Catawba Valley Community College (CVCC) in Hickory, North Carolina, relies on Mastercam to train the local workforce, close the skills gap, and help improve the area economy.

Quick Facts:

Product Used: Mastercam Mill, Mastercam for SOLIDWORKS, Dynamic Motion, Educational Suite, Multiaxis

Industry: Education

Project Details

- The Challenge: Find a powerful, easy-to-use CAD/CAM software that prepares technical school students for the needs of future employers.

- The Solution: Mastercam manufacturing solutions including Mastercam Mill, Dynamic Motion technology, and Mastercam for SOLIDWORKS®.

- Benefits:

- Flexibility and network of support

- Industry leading CAD/CAM with most installed seats

- Ease of use for the novice machinist

- Depth of features for manufacturing professionals

After the economic recessions of the 1990s and 2000s, and the subsequent relocation of several furniture and textile businesses, Catawba County, North Carolina, is reinventing itself as a manufacturing hub.

Training the local workforce is a crucial first step in rebuilding the area economy. An institution at the center of this county-wide effort is Catawba Valley Community College in Hickory, North Carolina.

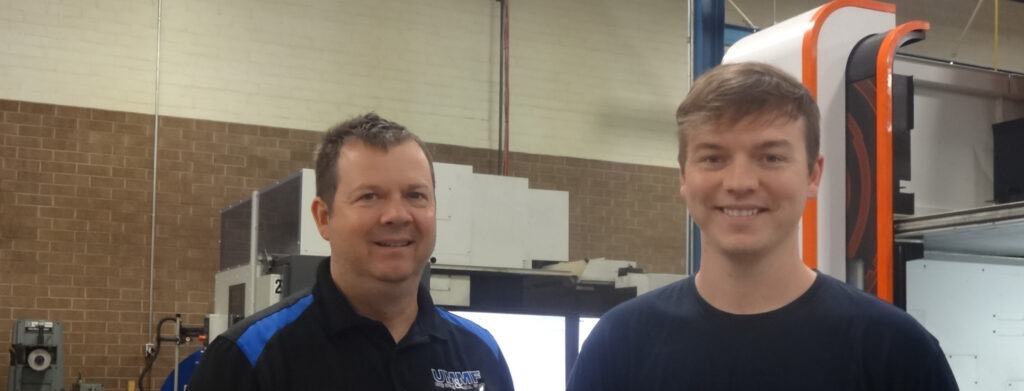

CVCC revamped its CNC machining program to meet the needs of the local manufacturing sector. According to Steven Rhoads, Director of the CVCC Computer-Integrated Machining Technology program, the skills gap in Catawba and surrounding counties is a critical issue for business owners. Because manufacturers struggle to fill machinist positions, the college expanded its continuing education program to include more course offerings.

“Companies are having to hire folks off the street to run CNC machines,” said Rhoads. “When manufacturers contact us, we sit down with them and write up a syllabus that includes what they want students to learn in those 10 weeks. We pack in as much as we can, and the companies love it. We are doing this to address the skills gap.”

