At Mastercam, innovation begins with listening. That is why we are transitioning from an annual to a semi-annual release schedule, reflecting our commitment to delivering continuous value and responding more effectively to the evolving needs of modern manufacturing.

Every feature in the second release of Mastercam 2026 is packed with features designed to accelerate workflows, improve accuracy, and simplify complex machining tasks—so you can focus on what matters most: delivering exceptional machining results.

Mastercam 2026.R2: New Features and Enhancements

Manufacturing is evolving at lightning speed. Mastercam 2026.R2 empowers you to stay ahead with tools that combine speed, intelligence, and flexibility, giving you the competitive edge your shop needs.

Here is a closer look at the features to get excited for with Mastercam 2026.R2:

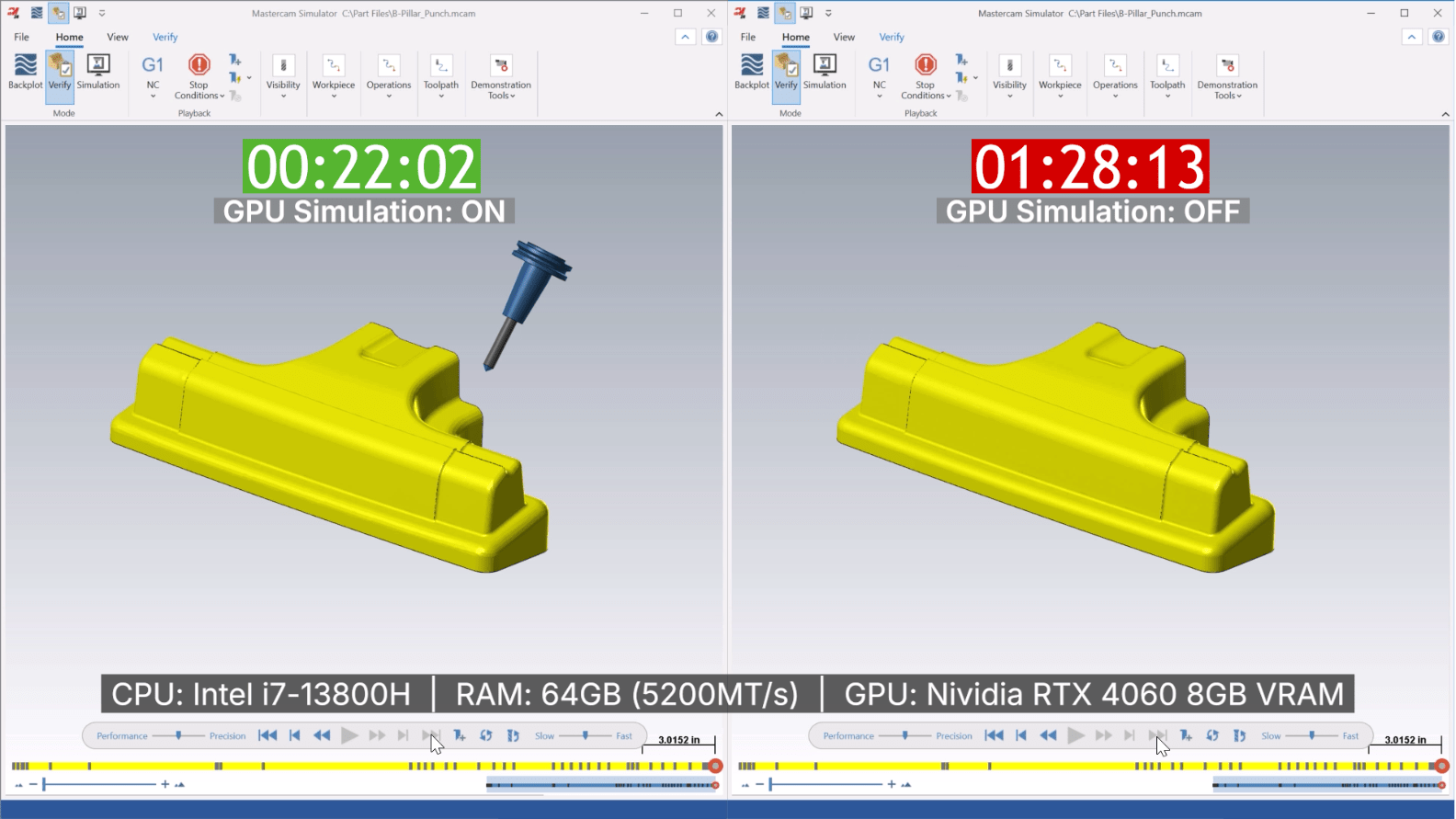

GPU Simulation: Speed Meets Accuracy

Simulation is critical for verifying toolpaths and avoiding costly mistakes. With GPU-powered simulation, you can experience up to 10 times faster processing compared to traditional CPU-based methods.

This means no more compromising on resolution or waiting for results, just accurate, high-quality simulations when you need them most. Faster simulations allow for quicker iterations, better optimization, and more confidence in your machining process, ensuring that every part meets your exacting standards.

Mastercam Copilot: Your Intelligent CAM Assistant

The future of programming is voice-driven and intuitive, and Mastercam Copilot is leading the way. Copilot enhancements make your workflow more efficient and user-friendly. You can now edit feed rates and spindle speeds instantly, create machine groups and operations with simple commands, and even activate hands-free programming with Active Listening Mode by saying “Copilot.”

