CNC machinists are one of the most in-demand workers in the United States and even worldwide. Why? Partly because no one has any clue what a CNC machinist does. (If that’s you, don’t worry: CNC machinists program, setup, and operate high-precision computerized machines that use a subtractive process to create parts that go into almost any household item.) Every vehicle you’ve ridden in, building you’ve walked past, or computer or phone you’ve used today has machined parts in it. It’s no wonder why the CNC machining market is growing so rapidly. In this blog, we will go over the top three reasons that joining this booming industry is a good idea.

Financial stability and job security

According to Education Data Initiative, the average college student graduating in 2023 will have about $37,574 of student debt. ZipRecruiter reports that the average salary for a recent graduate is $36,536 – or about $17.57 per hour. That math is not particularly inspiring. Now consider that a high school student from a technical school could walk out the door the day they graduate and start a job as a CNC machinist making $20 per hour with zero debt. Because CNC machinists are in such high demand, shops are willing to pay them well to keep them around.

CNC machining is one of the most secure careers to have. The industry is only going to grow in the next 25 years, so machinists don’t have to worry about losing their jobs when the economy fluctuates. During COVID, while most people were sent home for lockdown, CNC machinists were working overtime to produce essential parts for personal protective equipment and medical devices. This job security also means that CNC machinists can leave any shop that isn’t the absolute best fit for them and easily find another position, usually without even relocating. In fact, people well into their 30s and 40s are changing fields to become CNC machinists because of the demand.

Matthew Siehl, Content Developer, Mastercam says, “I graduated from the Piscataway Vocational and Technical High School (currently known as Piscataway Magnet School). As a 17/18-year-old kid I was making $15 an hour the day after graduating; I felt like I was on top of the world. From there, not having to have a college degree allowed me to move on to other shops and learn as I progressed. I was always able to find a new shop to work in if things were not a good fit or working out.”

Opportunities to be creative and to solve problems

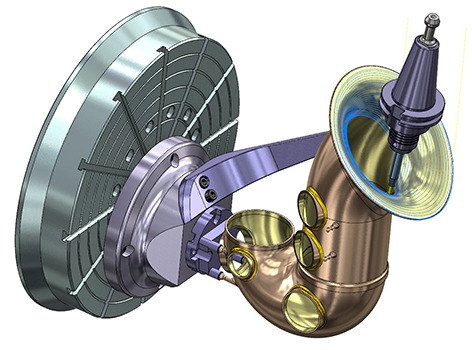

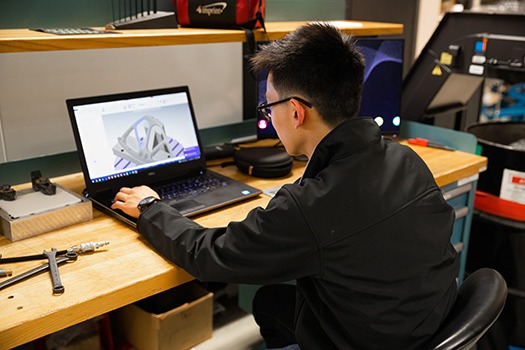

Manufacturing and CNC machining in particular are perfect career routes for people who hate to sit still and do the same thing day in and day out. It’s no desk job. Every day, CNC machinists are moving around the shop, fixturing parts, and running the high-speed machines that create precision parts of all shapes and sizes. As they run their machines, CNC machinists get to see firsthand the results of their effort in the form of a state-of-the-art machined part. It’s something that very few people can do.

Clint Smith, Sr. Education Market Specialist, Mastercam says, “I attended Vincennes University for Injection Molding and Tool and Die. Early on, I was drawn to the idea of good pay. But then I came to love the process of creating things with high precision. There is a lot of pride to be had when doing something that most people do not have the skills or knowledge to do.”

High growth potential and diverse career opportunities

Shop owners all over the country will tell you the same thing: once they have a good CNC machinist, they’ll do everything they can to keep them. Promotions stay internal. Companies pay for continued training. Salaries and benefits are kept competitive. The singular factor that limits the growth of most machining shops is that they simply can’t find enough skilled workers to operate their machines. Once they do, though, shops that value their machinists make sure that their employees grow along with them.

If, for whatever reason, a CNC machinist wants to grow elsewhere, there are thousands of shops with openings across dozens of sectors where their skills are needed. A machinist at a shop that makes automobile chassis components is not limited to that field. The basic concepts of CNC machining can be taken anywhere there is a CNC machine. CNC machinist can transfer from an aerospace shop to a medical device manufacturer or a mold and die shop without having to learn an entirely new set of skills. In fact, most do so that they can find their passion within manufacturing.

Ready to learn more?

Read something that piqued your interest in CNC machining? Try visiting Mastercam University, our online, video-based training, where you can learn about the basics of Manufacturing and how to use Mastercam. You can access the free resources that consist of tutorials on topics such as Mastercam Basics or introduce yourself to some Mastercam courses in Mill, Lathe, and more.