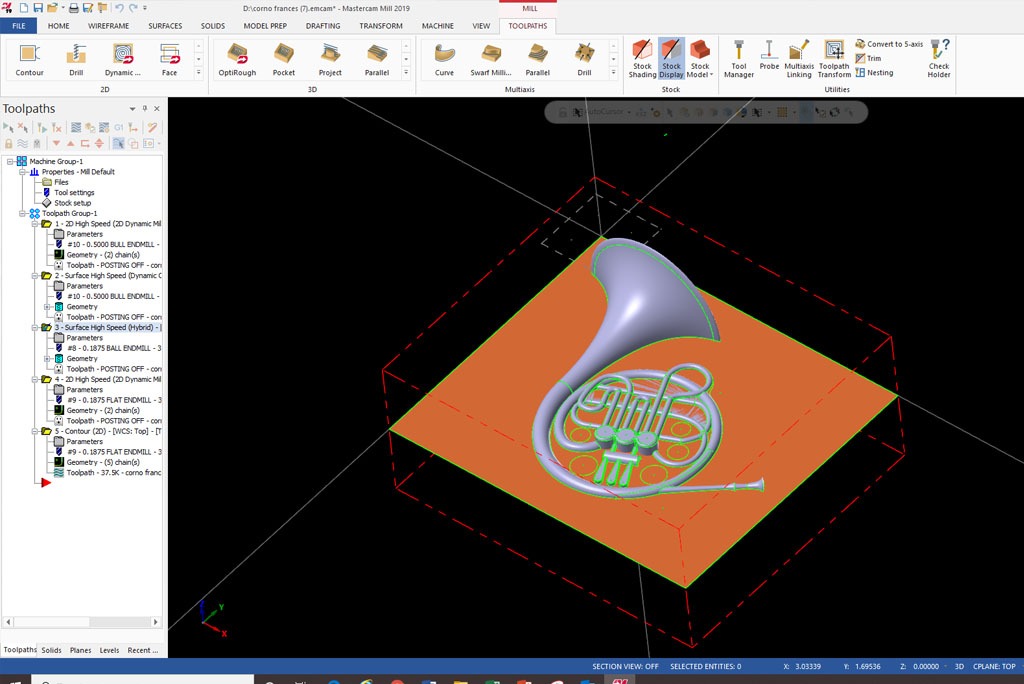

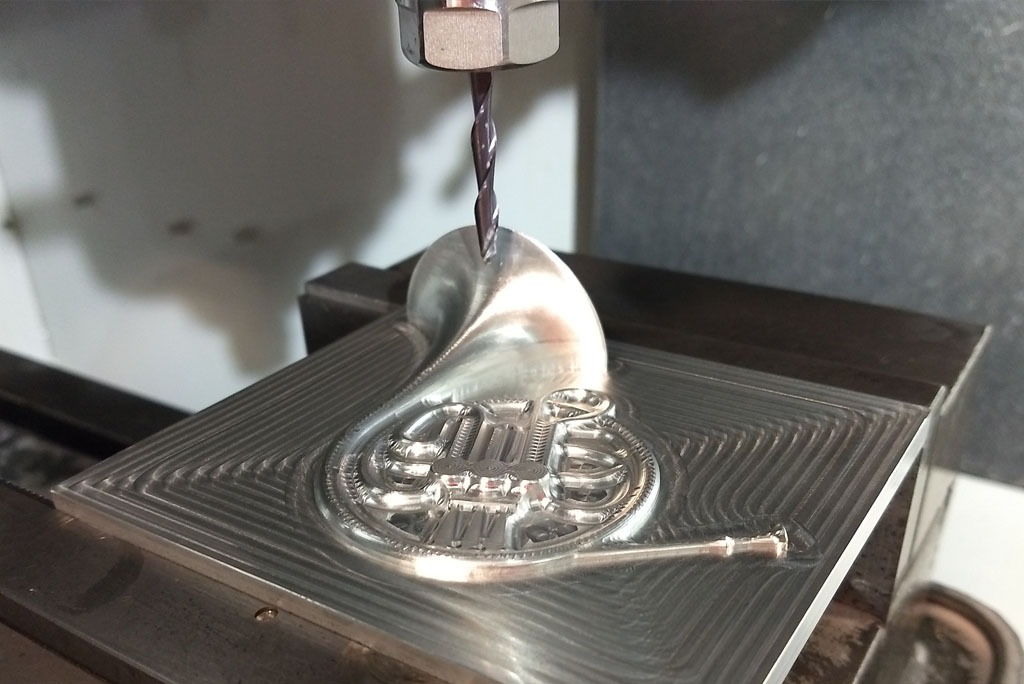

The curriculum prepares students with the skills to take an idea from concept through design, development, and production to finished product. Coursework includes manual machining, engineering design, computer-aided design (CAD), computer-aided machining (CAM), advanced computerized numeric control (CNC) equipment, high-speed multiaxis machining, and more.

After speaking with area businesses about the college’s Machining Integrated Technology curriculum, CVCC instructors investigated CAD/CAM software options to support their equipment investment and best prepare students for machining careers. They soon learned that most local manufacturers use Mastercam. The software’s flexibility and network of support make it the most widely used CAD/CAM software in industry and education. Mastercam continues to prove itself as a great fit for CVCC’s manufacturing program.

In addition to machining certification, CVCC graduates can earn one-year diplomas and associate degrees. An intensive eight-week Mastercam summer class focuses on the use and benefits of the CAD/CAM software. More advanced classes cover Mastercam for SOLIDWORKS®, which integrates CAD and CAM so programmers can standardize their CAD file database without compromising NC programming quality. To date, CVCC’s hands-on learning approach is a proven method for student success.