Video scanning capabilities allow Copilot to pull data from tutorial videos for instant answers, reducing repetitive tasks and accelerate programming.

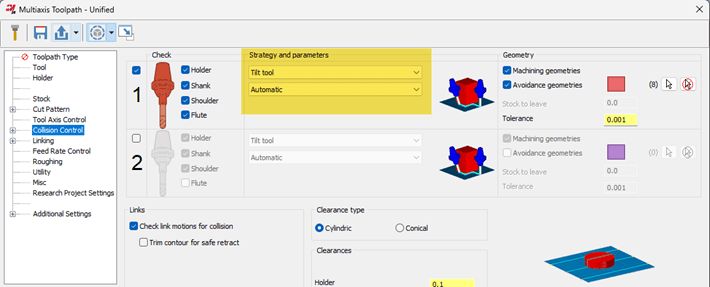

Multiaxis Advancements: Complex Made Simple

For shops pushing the limits of precision, Mastercam 2026.R2 delivers significant multiaxis improvements. Automatic tilting with bullnose endmills simplifies collision-free 5-axis motion, while enhancements to 4-axis Swarf milling improve accuracy for cylindrical and complex parts.

Automatic linking clearance introduces smarter clearance plane calculations for safer, faster toolpaths, and optimized level-based ordering reduces cycle times by sequencing toolpaths more efficiently. These advancements streamline multiaxis programming, reduce setup time, and improve part quality—helping you tackle even the most challenging geometries with confidence.

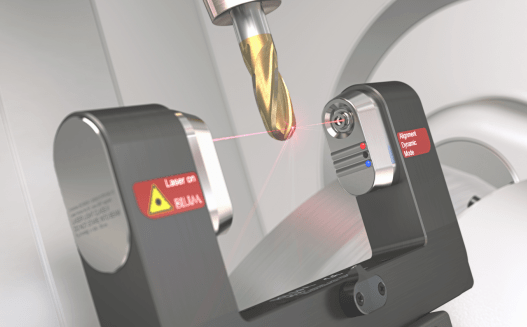

Probing Upgrade: Blum Digilog Setter Support

Mastercam 2026.R2 also introduces support for Blum laser tool setters across major CNC controls, including Fanuc, Siemens, Okuma, Heidenhain, Mazak, and Makino. This integration allows users to output tool setting macros directly from Mastercam, eliminating manual edits and streamlining workflows. Tool height offsets and length offsets are managed within the application, ensuring accurate tool setup, wear checks, and breakage detection; all without relying on supplemental applications.

The Bottom Line

From GPU simulation that accelerates verification to Copilot automation that simplifies programming, and from advanced multiaxis strategies to probing upgrades that streamline setup, this release is designed to help you deliver exceptional results faster and smarter.