What is injection molding?

Injection mold making is the go-to method for mass-producing plastic parts. The process is streamlined to maximize cost savings and part production. First, pelletized material is placed into a heated container to turn molten. It is mixed with a helical screw to maintain a smooth consistency and to speed up the heating process. The liquid is then pumped – or injected – with a plunger into a premade mold, which shapes the material into the desired form as it cools and hardens. Sometimes another component is inserted into the mold cavity as the material cools in a process called insert molding. This adds another level of complexity to the mold. Most often, injection molding is done with thermoplastics, a plastic made of polymer resins designed to soften or liquify when heated. Less commonly, thermosetting polymer, metals, and glasses are used.

What are the benefits of injection mold making?

Injection mold making is the best way to mass-produce plastic products and is the predominant method of doing so in the U.S. Thermoplastics are incredibly versatile and cost-effective. They make everything from common household items like cups and combs to highly specialized automotive components. Injection molding is most efficient for high volume, low variety shops that produce parts with looser tolerances that might require machining.

What are the applications of CNC machining for injection mold making?

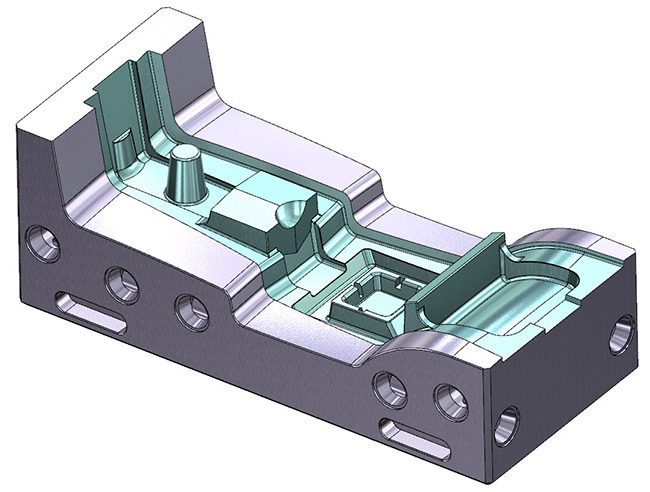

While the tolerances of the finished product may not call for CNC machining, the molds themselves do, especially those with complex inner geometries and contours. CNC machining is the leading production style for mold making. Molds are most commonly machined out of tool steel and stainless steel, but aluminum is also used occasionally. Aluminum doesn’t hold up to the wear and tear of injection molding as well as steel, but it is an inexpensive alternative for small batches of injection molded parts.

Steel molds must be able to maintain their exact dimensions and inner contours over the course of thousands or millions of injection cycles, and all the heat and stress associated with them. CNC machining makes machining these metals to the desired tolerances simple.

Less frequently, CNC machining is used for finishing injection molded parts. During the molding process, it is common for the part to acquire parting lines, gate marks, and ejector pin divots. Once cooled and hardened, the parts can be machined to remove these blemishes. After machining, the surface finishes will be much better, which can be important for parts that are valued on aesthetics.

Mastercam CNC machining capabilities for injection molding

Mastercam CAD/CAM software has evolved over decades to be the perfect tool for designing and machining molds.

- Wire EDM solutions provide advanced, specialized toolpaths for the mold making industry.

- Intuitive CAD software give users the ability to import, modify, or create almost any geometry.

- Programming 4- and 5-axis machines to cut complex shapes without needing multiple setups is easy with Multiaxis.

- Accelerated Finishing and Deburr toolpaths cut bench-time significantly.

Learn More

Ready to bring Mastercam into your mold making shop? Contact your local Reseller here.