What happens when a festive idea meets cutting-edge CAM technology?

From Concept to Creation

What started as a simple holiday concept quickly became a full-blown technical challenge: create a gift complete with an organically sculpted bow and removable lid, all without an existing CAD model.

The design needed to be free flowing, but still machinable, all while demonstrating cutting-edge CAM capabilities. This was not just about making something seasonal; it was about proving what is possible with advanced surfacing, multi-axis machining, and next-generation toolpaths.

Building the Gift from the Ground Up

Mastercam Applications Engineer, Tom Minor, started from scratch, modeling the present starting from a blank screen in Mastercam.

To keep the process simple, he used “historyless modeling” and tracked the design progression using groups in Mastercam’s new and improved Levels Manager. This enabled quick iterations, while preserving each iteration in case of mistakes.

How We Made It Happen

- Setups: Five for each part, including machining, anodizing, and re-machining.

- Fixtures: One set of custom soft jaws for each part.

- Toolpaths: 70 were used for the lid and bow and 51 for the box. 15 toolpaths were used for one set of soft jaws and 11 for the other set.

- Cycle Times: Approximately 1 hour and 20 minutes for the box and 3 hours and 39 minutes for the lid and bow.

- Efficiency gains came from OptiRough, reduced shank tools, and bull mills. In the end, Minor transformed two aluminum blocks weighing 9.4 lbs. into two parts weighing 1.9 lbs. total masterpiece, removing about 7.5 lbs. of material.

- The bell on the bow was modeled in Mastercam, saved as an STL, and 3D printed; showing that Mastercam excels at both subtractive and additive manufacturing.

Sculpting the Perfect Bow

Organic shapes are notoriously tricky in engineering software, but our first-class surfacing tools made it possible. Using a combination of Net Surface, Power Surface, Silhouette Boundary, wireframe projection, and spline guide curves; Tom sculpted smooth, flowing geometry—which blended perfectly on the final machined part.

Innovation In Action

This project was not just about aesthetics; it was proving ground for new technology utilizing several new features and updates from our upcoming Mastercam 2026 R2 release.

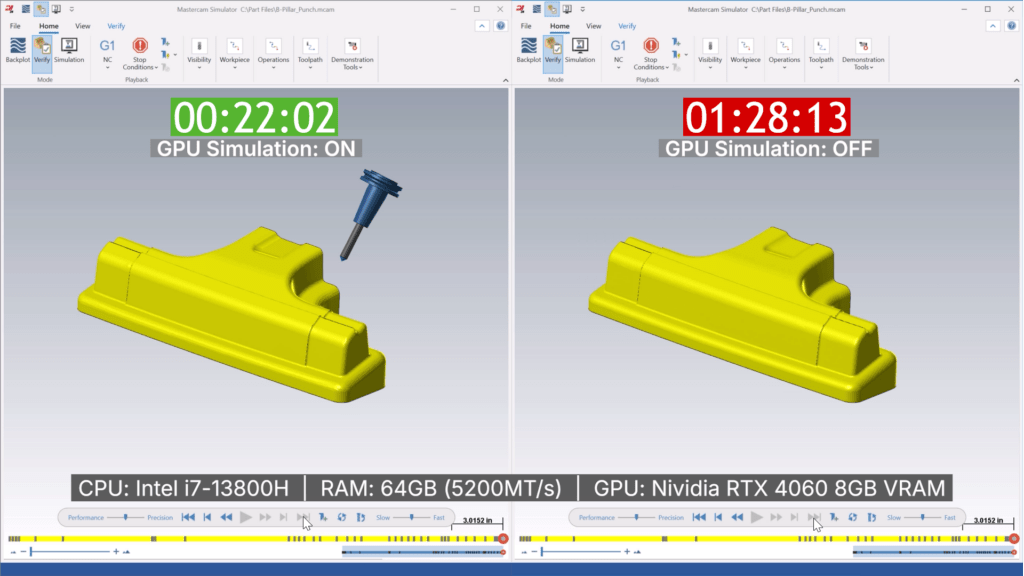

- GPU Simulation: Nearly instantaneous simulation cuts programming time dramatically. It utilizes the Random Access Memory available on the Graphics Processing Unit to accelerate simulation as much as 10x.

- In our test:

- GPU OFF: 203 seconds

- GPU ON: 49 seconds

That’s about a 30% reduction in programming time on a system with only 8GB of VRAM. With 12GB or more, the gains become even more impressive, and because the effect is nonlinear, full-project simulations could easily reach 5–10x faster speeds.

- Soon-to-be-Released Toolpaths: A streamlined interface that reduces cognitive load compared to traditional methods.

- Levels and Planes Manager: Incremental usability improvements based on hands-on feedback. This project is a perfect example of where we “unwrapped” some new enhancements.

Deburr Insights You Can Use

We explored both 3-Axis and 5-Axis deburring on this project.

- 5-Axis: Ideal for complex parts but increases machine wear.

- 3-Axis: Delivers higher rigidity and surface quality but requires more individual toolpaths.

Note: Mastercam 3-Axis Deburr is now free with a maintained Mastercam CONNECT plan (no Multiaxis license required)! Explore all the benefits of Mastercam CONNECT today!

What We Learned

From aluminum gifts to advanced CAM applications, this project shows what happens when we say: Challenge Accepted.

The highlights from this project include:

- Practical insights into GPU simulation and Multiaxis deburring.

- Mastercam Probing for setting offsets and in process inspection.

- Advanced CAD modeling strategies for complex designs.

- Efficient programming workflows with measurable time savings.

- Real-world validation of new Mastercam features.

🎁 Want to Know What is Inside the Present?

Follow us on our social channels for the big reveal soon and get ready for brand new Mastercam release, launching this February.

From all of us at Mastercam – Happy Holidays!