The aerospace industry encompasses not only all things aviation and flight, but also aircraft operations in space, and it services the private, commercial, and government defense sectors. In 2019 alone, the industry contributed over $900 billion to the U.S. economy and employed over 2 million people, according to the Aerospace Industries Association. In 2020, however, the industry took the biggest downturn in its history when COVID-19 impacted the global travel demand.

Experts agree that aerospace manufacturing is once again on the upswing, but Deloitte reports that recovery will be uneven between commercial aerospace and defense; travel demands are not forecasted to return to normal until 2024, but most governments have not reduced their defense budgets and are still driving forces in the industry. For both sectors, though, some scheduling delays and minor cost increases are expected as a result of the instability of 2020 and early 2021.

Luckily, aerospace manufacturers are eager to meet the demands of a recovering industry. What will set successful manufacturers apart from the rest will be their production approach. These companies will need to manufacture parts at top speeds to make up for the past year and a half of stymied production, maximize their profit margins by eliminating manufacturing errors and wasted time, and provide the highest quality parts possible.

Why does the aerospace industry use CNC machining?

While CNC machining is not the only manufacturing process used in aerospace, it may well be the most widely used. 3D printing is often used for lightweight components that aren’t crucial to system functions, like the 3D-printed polymer sensor covers for radiation monitors on the International Space System. For engine parts and other critical components, though, the only way to achieve the necessary tolerances is with CNC machining. Otherwise, the parts just would not be precise enough to be safe. Today, every sector within the aerospace industry uses CNC machining. For producing screws and other long, thin parts that must meet specific tolerances, many shops use Swiss machining. For complex parts with odd geometries like the combustion components in modern turbines, many shops use multiaxis machining. There are combinations of 3D printing and CNC machining to get some printed parts to tolerance. CNC machining is almost universal in aerospace, but its applications are as varied as the parts it creates.

What materials are used?

Aerospace was once dominated by low-cost, low-weight aluminum. While it is still used today, more composites and alloys are taking their places as go-to manufacturing materials. Materials of lower weights and higher temperature resistances are needed for engine parts and other components likely to endure high stresses during flight. A modern lean-burn engine can run as hot as 3,800°F (2,100°C) and must be made out of material that can withstand that. Heat-resistant alloys, often nickel and titanium, are becoming more common, along with nonmetal composites like ceramics. However, these materials are more difficult to machine than aluminum and require advanced CAM software to ensure safe machining.

5-axis machining in the aerospace industry

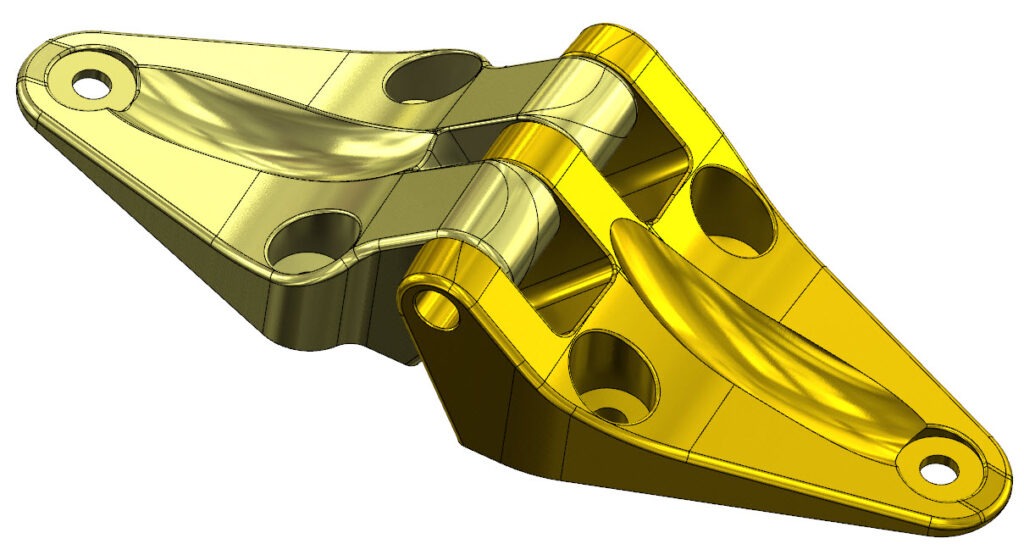

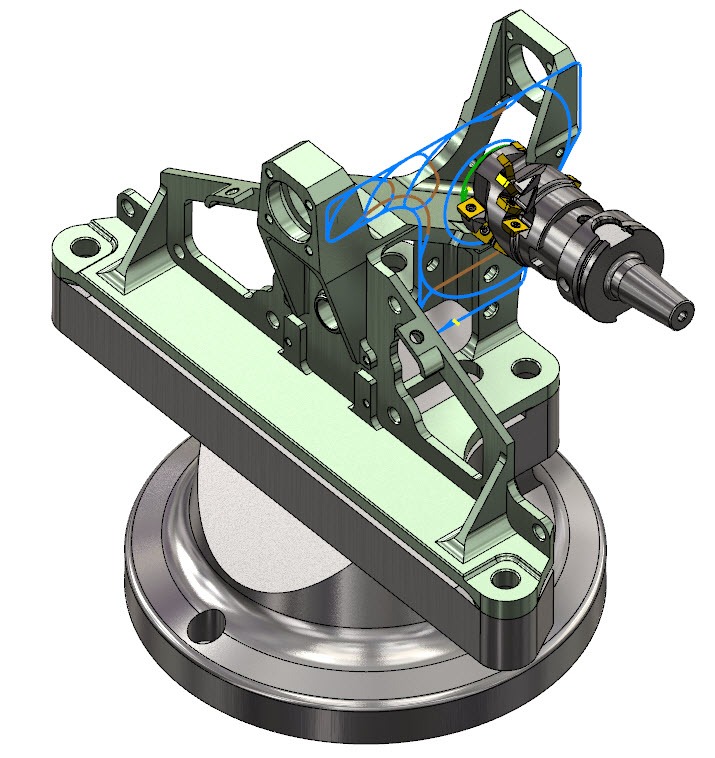

Aerospace parts are most often highly complex. Most have odd geometries that require difficult approaches and sophisticated work-holding solutions. None, under any circumstances, can fail during use but are often made out of frangible or difficult-to-machine materials. Many are relatively large and need machines with huge work envelopes. The best way to solve these problems is by using multiaxis machining, namely 5-axis machining. Any modern, competitive aerospace shop will be using 5-axis machining to produce parts that meet the tolerance and scheduling requirements of customers.

Mastercam aerospace CNC machining capabilities

With 5-axis machining – and aerospace manufacturing in general – comes a level of risk. As parts become more complex, so the opportunity for error grows. With five different axes, for example, there are more chances for machines to self-interfere. This is where a capable CAD/CAM system comes into play. Mastercam CAD/CAM software offers complete solutions specifically tailored to the aerospace industry, like efficient toolpaths that conform to forgings and castings; streamlined, 5-axis cutting, trimming, and drilling; intelligent toolpaths that efficiently target uncut areas; and specialized motion for extended tool life and decreased cutting time. The software also integrates seamlessly with third-party solutions that aid in design and process tracking.

Ready to set yourself up for success in the aerospace manufacturing industry? Download our whitepaper here to get started.