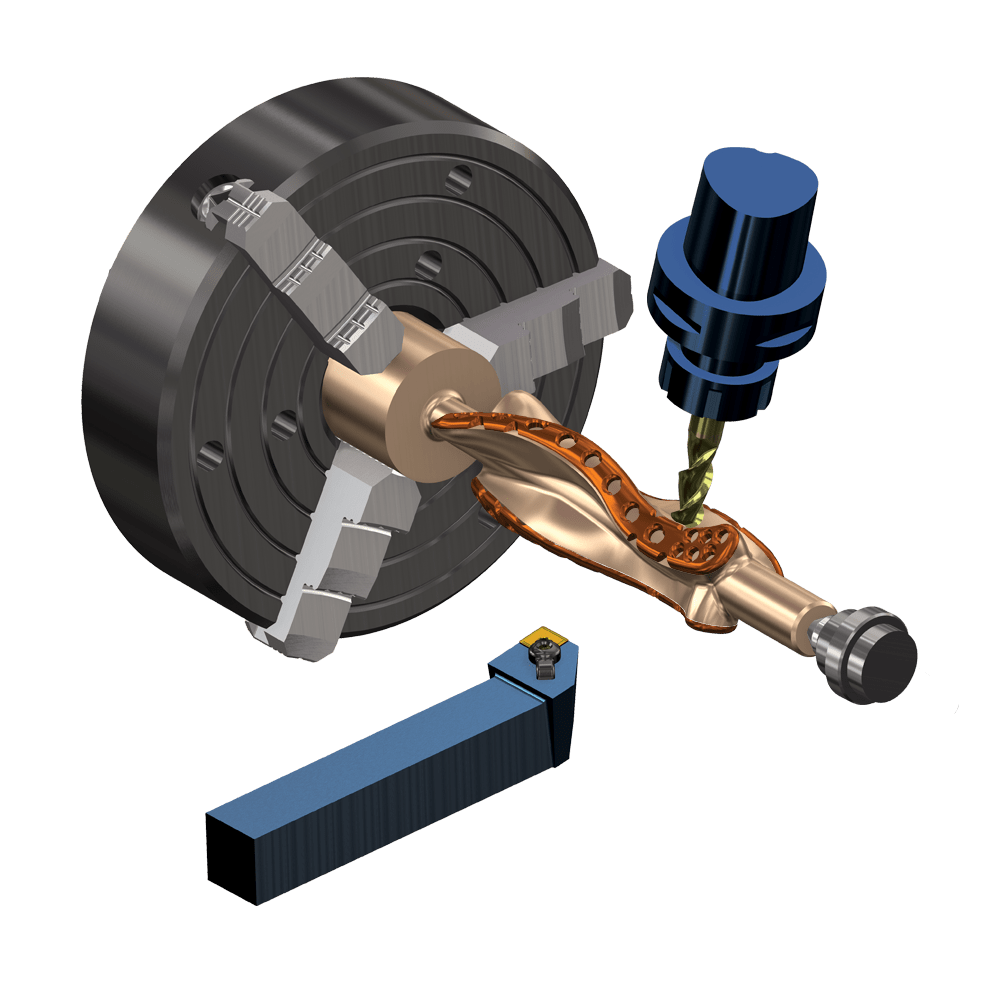

Mastercam Mill-Turn programming streamlines high-power multistream machine centers for increased performance and safety. These multitasking CNC machines reduce multiple setups, manual part handling, redundant fixturing, and idle time for improved productivity in manufacturing.

Using Mastercam’s proven milling and lathe toolpaths, this software simplifies the programming process for mill-turn machines with job setups keyed to the exact machine in your shop.

- Optimization, synchronization, and visualization in a single platform.

- Automation to easily manage complex operations between multiple machine data streams.

- Efficient milling, turning, and drilling operations with fewer setups at high speed.

- Program simple lathes in addition to complex machines.

This lathe mill combination programming software provides a set of routines to program complex parts and test your cutting strategies in a single environment—before your stock is on your multitasking machine. You can use Mill-Turn to machine parts without fear of costly collisions or machine damage.

- Automated job setup

- Intelligent, stock-aware toolpaths

- Powerful Gantt- or Tree-style synchronization

- Intuitive part handling tools specific to your machine

- Full machine simulation with accurate visual feedback

- Powerful multiaxis cutting

Mastercam Mill-Turn provides a custom machining environment in which the machine configuration and limits are captured and displayed graphically to ensure safety and quality.

