Energy

Mastercam Software for Energy Manufacturing Solutions

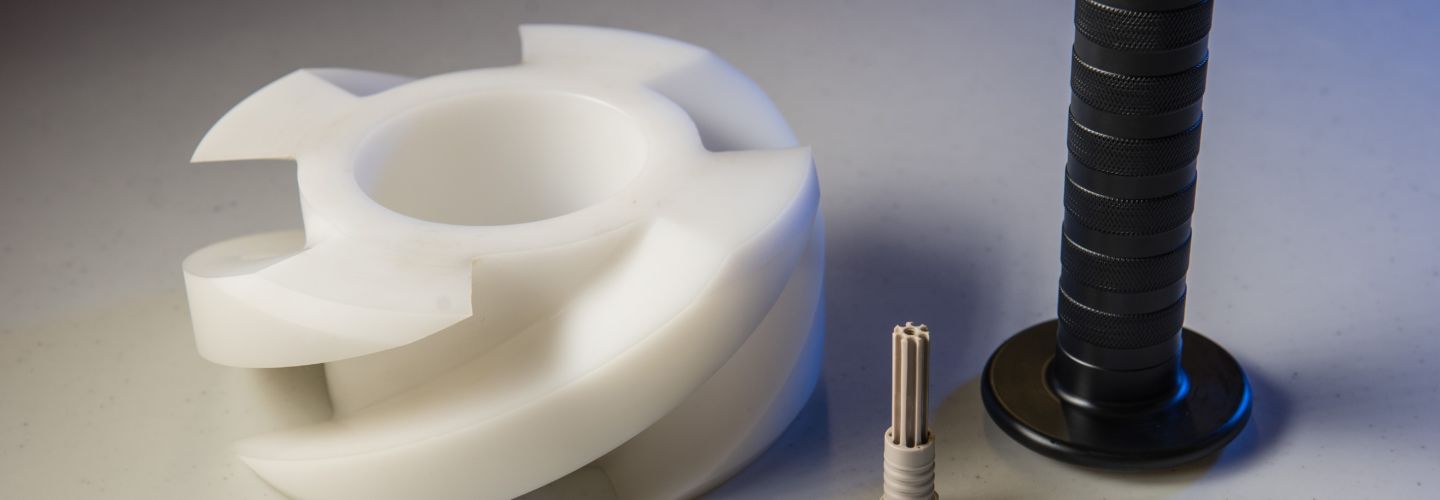

Manufacturers in the Energy industry require precision, flexibility, and fresh innovation. What better way to achieve this than with the latest energy industry CNC software from the world’s number one CAM system? From Fortune 500 energy corporations to start-up companies in renewable energy and suppliers to windmill and oil drill bit producers, manufacturers trust Mastercam to meet productivity and precision requirements across all sectors of the energy industry.

In the Energy manufacturing industry, success depends on speed and quality in the production of parts and components. Mastercam provides CAD/CAM software to meet the rigorous demands of energy production and power generation, including:

- The latest CAM tools for solving complex machining issues.

- Efficient toolpaths that conform to forgings and castings.

- Streamlined 5-axis cutting, trimming, and drilling.

- Dynamic Motion™ boosts tool life and decreases cutting time.

- Intelligent toolpaths that efficiently target uncut areas.

Mastercam Software for Energy Manufacturing Solutions

We have developed the largest global network of CAM partners to give our users in Energy sectors the tools they need to make their production challenges disappear. Our solutions take advantage of the latest technologies developed by tooling, software, and machine tool manufacturers worldwide.

Mastercam sets the standard for CNC programming with flexible options for Energy manufacturing. You will find a variety of comprehensive CAD/CAM solutions to import, design, and program parts on a range of machines to rigorous specifications and demanding production schedules.

In the Energy industry, manufacturers have diverse machining requirements, and we offer the software tools to complement the precision needs of your shop, from design to turning to multitasking, wire EDM, and more. Check out the full array of Mastercam products to find the right solutions for your manufacturing challenges. If your shop does it, we can support it.

Find a Reseller

Contact us to explore CAD/CAM software for improved Energy Manufacturing solutions

Case Studies

Mill

Mill

3D-Machine, Inc.

Before using Mastercam Lathe Custom Thread toolpath, producing a hoist drum—including machine set up, tooling, and machining—took at least 40 hours. With the CAM toolpath, 3D-Machine, Inc. produced the part in just seven hours. Lathe

Lathe