Precision Training Helps Midwest Manufacturers Strengthen Workforce

The Technology & Manufacturing Association (TMA) in Schaumburg, Illinois, represents more than 1,000 manufacturers and 30,000 manufacturing employees. TMA serves Midwest manufacturers looking to improve operations and strengthen their workforce. Its education programs offer manufacturing skills instruction and are customized around member needs and employee schedules.

Quick Facts

- Product Used: Mill, Lathe, Swiss, Dynamic Motion, Educational Suite

- Industry: Education

Project Details

- The Challenge: Introduce CAD/CAM instruction into manufacturer technology training program to help member companies strengthen workforce and build pipeline for in-demand skilled trades.

- The Solution: Mastercam

- Benefits:

- Exposure to robust 3D toolpaths with Dynamic Motion strategies that increase tool life, decrease cycle times, and speed up the programming process.

- Students from member companies build confidence with CNC programming and bring the experience back to their workplaces.

- Hands-on CNC instruction prepares high school students for 21st century careers and builds a pipeline for manufacturers facing worsening skills gap.

- Mastercam Reseller working with instructor to provide curriculum support and advanced training opportunities.

More than 175 students are currently enrolled in TMA’s CNC education programs. Students typically follow one of two instructor-led paths: three-level Hands-On Training or Related Theory, which is also known as the three-year apprenticeship program. Hands-On Training begins with a 16-week introduction for setting up, operating, and programming a CNC mill and CNC lathe.

The second level builds on the first and involves advanced G-code techniques. Students select proper tooling, write, run, and verify G-code programs and inspect to print specifications. Second level students also complete a capstone project.

Their first two years feature blueprint reading, shop math, and machine theory. Third-year students learn more complex methods of CNC programming and machining using Mastercam as their CAD/CAM software.

TMA’s shop is outfitted for students already in the workforce, which differentiates it from other training facilities, according to one-time TMA student Jack Krikorian, now the association’s Director of Curriculum and Instruction.

“Because we’re serving member companies, we can’t have just one type of controller, for example,” explained Krikorian. “We can’t train someone on a Haas in the evening and then the next morning have them go back to work on a FANUC controller. So, we train students on the machines they’re actually using at their companies.”

TMA has four mills – two Haas mills, one Doosan with a FANUC control and one Mazak 5-axis mill with Mazatrol. They also have a 2-axis Haas ST-10 lathe and a Doosan lathe with C&Y axes and live tooling, along with a Swiss CNC machine.

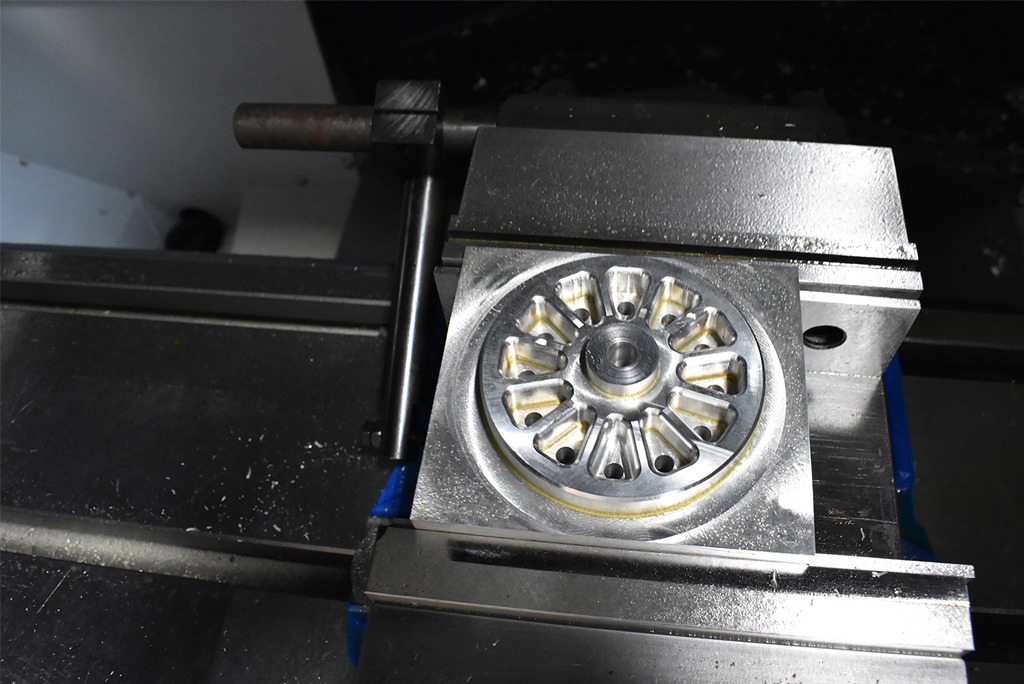

“We’re cutting metal. We cut aluminum and stainless,” said Krikorian. “We aim to be as realistic as possible to match what students are doing back at their companies.”

TMA’s computer lab has 21 simulators and Mastercam is used for CAD/CAM instruction. While not every student works for a company that uses Mastercam, said Krikorian, the training helps them learn the concepts and builds their confidence.

