San Diego Machine Tech Program Leads the Way to Jobs, Puts San Diego City College on the Map

The Machine Technology Program at San Diego City College is known for its strong curriculum that prepares its students for life on the shop floor. Students take a series of 11 classes leading to an Associates of Science Degree in Machine Technology, and several certificates of achievement – including Performance, CNC Technology, Computer Aided Manufacturing, CNC Operator, Computer Numerical Control Technology, and Machine Technology – unless they are already machinists who are there for training in the latest technology.

Quick Fact

- Product Used: Education Suite, Demo/HLE

- Industry: Education

Project Details

- The Challenge: The Machine Technology Program (MACT) at San Diego City College has been teaching manufacturing technology since the early 1900s. Throughout the years instructors have had to keep up with changing technology in order to ensure that their students graduate with the skills and practical experience to work in the real world. In the 21st century, the challenge is no different.

- The Solution: Educational Suite, Demo/HLE, Dynamic Motion

- Benefits:

- Instructors can teach students both legacy toolpaths and Dynamic toolpaths so that they are prepared for any type of programming scenario

- Dynamic Milling technology offers students the ability to learn more efficient cutting techniques to save manufacturing time and costs.

- The Mastercam Demo/Home Learning Edition allows students to work on projects at home, update them at school and finish their assignments in less time.

- The software is being used at most manufacturing facilities in Southern California, so students are proficient in the industry-standard CAD/CAM software whether they are new to the technology or veterans.

Jack Bollinger, Professor of Machine Technology in the Engineering Department of San Diego City College, brings practical experience to his students, having worked in machine shops since the early 1980s. He and his team have created a curriculum that is considered a national model for machining education by the U.S. Department of Education and the National Science Foundation, both of which asked him to develop a sensible curriculum that could be disseminated across North America in a way everyone could understand. Bollinger sent his ideas regarding the CAD/CAM and CNC machining portions to them for distribution to roughly 600 different companies to critique. “It allowed us to get a rounded idea of what these companies wanted,” said Bollinger.

Bollinger welcomes the input from the college’s advisory board companies, some of which are helmed by his former students. His six adjunct instructors and four teaching assistants also work in industry and keep him apprised as to whether they need to focus more on one particular skill or even if a technique is becoming antiquated.

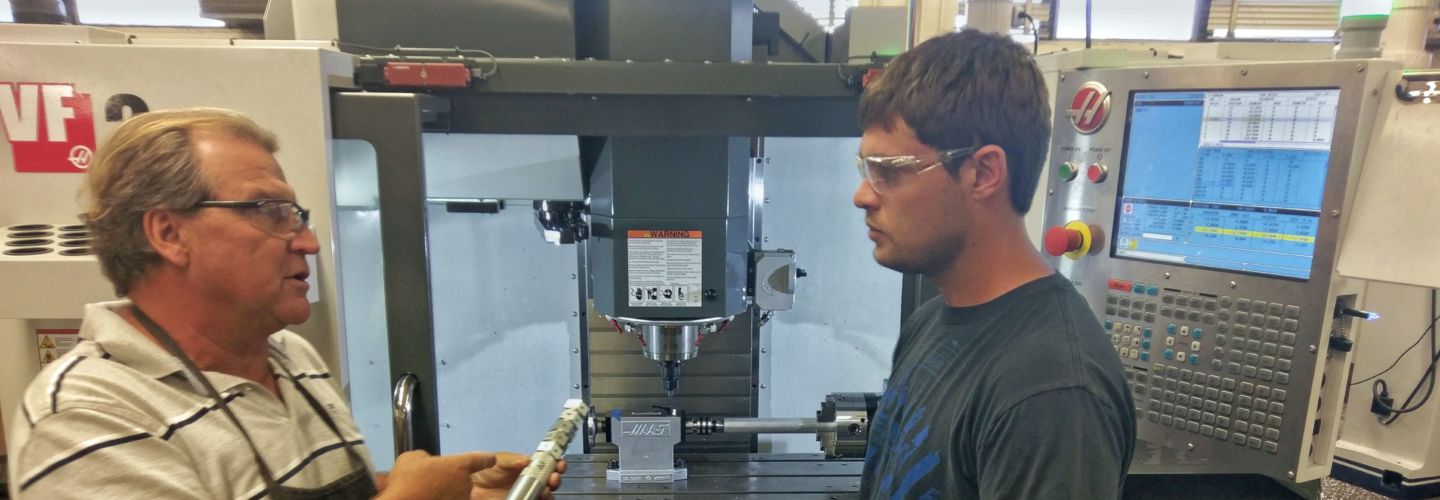

City College has almost 9,000 square feet of shop space with seven CNC milling machines, several manual machines, and three 3D printers as well as two computer labs. Students don’t move into the computer lab until the first two courses are completed. The Basic Principles/Machine Tech class uses the manual machines to teach the principles of milling operations while Intro to CNC and EDM, teaches students how to set up and operate CNC machine tools.

