In most small-to-medium machine shops, the people doing the quoting and CAM programming are also your most experienced machinists. They are the ones who know the machines, understand the materials, and can look at a part and immediately start thinking about how to make it. While their expertise is invaluable, much of their time is consumed by tasks that don’t require that level of skill. Pulling dimensions off PDF drawings, tracking down the right STEP file, building out routine toolpaths for straightforward parts, estimating cycle times from scratch every time a new RFQ comes in.

It’s not that any one of those tasks is a problem on its own. It’s that they add up, and they pull your best people away from the work that actually needs their skills.

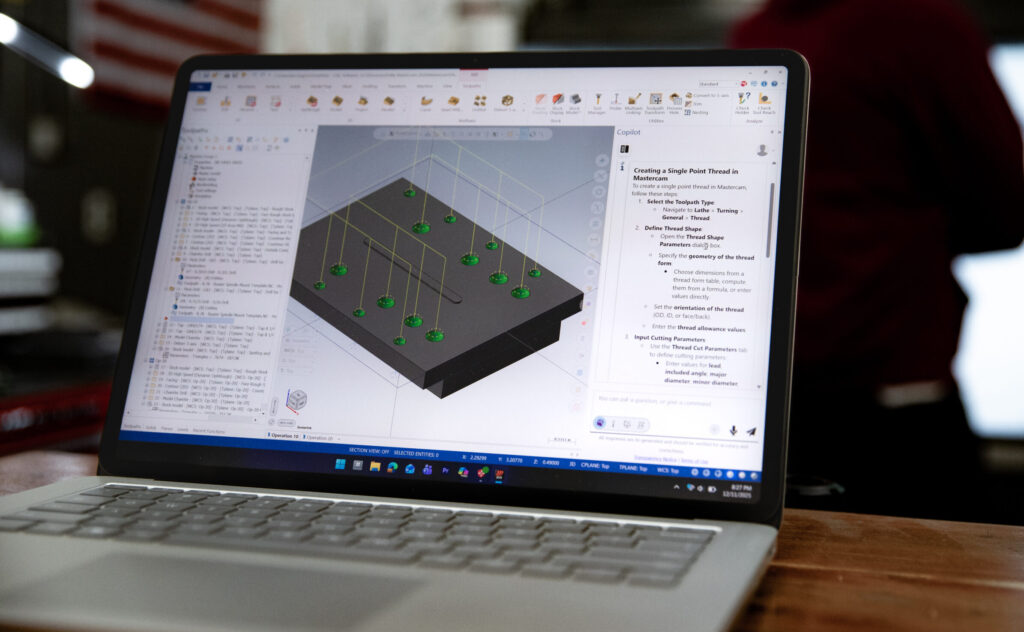

That’s the gap the Mastercam + up2parts integration is designed to address.

What up2parts Actually Does

up2parts is a cloud-based AI platform built specifically for simplifying manufacturing workflows. It was developed in Germany, spun out of an actual production shop (BAM GmbH), and is backed by Sandvik, DMG MORI, and Schaeffler Group. It’s not a general-purpose AI tool adapted for manufacturing—it was built from the ground up for this industry.

The platform covers several connected steps in the workflow, starting with the work that happens before a part ever gets programmed.

