Meet Mastercam 2022. You spoke, and we listened. Since the release of Mastercam 2021, the Mastercam User Experience team has surveyed countless users, conducted usability tests inside and outside of Mastercam headquarters, and spent hours and hours trying to reduce mouse miles. The result is Mastercam 2022—a powerful new release driven largely by customer feedback. Now we invite you to explore the features that you requested—like more advanced roughing in 2D machining and improved workability with meshes—and to find out how the latest version of Mastercam can help you.

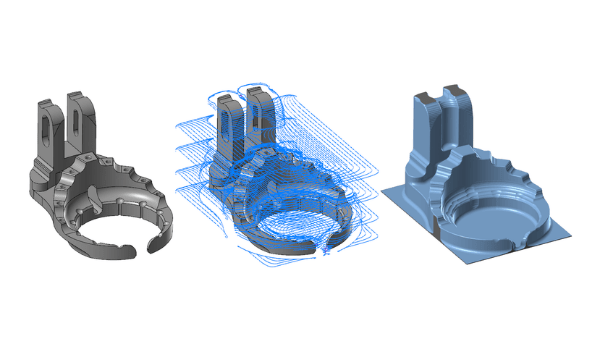

1. OptiRough in Mill and Router

When OptiRough was first introduced in 2010, it was not sold as an add-on; it was given to every Mill 3D user on Maintenance. Since then, the Mastercam development team has collected immense amounts of feedback and has made continuous improvements to the technology. As a result, OptiRough is one of the most well-tested and reviewed toolpaths within Mastercam.

Now, the 3D High Speed Dynamic OptiRough toolpath is available for all Mill and Router product levels, notably bringing this technology to 2D users. With OptiRough, users can rough an entire part with one toolpath rather than multiple individually programmed 2D operations. The collision-aware toolpath relies on Dynamic Motion technology to maximize material removal in the fewest stepdowns possible, eliminate air cuts, and minimize tool and material damage. The secret is in OptiRough’s powerful bidirectional cutting strategy that employs large cut depths to boost material removal, which decimates both programming and machining time.

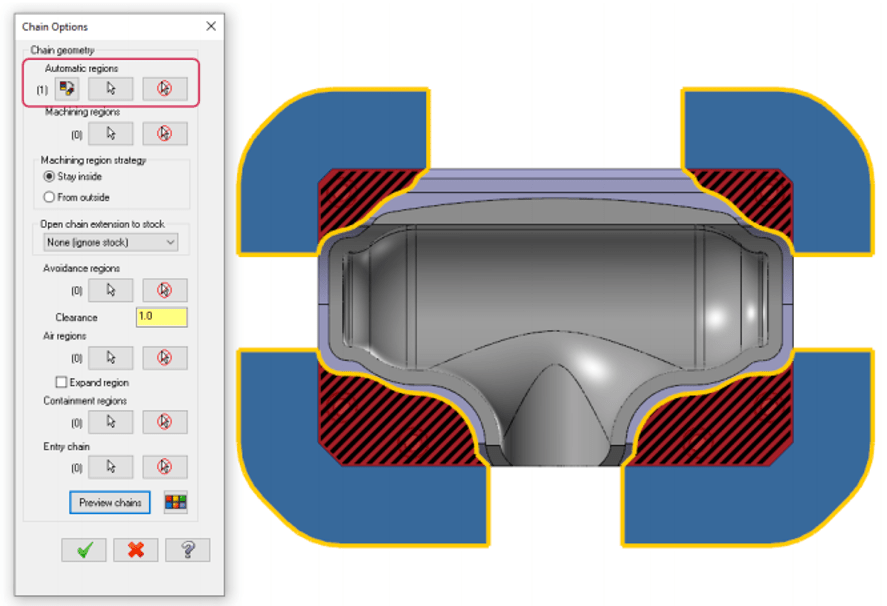

2. Automatic Region Chaining for 2D

When selecting geometry for a 2D Dynamic Mill, Area Mill, or 3D Dynamic Mill toolpath, users can take advantage of the new Automatic regions selection to automatically create Machining, Air, or Avoidance regions based on the selected solid geometry. This saves time by allowing Mastercam to select the geometry itself. You can also convert the selected Automatic regions into Machining, Air, or Avoidance regions by using the Convert automatic regions button in the Chain Options dialog box, the Toolpath Type page, or from the Chain Manager right-click menu.

Automatic region chaining in Mastercam 2022 is completely associative. If any changes occur to a face, the toolpath will at once associate and be ready for updating. With one click, users can create toolpaths that avoid bosses and correctly define space as air or material.

3. Improved Mesh Editing Tools

Rather than having to save a solid or surface to a stereolithography (STL) file and merge it back—a time-consuming process that introduces the opportunity for error—you can now create single mesh entities from other multiple mesh entities, surfaces, solid bodies, or faces.

The following functions now include the ability to interact with mesh entities:

- Analyze Dynamic (on the Home tab): Analyzes a mesh dynamically across its facets.

- Curve Slice by Plane, Curve Slice Along Curve, and Curve at Intersection (on the Wireframe tab): Now supports meshes along with surfaces, solids, and wireframe to create wireframe on meshes to use for other processes. For example, turn scanned data for an intake port into cross-sections that you can use to create lofted surfaces or solids.

