Consumer Goods

Mastercam Software for Consumer Goods Manufacturing

Consumer Goods manufacturers seek greater product design and manufacturing productivity while cutting costs and maintaining quality.

Designing consumer packaged goods cross the widest range of machining applications. That is why so many Consumer Goods manufacturers turn to Mastercam’s manufacturing software. From our complete line of design-for-manufacturing tools, to applications covering 2D through multiaxis machining, turning, mill-turn, and wire EDM, there’s virtually nothing that Mastercam cannot automate.Manufacturers in Aerospace and Defense seek manufacturing technology for quality and precision at an exceptionally high level. What better way to achieve this than with the latest defense and aerospace manufacturing software from the world’s number one CAM system? Trust Mastercam to bring precision and efficiency to your finished parts, with unrivaled metal removal processes for even the toughest aerospace and defense grade materials.

In Consumer Goods manufacturing, success depends on precision, reliability, and speed. Mastercam provides CAD/CAM software solutions to meet the rigorous demands of industry in this field, including:

- Ability to import, create, or cut virtually any CAD model.

- Wide range of CAM tools for solving complex machining issues.

- Dynamic Motion™ boosts tool life and decreases cutting time.

- Intelligent toolpaths that efficiently target uncut areas.

- Streamlined interface and easy upgrade path.

- Ability to machine in hardened tool steels to exact specifications.

- High production turning of component parts.

- Creation of complex die/molds used in manufacture of consumer products.

Mastercam Software for Consumer Goods Manufacturing

Consumers expect the best, and Consumer Goods manufacturers are looking for affordable ways to maximize productivity and meet that expectation. Manufacturing Consumer Goods depends on reliable precision, flexibility, and delivering just the right finish. From small shops producing specialized pieces to large companies mass producing popular items, everyone involved requires CAD/CAM software that can live up to the increasing demands of the industry.

Software that is ideal for Consumer Goods is only one ingredient for success. Collectively, our global community of Mastercam users, experts, educators and enthusiasts form a valuable resource of knowledge and innovation. And our Mastercam Representatives bring years of practical experience in various industries and local markets, helping to ensure that you always have the support you need to get the most out of your CAD/CAM investment.

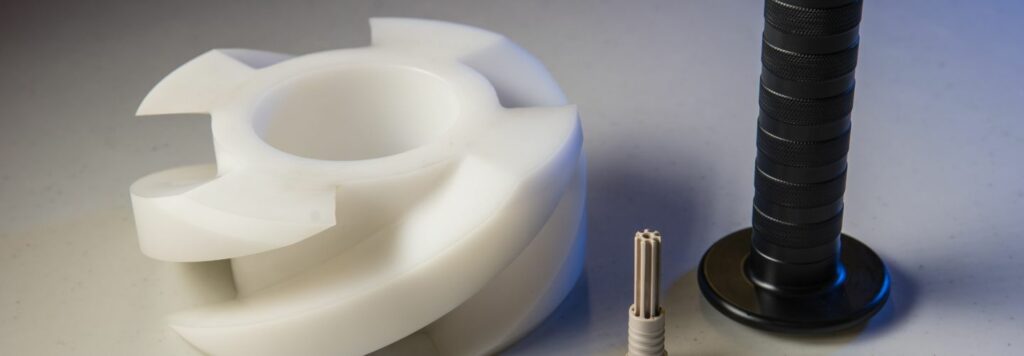

Our array of machining solutions and proprietary toolpaths is the industry standard in Consumer Goods. Attention to detail, along with superior, high-quality surface finish makes Mastercam the definitive tool for the production of parts and molds.

In Consumer Goods, speed and reliability are paramount, and we offer the tools to support the precision needs of your shop, from design to turning to multitasking, wire EDM, and more. Check out the full array of Mastercam products to find the right solutions for your manufacturing challenges. If your shop does it, we can support it.

Add-Ons

Contact Mastercam

Success Stories

3D-Machine, Inc.

Before using Mastercam Lathe Custom Thread toolpath, producing a hoist drum—including machine set up, tooling, and machining—took at least 40 hours. With the CAM toolpath, 3D-Machine, Inc. produced the part in just seven hours.

APS Plastics Success Story

APS Plastics & Manufacturing (Tomball, TX) has been machining custom composite components since 2006. In 2016, the company was acquired by Framework Capital Partners, an investment firm committed to optimizing manufacturing practices. Led by CEO Mushahid (Mush) Khan, APS specializes in small high-precision components made of thermoset plastic composites, glass films, and other plastics measuring from 0.030” to 25” in diameter for inclusion inside valves, high-end electrical connectors, and insulators for the energy, medical device, and electronic device industries. The non-corrosive composites are suitable for harsh, corrosive environments.