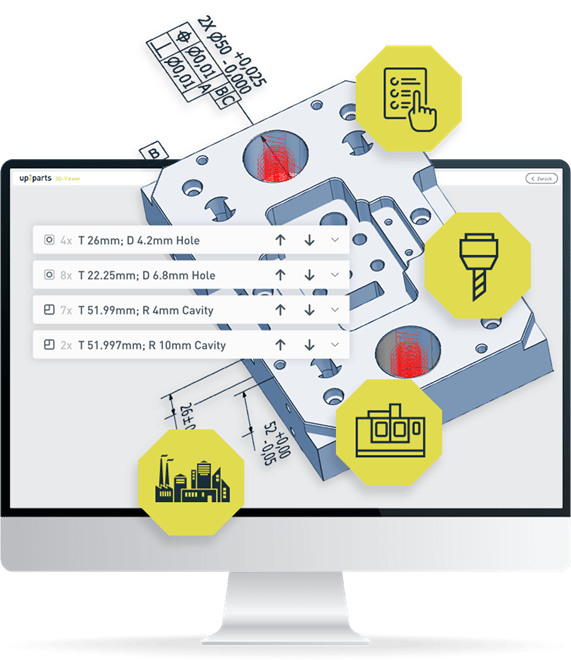

Feature recognition and analysis. When you upload a 3D model and PDF drawing, up2parts analyzes both and automatically identifies part features—holes, pockets, threads, surfaces. It also reads Product Manufacturing Information (PMI) like dimensions, tolerances, and surface finishes from the 2D drawing and maps them directly onto the 3D model, creating a fully toleranced model ready for downstream automation. That step alone eliminates a lot of the manual cross-referencing between files that slows down quoting and programming.

Design for manufacturability (DFM) analysis. Before work preparation even begins, up2parts flags potential production challenges—thin-walled elements, tight tolerances, features that could cause issues on the shop floor. Catching these early means fewer surprises later and more realistic estimates upfront.

