Bicycle Manufacturer Relies on CAD/CAM Software to Roll Prototypes to Production

Specialized Bicycle Components, Inc., designs and manufactures high-end road, mountain, and general-purpose bikes for a worldwide customer base. Founded in 1974, the California-based company designed and manufactured the first production mountain bike in 1981.

Quick Facts:

Product Used: Mastercam, Dynamic Motion, Lathe Mill, Multiaxis

Industry: Consumer Goods, Transportation

Project Details:

- The Challenge: To design and rapidly produce testable bicycle prototypes within tight design cycles.

- The Solution: Mastercam Solids, Dynamic Motion, Mill, Multiaxis, Lathe

- Benefits:

- Mastercam Solids lets programmers mix and match wireframe, solid, and surface modeling techniques.

- The Verify feature prevents tool collisions and lets programmers check for gouges, view finished part shapes, and visualize fixtures in the simulation screen.

- Dynamic Motion technology yields increased cutting efficiencies, extended tool life, and constant chip loading.

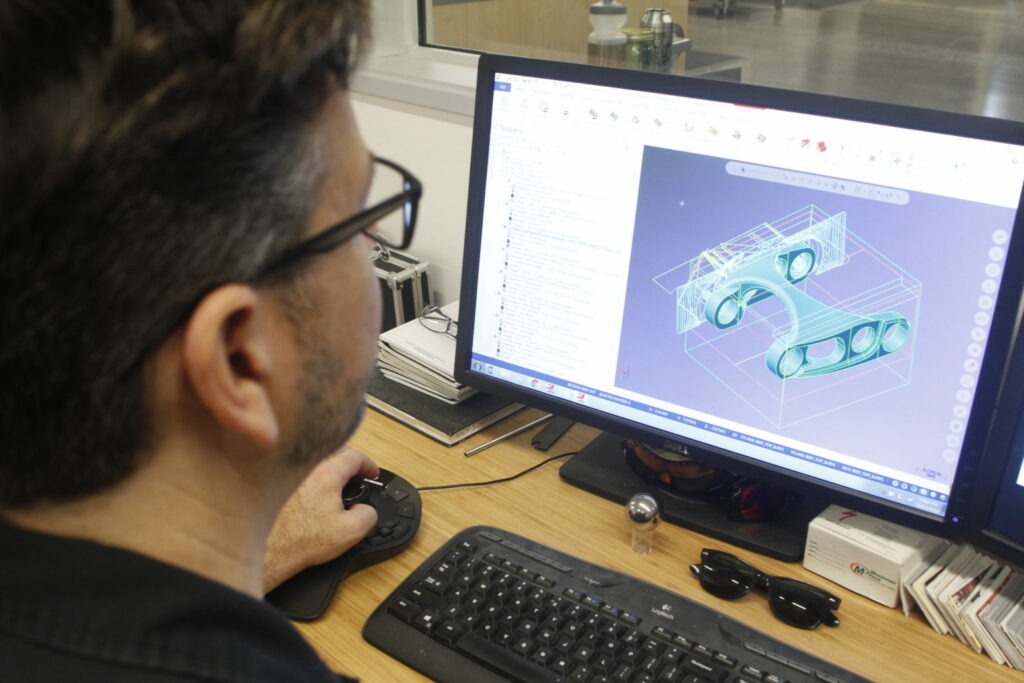

Daniel Lister is the Research & Development shop manager at the Morgan Hill, CA, facility. Here, he and his team spearhead R&D and prototyping. Projects range from molds for the carbon fiber to high-end road and mountain bike components such as suspensions, hubs, and motors. The department works with the Design Engineering team to rapidly produce testable prototypes within tight design cycles. To bring innovation to production more quickly, the team relies on Mastercam.

“We do all prototyping for literally any bike that comes through our design division,” said Lister. “It could be a new road bike that would be potentially ridden by one of our racers in the Tour de France or it could be a mountain bike for one of the riders in the World Cup downhill circuit.”

A team of seven employees makes full, rideable prototypes from materials such as aluminum, steel, titanium, and exotic alloys. Tooling for carbon fiber molds is made in-house and the shop produces molds for wheels in its Roval Wheel line, frame molds for road and mountain bikes, and sections of carbon fiber frames.

One part that challenged the prototyping team was a thin-walled bicycle shell component. Using Mastercam Solids, Lister created a series of solid model fixtures for the first stage of machining. Next, the part was sunk into a mating fixture and backfilled with wax. Lister created 3- and 4-axis toolpaths to perform complex internal surfacing and build fixturing while the part was suspended in wax. The final piece had a wall thickness of 0.040 inches, the bounding box size was 3.5 cubic inches.

“I was able to build the wax fixturing and fully assemble it, see what was going to happen by using the Verify feature, and have it come together seamlessly to get the finalized parts,” he said.

Verify allows programmers to check for gouges, view finished shapes of parts, and visualize fixtures in a simulation screen. Productivity increases and problems are addressed before parts are ever cut.

“If we don’t use Verify, we usually get ourselves into trouble,” said Lister. “We use it on every single part that comes through.”

During new carbon-fiber mold production, high speed Dynamic Motion toolpaths from previous molds serve as templates for roughing mold cavities.

“We rough the cavities, do our semi-finishing and full-finishing cycles with the ball and bull end mills, and then dial in all of our insert and slider locations.”

Machining these pieces is tricky because inserts and sliders must be matched perfectly with surface features on mold halves. With 4-axis machining, tapered surface finishes are created, and post processing operations are minimized. Lister adds that, since adopting Dynamic milling, the company has benefitted from increased cutting efficiencies, extended tool life, and constant chip loading.

CAD/CAM software helps bolster team collaboration. They can create templates that may be referenced when new parts arrive and programmers can scrub toolpaths, craft new geometries, and view previous part setups.

“The versatility and speed at which we can execute these prototypes is why we enjoy using the software,” said Lister.

When programmers encounter the occasional machining hiccup, they contact their local Mastercam Reseller, Sierra CAD/CAM, Inc. in Browns Valley, CA, for advice. “It can be complex or just a bug or tweak that needs to be made and Jack (Tiffany) or Dan (McGourty) will say, ‘It looks like you missed this and this—here is a better way to do it,’” said Lister. “Or they’ll say, “Wait, that could be a bug. I’ll send this one off.’”

New hires are sent to Sierra’s headquarters for training. Lister hopes to get the entire team out to Browns Valley for more training soon.

Customer Quote

“We’re using Mastercam to fully prototype just about any part that comes through in a regular design cycle. So, we can work on projects that are coming out for production in the next three months or in the next three to five years.”

– Daniel Lister, Research & Development Shop Manager

Reseller Quote

“It can be complex or just a bug or tweak that needs to be made and Jack (Tiffany) or Dan (McGourty) will say, ‘It looks like you missed this and this—here is a better way to do it.”

Daniel Lister, Research & Development Shop Manager