In part one of this blog series, we discussed what Mastercam Add-Ons are (specialized aftermarket software kits that work within the Mastercam interface) and covered four of the most commonly used Add-Ons: Multiaxis, Productivity+, Port Expert, and Mastercam Art. This second blog in the series will cover five more popular Add-Ons and how to use them.

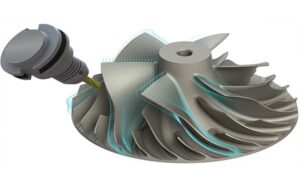

5-Axis Curve Machining

This particular Add-On is considered a great starting point for entering into the multiaxis world. It pairs with almost any 5-axis machine and equips them with predefined, tested cutting approaches. 5-Axis Curve Machining’s hallmarks are logical tool motion, smooth transitions, and strong vector control. In a word, it is safe. This is essential where parts require more complex toolpaths and higher tool axis control: any multiaxis part.

5-Axis Curve Machining operates by optimizing how the tool engages with the stock material. This means that the toolpath is controlled and safe even as the tool travels over dynamic or complex curves. Parts machined with this Add-On will show superior surface finishes, and their cycle times will be greatly decreased.

APlus

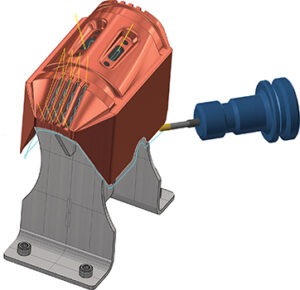

While Mastercam’s focus is predominantly on subtractive machining – in which material is cut away to “reveal” the part – the Add-On Mastercam Aplus® by CAMufacturing Solutions is an additive manufacturing kit. It lends the familiar Mastercam interface to direct energy deposition (DED) 3D printing. This allows users to program, backplot, and simulate the exact same way they would with a machining program. Additive material can be cut with familiar Mastercam toolpaths, opening possibilities for true hybrid machining!

APlus is perfect for R&D prototyping, repair work, and even standard production. Additive manufacturing is often the go-to for quickly creating and testing prototypes, and all the better if the approved prototype can be machined within the same software from which it was printed. APlus is an exceptional product for educational institutes and the aerospace, defense, and energy industries.

Blade Expert

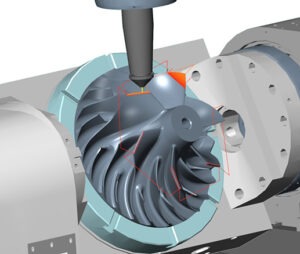

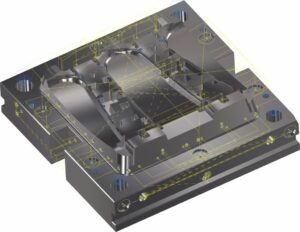

This multiaxis Add-On helps with bladed parts: i.e., manufacturing compressor wheels, impellers, propellers, turbine blades, and bladed discs (blisks). These parts are notoriously difficult to program with standard approaches. Most often, they require involved 5-axis methods with multiple steps. Blade Expert automates the process. It divides machining into distinct sections – removing material between blades, finishing the blades and splitters, finishing the floor, and finishing the fillets – and then applies specialized, stock-aware cutting approaches.

Blade Expert is most commonly used in 5-axis applications for the automotive, aerospace, and marine industries. It is especially useful for manufacturing multi-bladed parts for air or gas handling, though its applications are far-reaching. Its learning curve is gentle, as it functions within the same interface as all Mastercam multiaxis toolpaths. Users will be able to start using Blade Expert with little to no training.

ProDrill

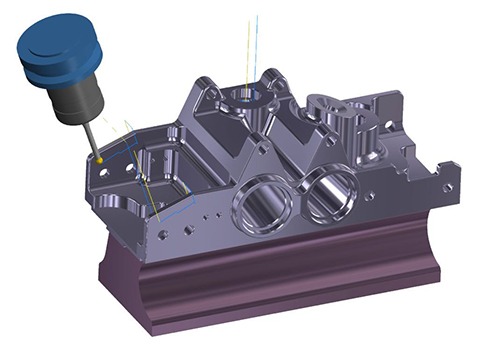

ProDrill is designed for streamlining the drilling routines for surface and solid models with complex, varied, or numerous holes. It is another Add-On that can be whatever the user needs. Let the kit identify drill forms and apply drilling strategies automatically, or customize every phase of the process to suit your own style of machining. After applying toolpaths, ProDrill boosts efficiency during cutting by optimizing the tool plane rotation and minimizing unnecessary tool motion.

Moldmakers, aerospace manufacturers, and job shops are historically the most common users of ProDrill, though any high-volume shop can benefit from its tools. This Add-On excels wherever there is simple drilling, counter-boring, reaming and boring, chamfering and counter-sinking, threading and tapping, circle milling, or custom drill forms. ProDrill creates predefined, repeatable drilling operations that decimate cycle times on high-production runs.

File Translators

File Translators give users the freedom to bid virtually any CAD file a customer may create. The importers work within Mastercam to bring the original file into a workable model, with no data lost.

Importers can open:

- Alibre Design

- AutoCAD®

- Autodesk® Inventor™

- CATIA™

- Creo®

- KeyCreator®

- Rhino

- Siemens NX™

- SOLIDWORKS®

- SolidEdge

- SpaceClaim®

- IGES (Initial Graphics Exchange Specification)

- STEP (Standard for the Exchange of Product Data)

- STL (Stereolithography)

- VDA (Verband der Automobilindustrie)

- ACIS

- Parasolid®

After importing the original file, users can continue their modelling and editing within Mastercam’s own robust CAD platform. The resulting file will then work seamlessly within the corresponding Mastercam CAM interface for toolpathing.

The Next Step

If there is a common but specific style of part machining, there is probably a Mastercam Add-On to help with it. If any of these have interested you – or you’re wondering if there is one that might fit your shop – reach out to your certified local Mastercam Reseller. Their applications engineers and technical experts will help guide you through your choices and even through installation.