Find a Reseller

If you are looking to find your Reseller, click on the link below.

Features

CAD for CAM

A full design package based on a machinist’s needs, including wireframe, surfaces, and solids design; open most CAD files in Mastercam to access modeling and prep tools for CAM programmers to get parts on and off machines quickly.

Advanced Technology

Mastercam’s proven toolpaths, intuitive part handling, automated job setup, 3D tooling support, customized milling tools optimized for mill-turn machining, deburring, support for 2- through 5-axis toolpaths, multiturret, multispindle, and more—all managed in a single machine environment.

Advanced Toolpaths

Detect collisions between your stock, tool, and machine components before sending code to your machine tool. Machine Simulation is a safe way to prove out 3-axis, 4-axis, or 5-axis toolpaths to make clean, efficient, and accurate programs.

Mastercam Code Expert

Optimize machine movement and synchronization between turretsand spindles with this state-of-the art interface to generate accurate and efficient code.

Dynamic Motion™

Extend tool life with proprietary toolpath strategies that maximize material removal rate and reduce cycle times.

Flexibility

Mastercam Mill-Turn allows you to have a complete post, additional tools made for those machines like pinch and balanced turning, and ease of use for twin spindle, twin turret, and B-axis head machines.

Benefits

As a result of being part of the Sandvik network, Mastercam Mill-Turn users get the benefits of industry-leading technology like PrimeTurning™ automated toolpath strategies and CoroTurn® tools.

System Requirements

See the table below for minimum and recommended system configurations for Mastercam. These recommendations are based on systems we have in use at CNC Software for testing and evaluation purposes. Our recommendation is to get as much power (processor, video card, and memory) for your systems as you can afford.

| Minimum | Recommended | |

|---|---|---|

| OS | Windows 10 or Windows 11 64-bit Professional | Windows 10 (version 20H2 or later) 64-bit Professional |

| Processor | Intel® or AMD 64-bit processor, 2.4 GHz or faster | Intel i7 or Xeon® E3, Kaby Lake or later, 3.2GHz or faster |

| Memory | 8- 12 GB | 32- 64 GB |

| Video | OpenGL 3.2 and OpenCL 1.2 support with 1 GB memory. No onboard graphics. | NVIDIA RTX or AMD FirePro™ / Radeon Pro card with 4 GB (or higher) dedicated memory. |

| Monitor | 1920 * 1080 resolution | 1920 * 1080 resolution, dual monitors |

| Storage | Hard drive with at least 20 GB free USB and/or DVD drive (depending on installation media and licensing method) | Solid State Drive (SSD) with at least 20 GB free |

| 3D Mouse | 3Dconnexion 3D mouse |

Operating Systems

Mastercam continues to review the operating system (OS) requirements to provide the best possible user experience for our customers.

We recommend Windows Professional editions with all latest updates installed. While Mastercam may run on other Windows editions (such as Home Edition) or virtual environments (such as Parallels for Mac), it has not been tested on these configurations and is therefore not supported.

For Windows 10, we recommend version 22H2 64-bit Professional editions.

Mastercam 2022 was the last release available for Windows 7 and 8.1.

Mastercam 2023 and later fully support Windows 11.

Processor

The processor speed will impact how fast the software will calculate and complete tasks. With each release, more and more aspects of Mastercam are becoming multi-core processor aware. Toolpath calculation and Simulation will generally run faster with a multi-core processor. We typically see a 50% reduction in toolpath calculation time with the latest Intel processors.

Memory

When Mastercam uses all available RAM, it switches to using virtual memory space, which is stored on the hard drive and will dramatically slow the system down. We recommend a minimum of 8 GB of memory. For large toolpath generation and simulation, we recommend 32GB of RAM.

Video

When purchasing a new computer for Mastercam, one of the most important components is the video card.

We recommend an NVIDIA RTX or AMD FirePro™ / Radeon Pro card with 4 GB or more of memory. Other graphics cards can be used, but they must offer full OpenGL 3.2 and OpenCL 1.2 support. OpenCL is required for Mastercam to be able to redirect certain computation tasks to the graphics card to increase system performance.

