Community College Manufacturing Program Offsets Statewide Skills Deficit

Getting young people excited about manufacturing could make the skills gap a thing of the past. Through education, possible biases toward industrial trades can be eliminated. Demonstrating the power and possibilities of CNC machines and CAD/CAM software is an important factor in debunking manufacturing misconceptions and replenishing the nation’s skilled labor pool.

Quick Facts

- Product Used: Mastercam Educational Suite, Dynamic Motion

- Industry: Education

Project Details

- The Challenge: Find a user-friendly, powerful CAD/CAM software package that will keep students interested and prepare them for manufacturing careers.

- The Solution: Mastercam, the most widely used CNC software for CAD/CAM operations.

- Benefits:

- Dynamic Motion technology uses the full flute length for more consistent tool wear and extended tool life.

- Mastercam’s variety of toolpaths include 3D HST Hybrid toolpaths that maintain Z-level cuts in steep areas and fill in shallow areas with scallop motion.

- Easy to teach—students grasp the technology and enjoy watching the chips fly.

Rowan-Cabarrus Community College in Salisbury, North Carolina, was established in 1963 in response to community and economic development needs. Initially an industrial education center, it evolved into an institution with multiple programs and campuses. Today, Rowan-Cabarrus Community College—along with fellow North Carolina colleges and universities—is playing a crucial role in addressing a statewide skilled labor shortage.

According to Raleigh-based myFutureNC Commission, a commission focused on educational attainment, 50 percent of North Carolina employers are unable to hire needed workers due to lack of employable skills, technical skills, and overall education.

Despite the state’s explosive growth in size and economic activity, its pool of qualified laborers remains stagnant. The commission reported that, by 2020, 67 percent of North Carolina jobs will require a post-secondary degree or quality credentials. Currently, only 49 percent of North Carolinians between the ages of 25 and 44 meet these requirements. To close the educational attainment gap, myFutureNC set a goal to ensure that two million North Carolinians, ages 25 to 44, receive high-quality, post-secondary degrees or credentials by 2030.

Rowan-Cabarrus Community College is doing its part to address the labor crisis by serving 25,000 students at seven locations throughout North Carolina’s Rowan and Cabarrus counties.

Jason Hill, instructor of Computer Integrated Machining for Rowan-Cabarrus, brings years of industry experience to the classroom to help prepare students for careers in manufacturing. His hands-on manufacturing experience allows him to help students sharpen skills sought by future employers.

“It was eye-opening to see what companies need,” he said of his time in production facilities. “Everybody was looking for well-rounded machinists rather than people that can just run machines. Employees need to know the design side and the engineering side.”

