Tolland, Conn. – From accepting and programming any CAD file to Dynamic Motion™ roughing and precision finishing, Mastercam 2020 Lathe gives you a variety of options to turn all your parts exactly as you need them. Mastercam 2020 Lathe features new 3D tooling, filters for inserts and holders, improved chuck jaw definitions, and much more.

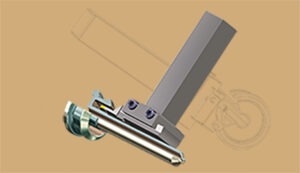

3D Tooling

3D Tooling has many usability improvements, such as the new 3D tool icons in the tool lists to help distinguish between 3D and non-3D tools in the Lathe Tool Manager, and the new stop-on-contact functionality when mating insert to holder. Mastercam 2020 allows you to build inserts using the new Insert Designer function panel, as well as holders using the new Holder Designer panel.

Filters for Inserts and Holders

Mastercam 2020 Lathe lets users filter inserts and holders by attributes by selecting the attributes they are looking for. Only items that match that criteria will display in the Tool Manager.

Improved Chuck Jaw Definitions

Parametric jaw definitions are now more powerful and flexible with Mastercam 2020 Lathe. A few enhancements include support for pie-shaped jaws in additional to rectangular-shaped jaws, ability to change the mounting orientation with easily reversible steps, as well as a live preview showing the overall shape of the jaws and total dimensions. In previous versions, you were limited to a fixed set of seven possible reference positions to identify the location of where the jaws clamp the part. Now, you can select any point on the profile.

Also available in the Mastercam 2020 Lathe is:

• Auto-populating compensation point when defining 3D tools.

• New tabs to display library inserts and holders in the Lathe Tool Manager.

• Chuck jaw improvements such the ability to define as many steps as required, set the dimensions of each jaw individually, and add a radius to the step.

For more information on Mastercam Lathe, please visit https://www.mastercam.com/solutions/lathe/.