Venom Outdoors Switches to Mastercam to Save Money and Optimize Production

Venom Outdoors produces fishing lures from start to finish, including their molds. When owner Cory Robinson’s CAD/CAM software for his CNC mill machine was wasting expensive tools, he decided to invest in Mastercam software.

Quick Facts:

- Product Used: Mill

- Industry: Moldmaking

Project Details:

- The Challenge: Removing material quickly to create molds with tight tolerances without sacrificing tool life.

- The Solution: Mastercam, the most widely used CAD/CAM software for machining applications.

- Benefits:

- Network of knowledgeable, experienced Resellers who can introduce and explain new techniques and functions.

- Powerful Multiaxis toolpaths to reduce operations and expand a shop’s capabilities.

- Tool Manager for importing tool libraries from tool manufacturers.

- Advanced simulation tools like Verify and Backplot to highlight errors before they occur.

- Dynamic Motion technology that reduces cycle times without sacrificing tool life or stock material safety.

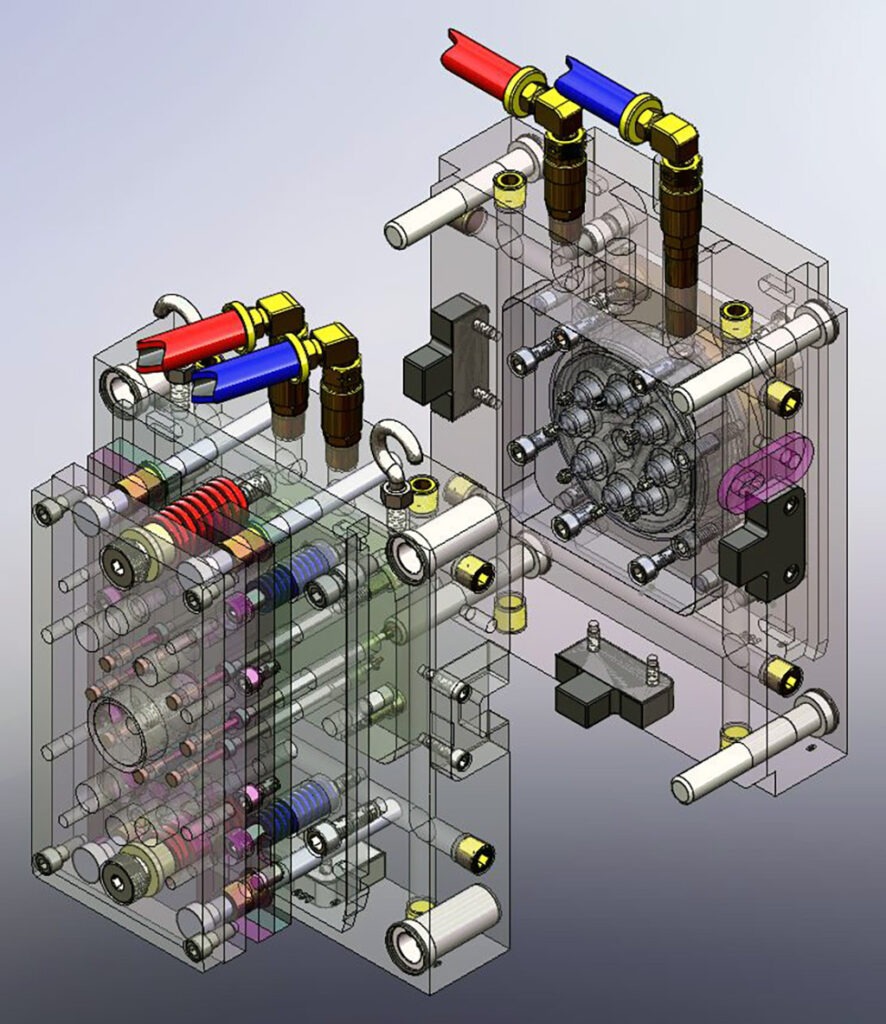

Cory Robinson is the founder and owner of Venom Outdoors, a company that makes cutting-edge fishing products and their molds. Most of the products utilize injection molding, and each product comes with its own unique challenges. “All of the products we design and make are complex and difficult,” said Robinson. Some of the lures are small to begin with—some as light 1/40 oz.—and the tooling may have cavities of different sizes. On top of that, each design must move a specific way underwater. For example, the 221 Flutter Spoon needed to be tweaked again and again to achieve the consistent fluttering action underwater that drives fish crazy and incites a bite. The 221 was designed with two line attachments to give the spoon two distinct actions when it is pulled up through the water. The center of mass was very strategically placed to get a slow lifelike fall on the way down. The goal was to produce an action that mimicked an injured prey fish dropping to the bottom of a water body. Robinson explained that he was adjusting these designs by ten-thousandths of an inch during this process until he got what he needed. With so much trial and error, he needed to be able to program fast and make changes even faster. “I need to get good, sound toolpaths consistently so that when I see it on the screen, I can say, ‘Yes, I trust that path’ and go with it,” Robinson said. To accomplish this, he uses Mastercam.