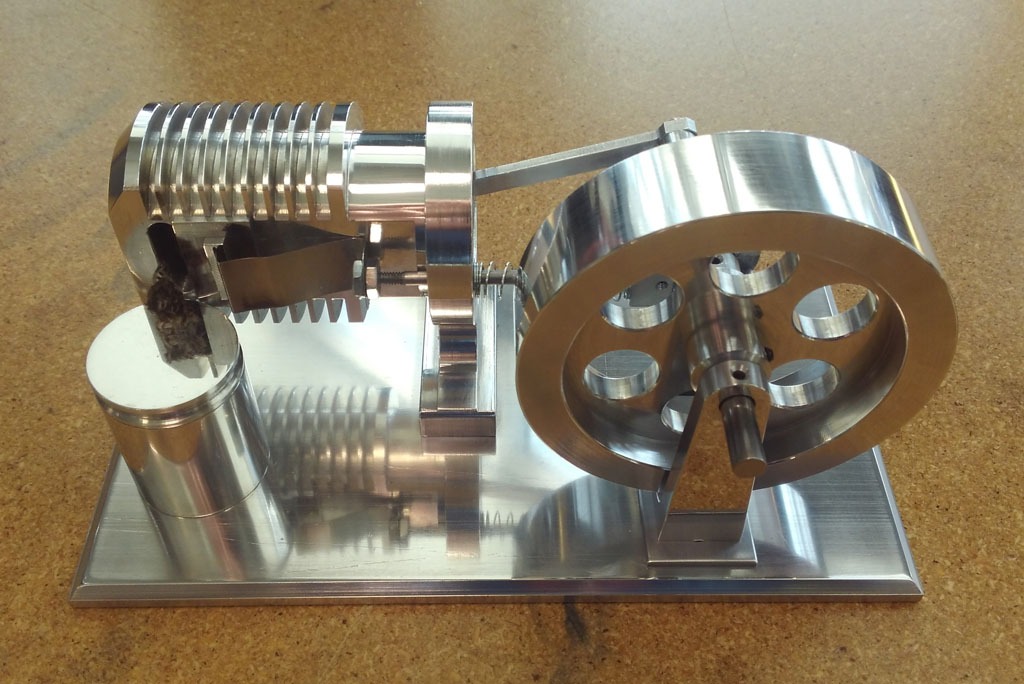

Before they begin machining, students study Mastercam Dynamic Motion technology. To better understand how Dynamic Motion works, students design and manufacture Stirling engines comprised of 20 component parts. In 2019, one Catawba Valley student’s Fire-eater engine took second place in the Phillips Machinist Cutting Edge Parts Competition: Student Edition. Such projects let budding machinists express creativity while they learn programming and machining techniques.

“I’ve used several different CAD/CAM programs and Mastercam is the easiest to me,” said Rhoads. “Dynamic Milling changed the way that we machine.”

In addition to speed and ease of use, the software’s flexibility and extensive choice of toolpaths are key features, especially for the novice machinist.

“I’m plugged in with Mastercam,” said Matt Logan, CVCC Integrated Machining Technology student. “I enjoy it. Everyone has their own way of doing things. I’ve seen students machine the same part I did, but in a totally different way and get the same result.”

CAD/CAM knowledge and shop floor experience are credentials that manufacturers are looking for, even in entry level employees. Though overall expertise is not expected, machining and programming skills are. Employers seek new hires who can set up machines, touch the tools off, and run parts, added Rhoads.

To combat North Carolina’s skills gap, a focus on industry needs is central to the CVCC machining program. The college offers Apprenticeship Catawba, a partnership with local manufacturers and school districts, to offer apprenticeships to high school students. Tuition and books free and an apprentice earns paychecks while earning Journeyman certification or an Associate degree in Applied Science, Computer Integrated Machining Technology.

CVCC and its apprenticeship partners appeal to high school students by offering affordable career options. Promoting the trades to potential apprentices is receiving a positive response. Local manufacturers recruit high school students and hold signing days similar to those held for athletes who commit to playing college sports.

“Upon graduation, a former student can go out and get a really good job,” said Rhoads. “The company invests in him and, hopefully, the student will stay with that company for a long time.”

Customer Quote

“I’ve used several different CAM programs and, to me, Mastercam is the easiest. Students can see tool wear and feed, too. Dynamic Milling changed the way that they machine.”

—Steven Rhoads, Director of Computer-Integrated Machining Technology, Catawba Valley Community College, Hickory, North Carolina