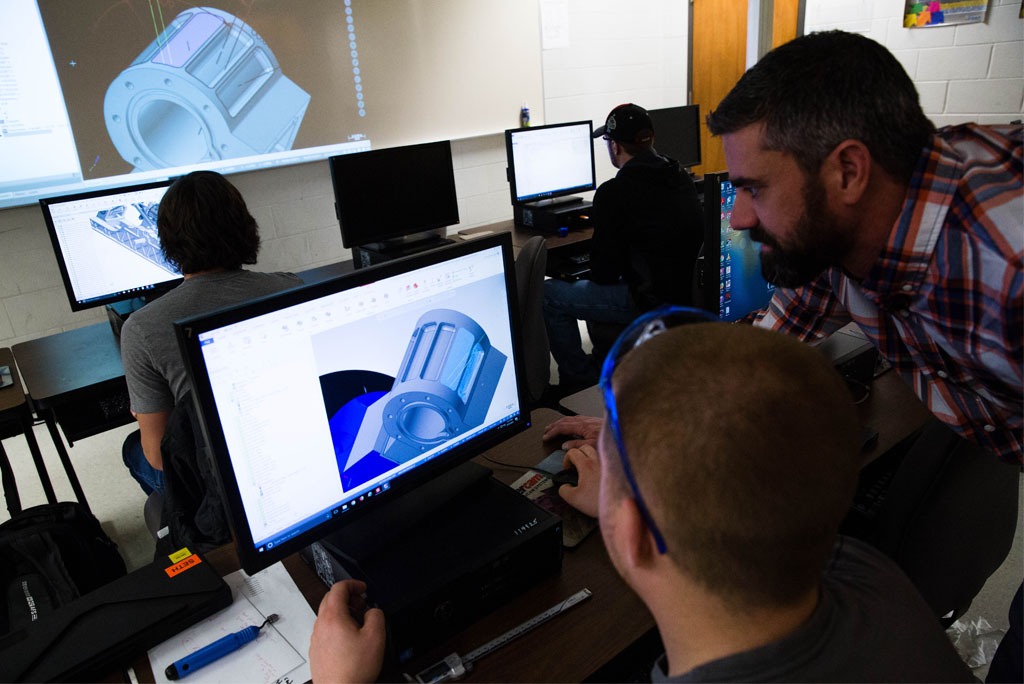

With a keen eye on design for manufacturing, Hill spearheads a curriculum that encompasses CNC and CAM technology. His classes include Intro to CAM, CAM 1 & 2, Advanced Multiaxis Applications, and CNC Machining. To tie this curriculum together and equip students with powerful CAD/CAM software, Rowan-Cabarrus uses Mastercam.

Hill emphasizes design for manufacturing, especially in his capstone class in which students design and manufacture engines. “We usually do steam engines because they’re fun, they run, and they aren’t finicky,” he said.

To produce the engines, Hill’s class redesigns existing ones in SOLIDWORKS® and program toolpaths in Mastercam. Students are excited about the software capabilities and many continue their education beyond the classroom. For these eager pupils, putting in an effort both in and out of the classroom is paying off.

“In my classes, anybody that wants to work has a full-time job before they graduate,” said Hill. “All of my current students have full time jobs. I have always pushed CAM and CNC technology. The students who embrace it do great.”

Rowan-Cabarrus students in the Computer Integrated Machining Technology program enjoy hands-on projects, a proven way to build interest in machining. In the Intro to CAM class, for example, students produce their own license plates.

“The requirement is removing material,” Hill said. “I push that throughout all the classes because that’s the whole goal of machining: to remove material to make the part.”