“I’ve worked at quite a few big manufacturers in the past. Some used Mastercam and some used other CAD/CAM systems. There’s no question which is best, but we did start with another software package because it was supported by the same Reseller as our SOLIDWORKS software, which is what we use for solid modeling. Big mistake.” This first software had an outdated interface which was unintuitive and difficult to maneuver. Robinson may have been able to power through if not for the fact that he was burning through high-performance cutters with expensive coatings because the system was changing parameters on its own. “Feeds and speeds were randomly changing, it was finding random Z depths to cut to, and wear comp was being turned on and off in the wrong places in the code. It would shut off while the cutter was engaged and gouged the part. We were struggling like mad just to get solid toolpaths laid out,” Robinson recalled. He went to the Reseller with his problems and was dismissed as not knowing how to use the program and trying to accomplish impossible tasks. At this point, Robinson had taught himself multiple CAD/CAM systems, earned multiple patents, and started his own business. Settling for “that’s impossible” was not an option.

Robinson finally decided that he couldn’t afford to be nervous about hitting the Cycle Start button on his machine and went with what he knew would work. He said, “I’m not making this up when I say that we got more done with Mastercam in the first three weeks than we did with that other software in nine months.” Without any extensive formal training, Robinson can still get the software to do “some pretty wild and powerful things.” The intuitiveness of the interface makes learning easy while still allowing advanced programming, and it pairs seamlessly with SOLIDWORKS. Instead of spending his time worrying about potential crashes or tool breakage, Robinson can focus on innovating. He can quickly and easily add operations to modify a part, copy existing toolpaths to other features without reprogramming, and utilize the power of the CAD program to make Mastercam even more effective. With Mastercam running inside of SOLIDWORKS, he can insert an external part into an already programmed part and use the same toolpaths to machine different sized cavities and features.

His newfound confidence has allowed him to explore functions like Dynamic Motion technology, which allows operators to push their feed times past what was possible before. Dynamic tools like OptiRough reduce cycle times by up to 75 percent by adjusting tool motion in real-time to maintain consistent chip load. This optimizes energy dispersal so that the chips carry almost all of the heat from machining, leaving the tool and part cool, and thereby safer. “I had some hesitation with using it alongside my smaller endmills, the twenty- or fifteen-thousand sizes. It bumped that feed up an awful lot, but that radial chip feature gave me that trust I need when I run my machine. I’ve never broken a small cutter with OptiRough,” said Robinson. He can run his machines faster than ever without fear of breaking his expensive cutters or gouging his molds.

Now Robinson buys one piece of tool steel for each part with the expectation of success. It gives him the freedom to focus on creativity. “The accuracy of today’s machinery and CAM code allows us to machine tooling with absolute precision for these very intricate products. It is always our goal to be ahead of the competition, and having these tools in place allows us to forge new paths in our industry,” he said.

Proxmire and his programmers can call Axsys whenever they have questions or need help troubleshooting or optimizing their machining process. “Whenever we have a problem, Mike Stevens is our go-to. I’ve got his personal cell phone number. I can always get ahold of him and he always gets me the information I need right away. He’s local too, so if we have a problem he can’t fix over the phone, he is here right away to take care of it,” he said. Axsys offers continued training for users of the software in their area, and they frequently reach out to companies like Schupan to go over the software’s ever-expanding features.

One such feature is the software’s extensive Tool Manager. Users can import tool libraries from respected tool manufacturers like Sandvik Coromant, optimize the paths for each tool, and then extrapolate the information. “The ability to create one cutter path and transfer it to multiple locations is huge. I use that for programming one part and then transforming it down the line for 10 different parts. This software is very good with that as far as approaches and clearance planes and fine tuning the cutter path to make it as fast as it can be. We have old tool libraries and tool holder libraries for all of our shrink fit and CAT 40 tool holders. It makes it a lot easier for simulation.”

When Proxmire simulates his parts, he uses the Verify and Backplot functions within the software. Many CAD/CAM software suites require expensive additional simulation software, but Proxmire is confident in his setup. Verify and Backplot both display onscreen any and all portions of the machining process, which users have the ability to record if they need to. Because collisions and errors are detected before the parent material ever touches the machine, operators can work through projects much faster and with greater confidence.

After simulating each part to check for any problems, Proxmire’s focus is once again on reducing cycle times. Dynamic Motion technology is a sophisticated program within the software that continuously monitors the material during machining and changes tool motion in response. This accommodation for material movement means that operators can run machines at their highest rates without endangering their material or cutting tools. “The tool lasts quite a while longer now, especially when we’re machining harder materials like tool steel. We found that Dynamic Milling gives us better tool life and definitely higher metal removal rates,” said Proxmire. He estimates that when machining steel, cycle times are now up to three times shorter from just Dynamic alone.

Customer Quote

“I’m not making this up when I say that we got more done with Mastercam in the first three weeks than we did with that other software in nine months.”

– Cory Robinson, Owner and Founder of Venom Outdoors