We do not recommend or support the use of onboard graphics found with some PC configurations. These do not generally have the capability to drive graphics intensive applications such as Mastercam.

Make sure you are using up-to-date drivers from your card manufacturer. We often see issues that are resolved with updated video drivers. The driver version can have a great impact on how the card performs.

The latest drivers for NVIDIA and AMD can be found on their websites. We recommend using the automatic detect feature to detect which video card is installed. More information on configuring the graphics card can be found at this Mastercam knowledge base article.

Monitor

Most of our internal systems utilize dual monitors and we find this to be a more productive setup. Mastercam displays on the primary monitor while applications such as Mastercam Simulator, Code Expert, or Tool Manager display on the secondary monitor.

The minimum recommended resolution for the primary display is 1920 * 1080 resolution typical of widescreen monitors available today. Mastercam will run on lower resolution screens but beware of potential sizing issues with larger dialog boxes and panels which may be awkward to work with. Lower resolution monitors may work fine as a second monitor in a dual screen setup.

Mastercam will run on large format displays, including 4K monitors and high-DPI devices however, we do experience some display issues with these configurations.

Storage

We have found that one of the best computer upgrades is to invest in a Solid-State Drive (SSD). These drives are now priced at a point which makes them a good investment. Many of our test systems employ a smaller primary SSD for the OS and installed applications, with a second large capacity conventional drive for data.

3D Mouse

A 3D mouse improves the way you interact with your 3D application. It is designed to be used by your non-dominant hand in tandem with a standard mouse for a balanced and cooperative work style. You gently manipulate the 3D mouse’s controller cap to simultaneously pan, zoom and rotate 3D content while your standard mouse is free to select menu items or parts of the model. Additional technical and purchase information can be found on the 3Dconnexion website.

Anti-Virus Software

Most computers today have some kind of anti-virus software to protect from unwanted malware. In some cases, these have been found to interfere with applications such as Mastercam which are running on the computer. CNC Software does not recommend specific anti-virus products, but if you see unexpected issues, it may be a conflict with anti-virus software. Try temporarily disabling the anti-virus software or setting an exception for Mastercam.

Close

Case Studies

Mill

Mill

3D-Machine, Inc.

Before using Mastercam Lathe Custom Thread toolpath, producing a hoist drum—including machine set up, tooling, and machining—took at least 40 hours. With the CAM toolpath, 3D-Machine, Inc. produced the part in just seven hours. Mill

Mill

Achates Power

Achates Power in San Diego, California, uses Mastercam to create prototype parts for an eco-friendly, gasoline compression ignition, opposed-piston engine. The collaborative research was the work of Achates, Argonne National Laboratory, and Delphi Technologies. It was produced using funding from the U.S. Department of Energy’s ARPA-E program.Mastercam Community

When you choose the world’s most widely used CAM, you gain benefits beyond the technology driving our software. Our global community of Mastercam users, experts, educators, and enthusiasts helps you get the most from your investment.

FAQs

A mill-turning machine performs subtractive manufacturing, where material is removed through strategic cutting techniques. On a mill-turning machine you have the capabilities of a mill, where the tools move around a piece of stationary stock material, combined with the capabilities of a lathe, where the tools move on a spinning piece of stock. A CNC mill-turning machine is capable of cutting parts as programmed by a CAM software like Mastercam.

CloseA CNC mill-turn machine is programmed like all computer numerical control machines, with a CAM software. Software such as Mastercam is used to create efficient machine motion using G-code to program the CNC mill-turning machine and automate the manufacturing process.

CloseCNC milling is a subtractive manufacturing process where the tools move around a stationary piece of stock material that is held in place with a variety of fixturing options. In CNC turning, material is similarly removed from a piece of stock material, but instead of being stationary, it is spinning in a lathe assembly.

CloseMill-turning machines introduce complexity not seen in many other milling machines or lathes. Mill-turning machines often include multiple turrets with different tools, some of which can engage the part at the same time. For this reason, the most important aspects of safe and efficient mill-turn programming are 1) robust mill and lathe programming techniques, and 2) the ability to properly synchronize tool motion from multiple locations.

CloseCNC mill-turning software eliminates errors that can occur when manually programming a CNC mill-turning machine. It also allows adaptability and offers methods of precision machining that are impossible through manual programming.

Close