“One of my fears for students is that if their boss asks if they’d like to learn CAM software, they’ll be afraid,” Krikorian said. “But if they’ve gone through my class, it will motivate them to take what they’ve learned and run with it.”

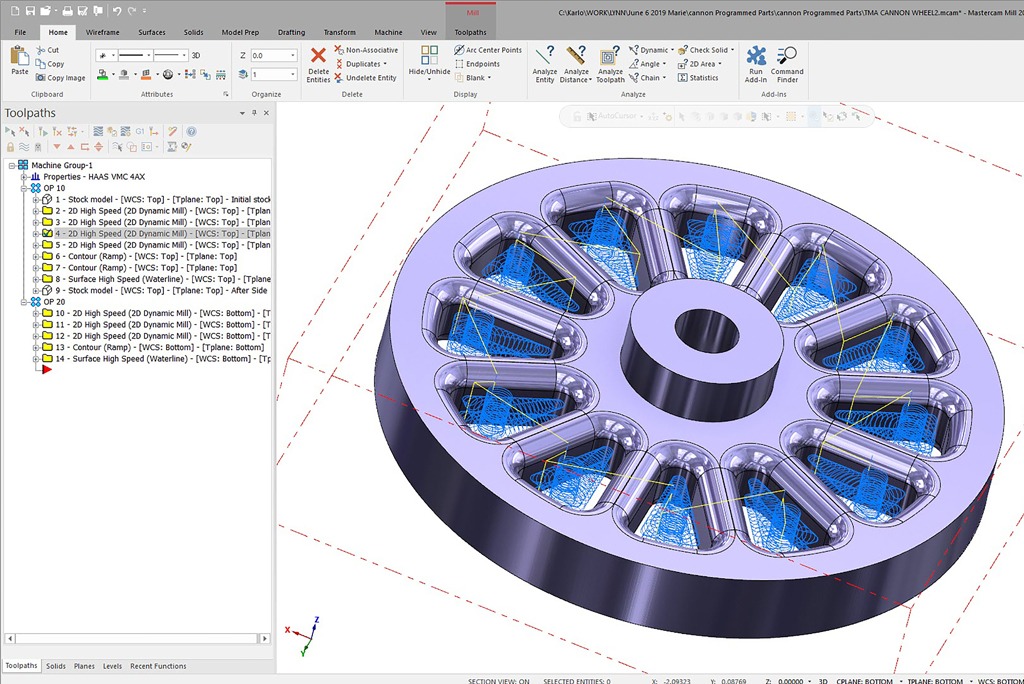

Students are exposed to 3D toolpaths that use Dynamic Motion technology. Dynamic Motion, or Dynamic Milling, uses proprietary algorithms programmed into the software to keep the tool constantly engaged with the material, allowing it to cut intricate geometries at higher speeds. The results include increased tool life, decreased cycle times, and a speedier programming process.

Krikorian often looks to Mastercam Reseller, ShopWare, Inc. to take over the students’ training. ShopWare offers classroom training, onsite training, and self-paced training in the software. Together, TMA and ShopWare set students up for success.

“I get students through the Mastercam basics so they understand and see what’s available. They learn about the different tool paths, when to use them, and which ones are going to work with the machines,” said Krikorian. “ShopWare can take them from me and help bring them to the next level.”

TMA’s Education Foundation also encourages manufacturing technology instruction by facilitating CNC training for high schools that don’t have the funds or space for machines or a program. Students can earn National Institute for Metalworking Skills (NIMS) credentials and operator credentials. The program also helps meet the demand within TMA membership for qualified CNC machinists.

“Our goal is ultimately to put students right into companies. We’re trying to be a little bit of a pipeline for our member companies,” said Krikorian, who chairs the NIMS Advisory Council. “We had one company that offered internships to some senior students. After graduation, they were offered positions, and some are still working there.”

When he’s not teaching, Krikorian is working on new curriculum to keep pace with an evolving industry.

“I want TMA be at the forefront,” said Krikorian. “That’s why we always use the latest version of Mastercam software because of all the new toolpaths and innovations coming forward with CAM.”

Krikorian’s goal is to integrate 3D printing into the TMA curriculum and to introduce more stand-alone Mastercam classes and higher level Mastercam training.

“Without a partnership with ShopWare, there’s no way we could do what we’re doing,” said Krikorian, who built his curriculum based on what he learned from the Reseller. “That’s what I love about teaching—you don’t just teach—you learn a lot of things, too.”

Customer Quote

“Computer-aided manufacturing is where everything’s going. I don’t want to be left behind. I want TMA to be at the forefront. That’s why we always use the latest version of Mastercam software because of the latest toolpaths and new innovations that are coming forward with CAM.”

– Jack Krikorian, Director of Curriculum and Advancement, Technology & Manufacturing Association, Schaumberg, Illinois

Reseller Quote

“Without a partnership with ShopWare, there’s no way we would be able to do what we’re doing. They’ve helped so much. I actually trained there, too. I watched what they did and with their help, I built my own curriculum off what I learned and from the feedback I receive from the students.”

– Jack Krikorian, Director of Curriculum and Advancement, Technology & Manufacturing Association, Schaumberg, Illinois