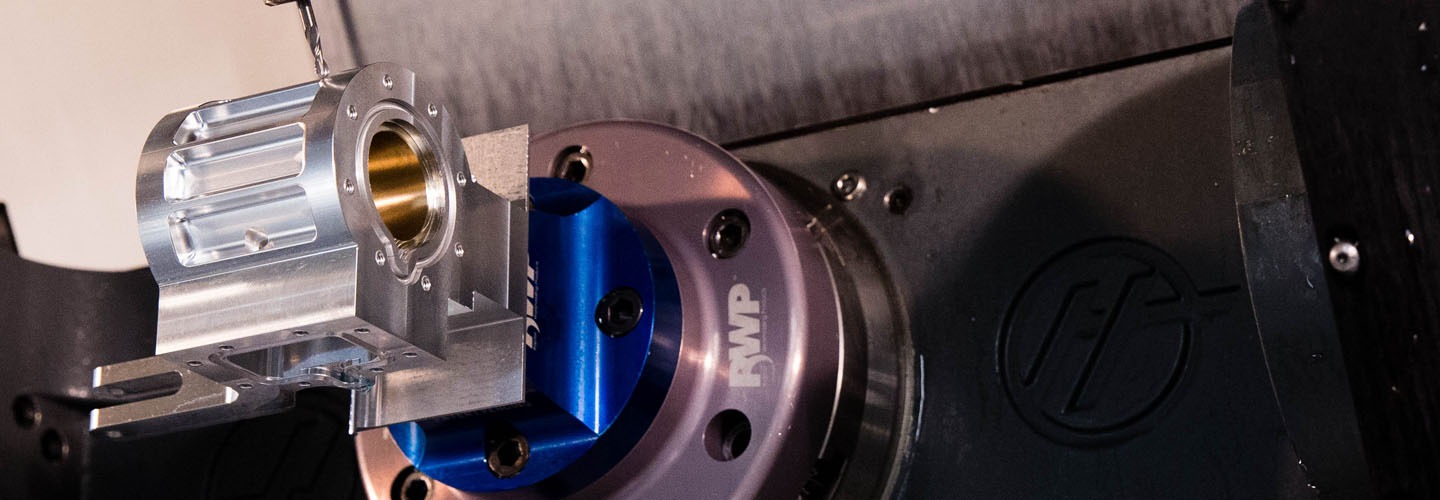

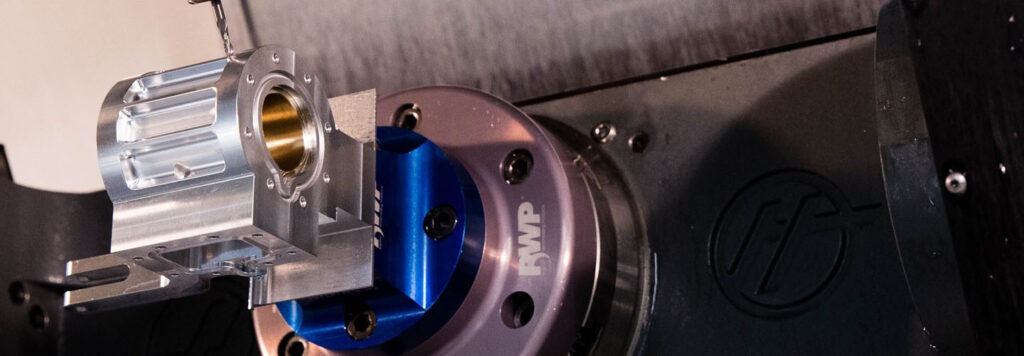

Mastercam’s Dynamic Motion technology is a prime focus in Hill’s class. Compared to a traditional cutting toolpath that uses only the nose of the tool, Dynamic Motion uses the full flute length for more consistent tool wear and extended tool life.

“We do studies using traditional methods of stepping down, and then we’ll do the same part using Dynamic Motion technology, burying the tool an inch-and-a-half in and letting it cut,” said Hill.

According to Hill, Dynamic Motion is easy to teach; students grasp the technology and always appreciate seeing chips fly.

“Everybody loves watching Dynamic Motion because it throws chips everywhere,” he said. “It’s exciting, especially to people who’ve never seen it before. I’ll let the cutting tool go as fast as it can. We’ll go back and forth and talk about feed rates or chip per tooth and surface footage. Students understand how to use the whole tool to rough the part out—it’s not just material removal.”

Mastercam provides an added layer of confidence when machining a new part, Hill added. If the part is made of the same material as the previous one, the machinist can apply what he already learned without starting over.

“I already know it’s going to work,” said Hill. “We’re not guessing anymore. For example, I know I can run 400 inches per minute at 12,000 RPM at 1.5 inches deep with a 1/2-inch end mill and it will be fine. The part shape doesn’t matter. That saves time in proofing every part out. We can throw it on the machine and rough it out.”

One aspect of Mastercam that the class appreciates is the variety of available toolpaths, specifically 3D HST Hybrid toolpaths that maintain Z-level cuts in steep areas and fill in shallow areas with scallop motion. Combining Waterline (constant Z) and Scallop motion at the same Z level means the entire part is cut.

“The new hybrid toolpath blended from Waterline and Scallop is awesome,” said Hill. “That’s my first go-to now.”