- Point Dynamic (on the Wireframe tab): Creates points dynamically on a mesh.

- Line Normal to Point, Line Normal to Grid, and Line Normal Along Chain (on the Wireframe tab): Create normal lines on a mesh to control the tool axis in a multiaxis toolpath.

- Disassemble (on the Model Prep tab): Organizes multiple meshes into a specific plane.

- Change Normal (on the Surfaces tab): Reverses the normal direction of a mesh.

- Project (on the Transform tab): Now supports meshes along with surfaces and solids.

- Geometry Nesting/Toolpath Nesting (on the Transform tab and Toolpaths contextual tabs): Nests meshes to fit parts onto machining surfaces or for additive manufacturing.

- Modify at Intersection (on the Wireframe tab): Breaks, trims, or creates a point where wireframe entities intersect with a mesh.

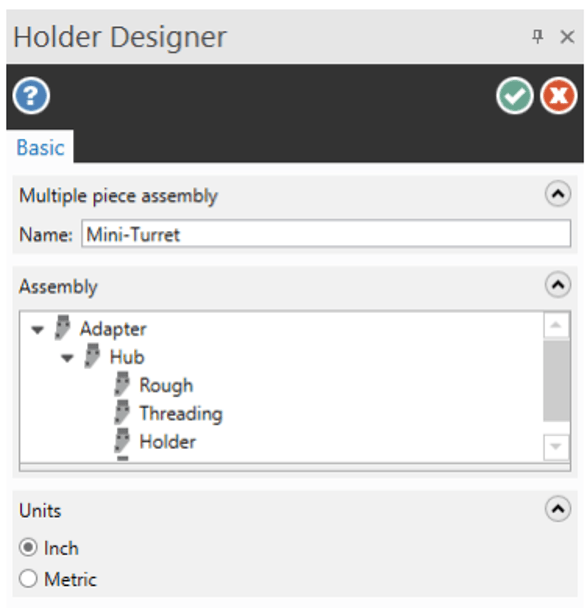

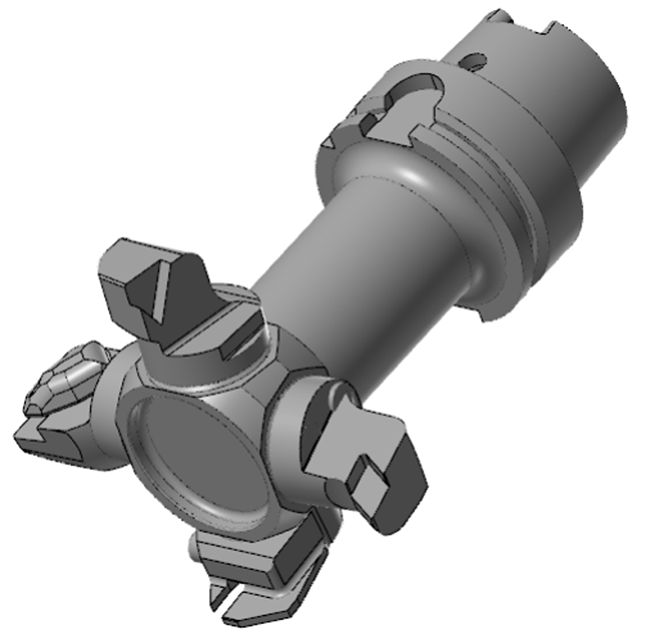

4. Multiple Adapter Support

In Mastercam 2022, users can now define reusable holder assemblies in the Holder Designer, which is accessible through the Lathe Tool Manager Holder tab. The Holder Designer allows users to create collections of adapters, extensions, and holders, and store them as assemblies. Access to the Holder Designer is also available by clicking Select from Library for a holder component, right-clicking in the Browse for Item dialog box, and choosing to create or edit a holder. By creating reusable assemblies of modular components, users can save time and avoid errors. These assemblies can be stored in a library and used for the creation of full 3D Lathe tool assemblies.

5. Multiaxis Unified Toolpath

This new unified toolpath allows users to generate multiaxis toolpath patterns by selecting multiple pieces of input geometry. The toolpath will then automatically choose the best algorithm available to calculate a path, like the best way to morph between two surfaces.

This single toolpath will give users access to all the surface-based toolpaths like Morph, Parallel, Along Curve, and Project, as well as the geodesic toolpath options like Automatic and Guides. There is no longer any need to toggle in between interfaces. You can also add or remove patterns without starting the toolpath over by using one of the four drive patterns: automatic, curves, surfaces, and plane.

Thank you for helping to make Mastercam 2022. These are just a few of the powerful customer-driven changes in this latest version. To find out more, check out whatsnew.mastercam.com.

If you are ready to upgrade to Mastercam 2022 or want to learn more about solutions for more efficient manufacturing, be sure to contact a Mastercam Reseller. Our global network of Mastercam Resellers is available to give you localized knowledge, sales, training, and CAD/CAM software support for your manufacturing needs. Complete our form to find your local Mastercam Reseller.