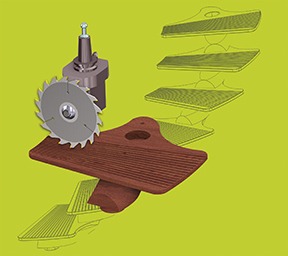

Mastercam 2020 Router Showcased at AWFS

The Association of Woodworking & Furnishing Suppliers Fair will be held July 17-20 in Las Vegas, Nevada. Attendees at the 2019 AWFS Fair will have access to the latest in the line of powerful Mastercam machining software. Stop by booth # 7844 at the Las Vegas Convention Center for a look at Mastercam 2020 Router, with features and enhancements that streamline your entire process, from job setup to job completion.

Mastercam provides leading CAD/CAM solutions for woodworking applications. Mastercam 2020 Router helps increases machining productivity and reduces overall production costs with new 2D through multiaxis routing automation features, CAD and model preparation improvements, and more.

CNC Programming

Mastercam 2020 continues to increase productivity and programming efficiency, while reducing overall production costs, with a series of automated 2D through 5-axis toolpath improvements. The new 3D Blend toolpath is based on the Surface Finish Blend toolpath, but is faster with a superior quality, and provides stock and holder checking. 3D tooling has also seen many usability improvements such as 3D tool icons in tool lists, stop-on-contact functionality when mating insert to holder, and auto-populating compensation point when defining 3D tools.

Job Preparation and Setup

Mastercam 2020 increases efficiency and reduces job setup time and the preparation needed for part machining and programming. This includes the ability to filter inserts and holders by attributes as well as the ability to track associativity. Chaining enhancements include an improved Chaining dialog box layout for Wireframe and Solids mode, and chain display and behavior improvements.

Validation

With improvements to toolpath and machine simulation, toolpath graphics, and other verification and analysis tools, Mastercam 2020 provides greater programming assurance and allows for better, more informed decisions before a job is run. These improvements include the go to home position on tool plane change which moves the tool to a home position between operations when there is a plane change. Rotary axis positioning allows you to simulate and visualize multiaxis movement of the machine tool, while Skip Drill Cycle Pecking improves cycle time estimates.

Partnership Implementation

Save time, reduce errors, and gain access to the latest innovative partnerships offered through Mastercam. Mastercam has teamed up with some of the manufacturing industry’s top players, providing a wider variety of new software tools, shop-proven hardware, powerful learning tools, and much more.

To see more of the powerful tools available in the Mastercam 2020 Router release, please stop by the booth at AWFS or visit www.mastercam.com/solutions/router.