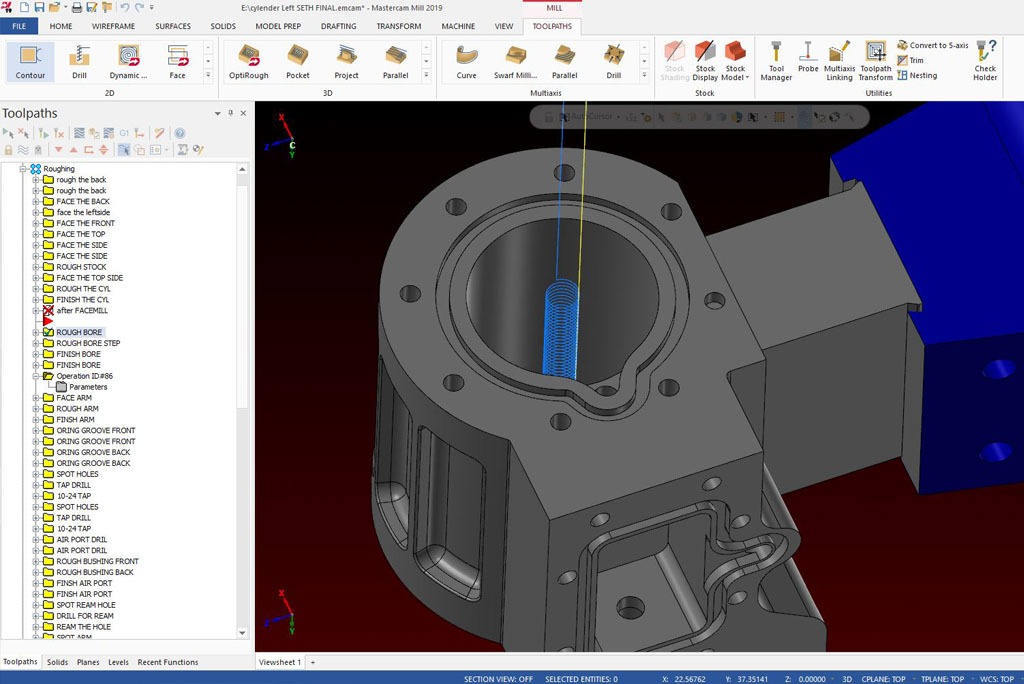

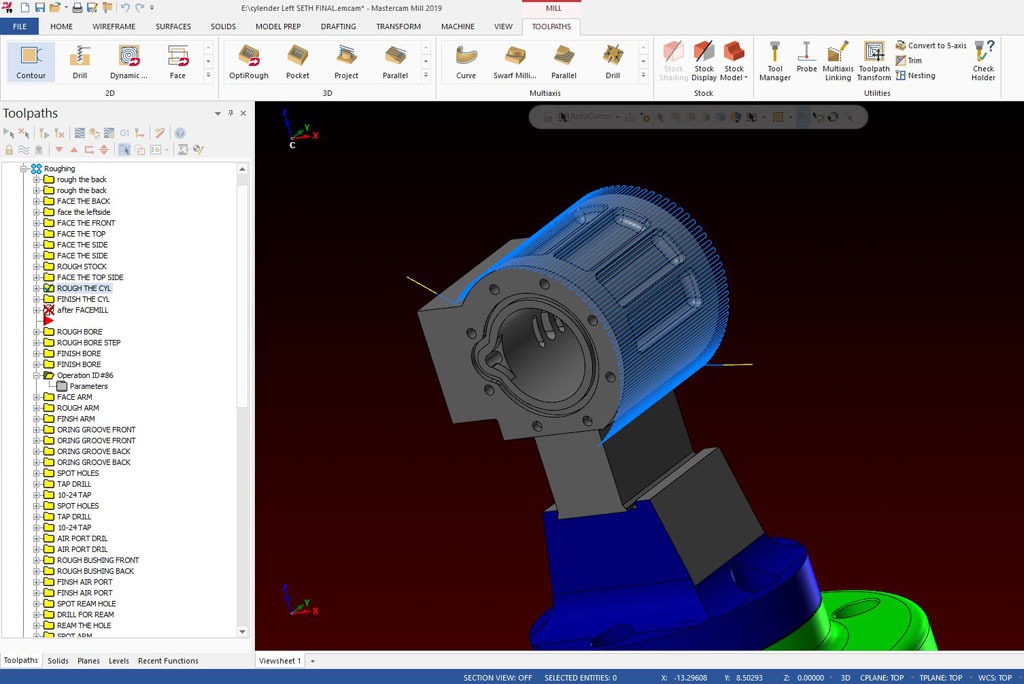

Currently, Hill’s students are producing engine cylinders. A 5-axis part that was designed in Mastercam, each cylinder measures 21” x 8” x 3”—the biggest part that the students could fit on the machine. The design is based on a part recovered from the wreck of the USS Monitor, a Civil War-era steam-propelled ironclad ship that sank off the coast of North Carolina. Hill relies on the expertise of Jimmy Wakeford and his staff at Barefoot CNC to lend expertise if needed.

“You can buy different software packages, but you won’t get the Mastercam family—there’s always somebody to help you,” said Hill.

As North Carolina educational institutions and businesses band together to combat the statewide skilled-labor shortage, Rowan-Cabarrus Community College Computer Integrated Machining Technology program instructors will do their part to prepare students for successful manufacturing careers.

Customer Quote

“In my classes, anybody that wants to work has a full-time job before they graduate. All of my current students have fulltime jobs. I have always pushed CAM and CNC technology. The students who embrace it do great.”

—Jason Hill, Instructor of Computer Integrated Machining, Rowan-Cabarrus Community College, Salisbury, North Carolina

Reseller Quote

“You can buy different software packages, but you won’t get the Mastercam family—there’s always somebody to help you.”

—Jason Hill, Instructor of Computer Integrated Machining, Rowan-Cabarrus Community College, Salisbury, North Carolina