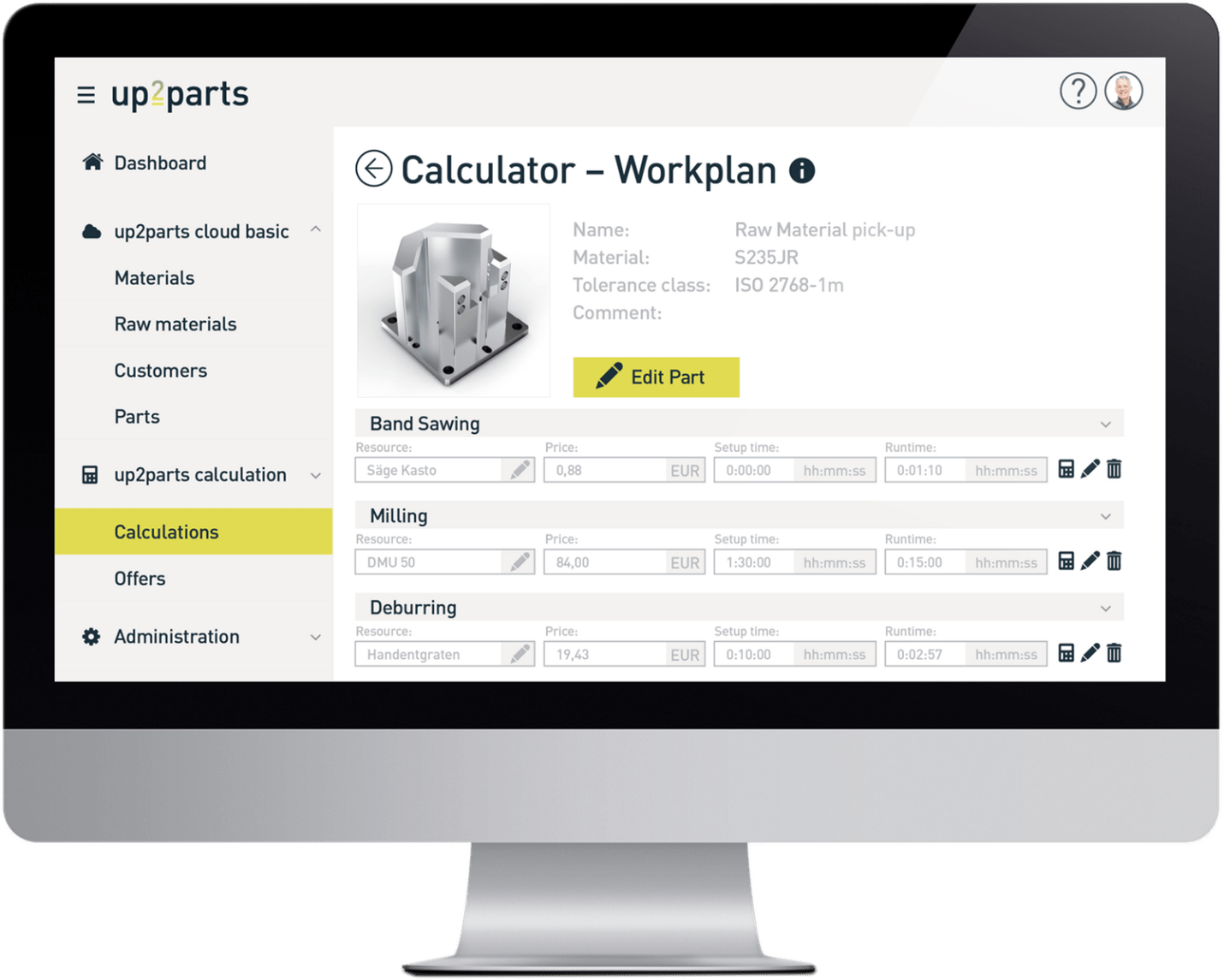

Work plans and cost estimation. Based on the geometry and your shop’s specific manufacturing knowledge, up2parts generates production work plans and automated cycle time estimates. These aren’t generic calculations—the system factors in your equipment, your processes, and your historical data. The result is more consistent, data-driven estimates that don’t depend on which programmer happens to be doing the quoting that day.

Job comparison. One of the more practical features is the ability to automatically search your database for similar past jobs. If you’ve already quoted and programmed something close to what just came in, up2parts finds it—reducing the need to start from scratch on quoting and programming every time.

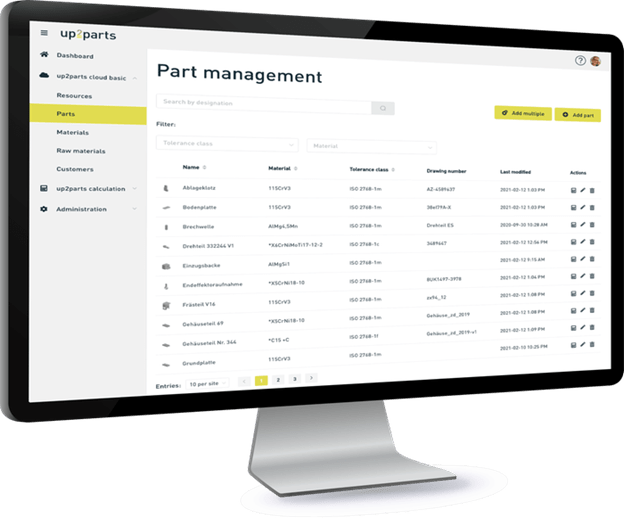

Centralized file management. The up2parts Cockpit gives your team one place to find CAD files, drawings, PMI data, CAM programs, and tool data. It’s cloud-based, so it’s accessible across departments and even directly on machine tool controls—without needing to set up a shop-wide network for centralization. It’s a straightforward improvement, but shops that have been running on shared drives and tribal knowledge notice the difference immediately.

Where up2parts Fits

For small-to-medium shops that can’t justify the cost and complexity of premium ERP and MES solutions, up2parts offers a practical path to the kind of automation and centralization that used to be out of reach. It’s designed for shops where programmers are stretched thin and need to focus their expertise on the jobs that actually demand it.

What’s Ahead

The up2parts team is actively developing more advanced capabilities, and the integration with Mastercam will continue to deepen over time. As the platform’s AI learns from more data and more shops, the toolset will only become more capable. It’s worth keeping an eye on as it matures.

See It in Action!

We are hosting a live webinar on February 25th where we will walk through the Mastercam + up2parts integration in a real workflow—from uploading a part to generating a quote and CAM toolpaths. It is a good opportunity to see how the platform handles actual jobs and ask questions about how it would fit into your shop’s process.

up2parts will initially be available in the UK, Sweden, Norway, and Denmark regions.

Register here to save your spot.