The Intro to CAD/CAM class takes the students into the computer lab and introduces them to CAD/CAM programming using 80 seats of Mastercam® software. “The students are basically using Mastercam to generate code,” said Bollinger, “but the curriculum also gets into contours, pockets, hole drilling, tapping and reaming, along with all the associated working files that go with those operations.” The introductory class teaches the types of CAD/CAM work students will find in actual job shops. Students then attend lab classes with extended lab hours which include videos for each of the projects, all of which are found on Bollinger’s web page. “Following this,” said Bollinger, “we go deeper into machining. Their first project or two utilizes hand coding and we teach them to use macros and loops and how to integrate their CAD/CAM programs into a project. And then we introduce them to 4-axis programming, as well as Mastercam’s Dynamic Milling to achieve faster, more efficient metal cutting operations. By teaching them both regular tool paths and Dynamic tool paths, we’re making them more marketable when they leave us. As they proceed, the work is progressively harder, and they receive less help from the staff in order to make them more self-reliant.”

Students also learn how to make adjustments. Instructors teach how to calculate feeds and speeds by giving students the parameters, but they don’t tell them which speeds and feeds to use. “We teach them how to do it and give them examples, but they have to figure it out,” said Bollinger. Students are provided the Mastercam Demo/Home Learning Edition. They can work on their projects at home, update them at school, and then finish their projects.

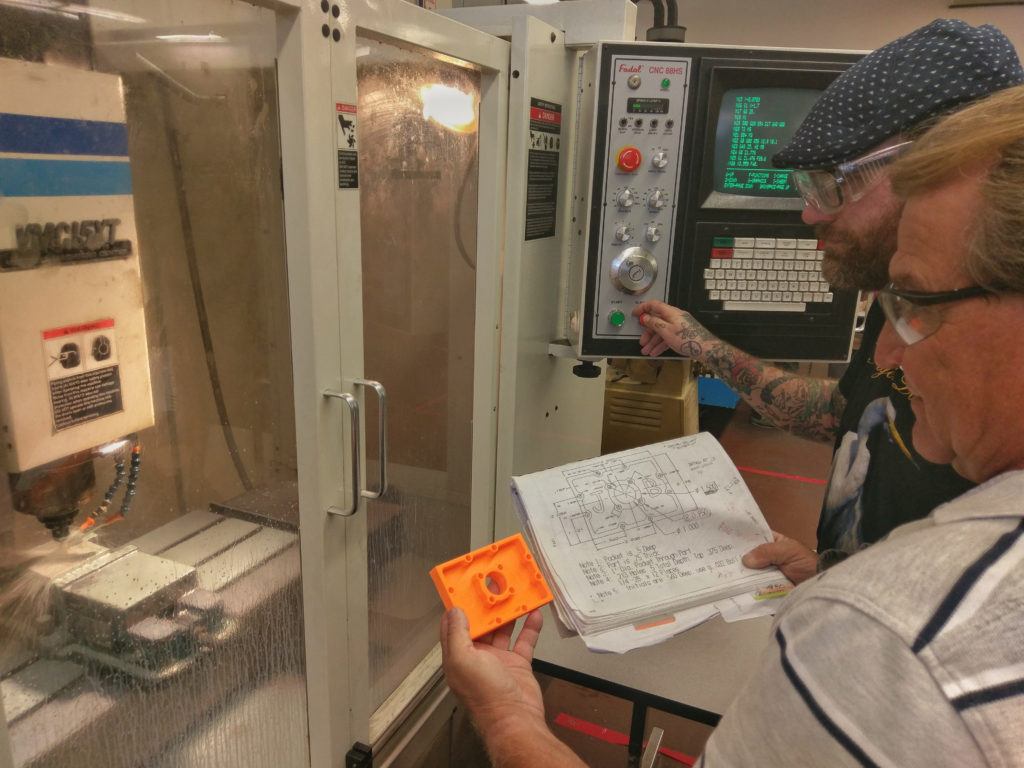

The Advanced Mastercam course teaches the toolpaths for surfaces and solid modeling. They are also taught 3D printing by selecting their toolpaths and cutting the part in Mastercam as a solid model. Using a verification process, the program is saved as an .STL file and loaded into one of the 3D printers. This rapid prototyping operation lets the students see, in plastic, what the part will look like when machined out of metal on one of the CNC mills.

The instructors design projects that feature drilled holes and reamed holes, and taps and pockets and contours, and just about everything else that can be programmed in Mastercam and machined on a CNC mill. “We stay with Mastercam because that’s what industry is using. When our students learn how to make the projects in our curriculum, they will be able to perform the same operations on anyone’s real-world project,” said Bollinger.

Note: The MACT program is supported by the Center for Applied Competitive Technologies (CACT), a program that falls under the California Community College Chancellor’s Office Economic and Workforce Development (EWD) Program. The CACT at San Diego City College more specifically provides technology education, manufacturing training, and consulting services through workshops, courses, and funding to support efforts to keep the program innovative and competitive.