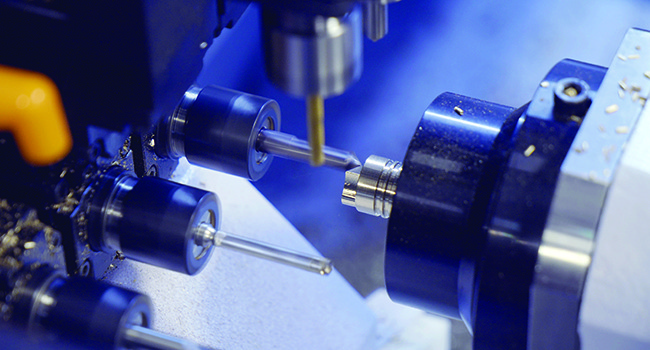

Swiss machining is similar to conventional turning on a lathe, but the difference lies in how the stock material is moved and supported. A standard lathe with a fixed headstock is designed only to spin the stock material; aside from its rotation, the material is held perfectly still in its collet. The cutting tool is the part that moves along the material to make the proper cuts. In Swiss machining, the material passes through a sliding headstock and a guide bushing, sliding down the longitudinal axis of the machine. So why is this difference important?

History of Swiss Style Lathes

Although Swiss machining has only become a buzz term in the past decade or so, it was actually developed in Switzerland in the 1870s as a solution for the watch-making industry. Inventor Jakob Schweizer created a lathe with a sliding headstock in an effort to find a more efficient way to produce the thin parts he needed for his watches. His contraption is one of the reasons that the world’s most famous watchmaker, Rolex, is from Switzerland. Within a decade of Schweizer’s creation of the Swiss machine, his idea was being mass-produced and spreading over the globe. Today’s Swiss machines look very different than the first machines that were made almost 150 years ago, but their niche remains the same: machining small, thin parts that no other machine can.

Where are Swiss Machines Used?

Imagine holding a long, thin stick between your hands. If you were to rub your hands together quickly to make the stick spin, the part of the stick closest to your hands would be most stable, but the end of the stick wouldn’t be so much spinning on its axis – as whipping around in a circle. This concept is what makes Swiss machines so useful. Long, narrow parts are predisposed to wobbling more and more towards the end that is not held by the machine because of their centripetal force. In a Swiss machine, the guide bushing eliminates the problems this can cause by supporting the material as close to the cutting tool as safely possible (as close as 0.020”–0.080”). Even at aggressive speeds, parts are unlikely to deflect or be gouged. While it is recommended to use a Swiss machine for any part that has a 3:1 length to width ratio or greater, most Swiss machines can cut parts with up to a 20:1 length to width ratio without issue.

Historically, the medical industry has been the dominant user of Swiss machining. Bone screws especially were difficult – if not impossible – to machine to specifications with standard lathes. The screws present a number of machining complications: their length to width ratios are often very high; they are mostly machined from titanium, which is known for its poor heat conductivity and likelihood to create problems with chip load; and their tolerances are extremely tight so that the patient is both safe and comfortable. Modern bone screws even have multi-start threads, where two or more threads go around the screw at least one full turn, increasing the complexity of the overall part. Taken altogether, it becomes clear that Swiss machining is the best option for machining situations like this.

These days, almost every manufacturing industry uses Swiss machining. As the tolerances on customer parts become tighter and tighter and the margin for profitability becomes slimmer and slimmer, Swiss machining becomes increasingly valuable. Not only does it make a greater range of part production possible, it also heightens the quality of existing parts while reducing their cycle times. Any reputable, high-production, modern aerospace, oil and gas, automotive, defense, or electronics shop will have a Swiss machine.

What Materials Are Used in Swiss Machining?

Swiss machines offer a distinct advantage over conventional lathes in the range of materials that they can cut safely. Most often, Swiss parts are machined from common materials like aluminum, titanium, and stainless steel. However, many manufacturers use nickel alloys, carbon steel, bronze, brass, and copper. Swiss machines can even cut plastics, often as a cost-effective and more precise alternative to injection molding for creating prototypes. Virtually any rigid plastic can be used, but the most common are Polycarbonate and Teflon.

Basic Design of Swiss Lathes

The two features that make a lathe a standard Swiss lathe are the guide bushing and the sliding headstock. The bar stock is turned rapidly while advancing through the guide bushing. This bushing provides the support necessary to eliminate deflection. The sliding headstock is what holds the stock material and slides along the guideways on the machine’s bed. The tool remains stationary and cuts close to where the material is held.

By keeping a stationary cutting tool parked rigidly 2mm away from stock and allowing stock to pass through the tool, Swiss users can cut very long, small diameters. A key to performing this lies in the condition of the stock. When utilizing a guide bushing, it is imperative to use ground stock or SMQ (Screw Machine Quality) stock. Remember, you cannot turn a round part with material that is out of round. Guide bushing diameters are typically ground to +/- .0002 or better. It is recommended that if you are running .4375 ground stock you should use a .4375 diameter guide bushing.

The newest Swiss machines can be run in Hybrid or Chucker mode, in which the guide bushing is removed from the machine. There are also machines with a turret or gag slide that move tools into stationary stock, but the vast majority of Swiss machines do still have guide bushings and move the stock to the tool. In any Swiss machine, the turning tool maintains a constant distance from the point of support to minimize deflection.

Benefits of Swiss Machines

A Swiss machine can make the difference between a just-profitable machining shop and an industry-leading shop. Here’s how:

- Fewer set-ups and operations for parts with milled and turned features.

- Higher quality surface finishes.

- Faster machining speeds and shorter lead times.

- Reduced chatter and deflection for long, narrow parts.

- Tighter tolerances.

- Wider variety of materials that can be used.

Ready to Try Swiss?

Good news for existing Mastercam users: you no longer need an additional software package to unlock all of your Swiss machine’s potential. Mastercam Swiss Machining Solutions are available for Mill and Lathe customers and come with optimized post processors designed to work with almost all Swiss machine brands. Want to try Mastercam’s Swiss Solutions as a new customer? Connect with your local Reseller here.