CNC-Siponen Oy Uses Mastercam to Create Functional, Beautiful Piece

Reseller Zenex Computing Oy tasked customer CNC-Siponen Oy to machine a table with a 3D model of their local area on its top. Although something like this had never been done before by either company, Mastercam CAD/CAM software made the process easy.

Quick Facts

- Product Used: Mill, Router

- Industry: Custom Woodworking

Project Details:

- The Challenge: Machining a one-of-a-kind conference table out of frangible wood.

- The Solution: Mastercam, the most widely used CNC software for machining applications

- Benefits:

- OptiRough toolpaths that remove even the most difficult material quickly and safely.

- Finishing toolpaths like Raster that can achieve tight tolerances and superb surface finishes.

- Easy to understand, intuitive interface.

- Network of Resellers that provide their customers with exceptional support.

Certified Mastercam Reseller Zenex Computing Oy, based in Klaukkala, Finland, not only provides exceptional technical support to its clients, it also gives them opportunities to show off their machining skills.

Recently, Zenex hired customer CNC-Siponen Oy to create a one-of-a-kind conference table. Siponen is a manufacturing company based outside of Helsinki. It started as a one-man carpentry shop but has grown to be much more.

Production Manager, Tapio Tanskanen, started with Siponen in 2006 and has been a firsthand witness to this growth. He shared that much of Siponen’s success is a result of its standing as one of only a handful of Finnish CNC manufacturers in the wood industry. “We machine wooden and plastic components for various industry needs, and our focus is machining sub-construction and design. Typical applications are interior mock-up models, company logos, wall panels for exhibitions, and carpentry components for high quality furniture,” he said. Zenex’s table, while being within their normal range of work, required all the skill and creativity Siponen had to offer.

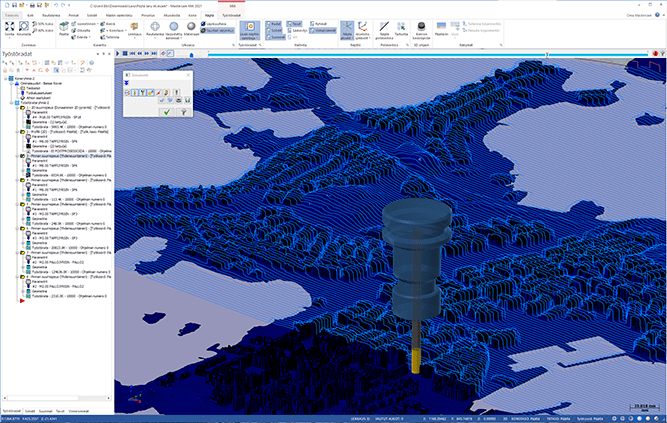

The table features a model of Lauttasaari, a district outside of Helsinki. Designing the table took a great deal of research and ingenuity. “There isn’t much useful 3D data from Google Earth, so we had to use data from a Finnish land survey office and laser scanning from airplanes to model that highland,” said Eki Tossavainen, Chief Technology Officer at Zenex.

The team at Zenex combined the data into a CAD model within Mastercam, relying on the Verisurf add-on for additional support in scale modeling. Tossavainen continued, “We saved it all as a Mastercam file and sent that to our customer Siponen, because they use and love the software, too.”

The table was designed to be made out of ash hardwood, not only because of the natural beauty of the wood, but for its hardiness as well. Ash is one of the best woods for machining, as it withstands the stress of the operations with little cracking or peeling.

However, Tanskanen explained that anyone working with wood on a router needs to understand how the material behaves and how the grain direction dictates how to move the tooling. If the bit is spinning clockwise, the router path has to move counterclockwise.

All wood, ash included, is predisposed to having what carpenters refer to as character, or flaws in the grain, whether that be irregular grain pathways or even knots. Each one of these irregularities requires special attention, or the fluting runs the risk of blowing out the wood, peeling back wood fibers haphazardly, and leaving messy lines.

Once Siponen had a safe program laid out for the wood, cutting began. The table was machined in two operations – the underside pockets for the legs, and then the top cityscape – and took almost 20 hours to mill, even with automatic tool changes.

The milling time would have been unbearably longer without OptiRough, a bi-directional cutting technique that moves large amounts of material quickly and safely.

Part of the software’s Dynamic Motion technology, OptiRough takes large, aggressive cuts while maintaining consistent tool-material contact to avoid gouges and tool damage. “OptiRough was great to remove a lot of material before using smaller endmills. It’s faster than other toolpaths, and that was important because of how long the milling time already was. It reduced our roughing time by maybe 50 percent on this project,” said Tanskanen.

“There’s no point in milling for longer when OptiRough finds that optimal toolpath and cuts faster. I use OptiRough every time when it’s possible. That toolpath is the best way to rough a material away, especially when you need to cut out a lot of material.”

After roughing, following cuts were made by bi-directional raster toolpaths. Because of the wood’s frangibility due to its grain, Siponen chose to use finish raster toolpaths to complete the project.

Raster was the best choice to avoid cracking and peeling. “The tool is moving in the same direction as the grain of the wood. The model has such small details that I had to avoid cracking the wood as best I could,” explained Tanskanen.

Then the team finished the table by sanding it down and covering the milled city with glass. They delivered the table to Zenex and were pleased to see how much the Zenex team appreciated their work. Tossavainen marveled, “It’s so easy to start conversations while seated around this table, because no one’s ever seen this kind of table before.”

Customer Quote

“That’s why we use Mastercam. You can choose any other program you like, but those won’t have options for special applications. In Mastercam, you can get everything you want and still do those special ‘extra’ things. No other software can handle this kind of work.”

—Tapio Tanskanen, Production Manager, CNC-Siponen Oy, Finland