High School Promotes Hands-on Introduction to CNC and Machining Careers

Computer Aided Design and Engineering Technologies (CADET) is one of 26 College Tech Prep Initiatives available to students at Kent Theodore Roosevelt High School in Kent, Ohio, under Ohio’s Six-District Educational Compact. The Compact engages nearly 25,000 students in rigorous, project-based courses designed to prepare them for college and careers.

Quick Facts

- Product Used: Mastercam Design

- Industry: Education, Aerospace

Project Details:

- The Challenge: Successfully integrate CAD/CAM instruction into college tech prep initiative that introduces students to design and engineering technologies and prepares them for college and careers.

- The Solution: Mastercam Educational Suite

- The Benefits:

- Delivers CAD, milling, turning, router, and wire EDM programming in a single package.

- User-friendly interface gets students cutting parts quickly.

- Hands-on CNC instruction provides students with real-world work experience and opportunities.

- Mastercam Representative support team partners with school to provide problem-solving assistance.

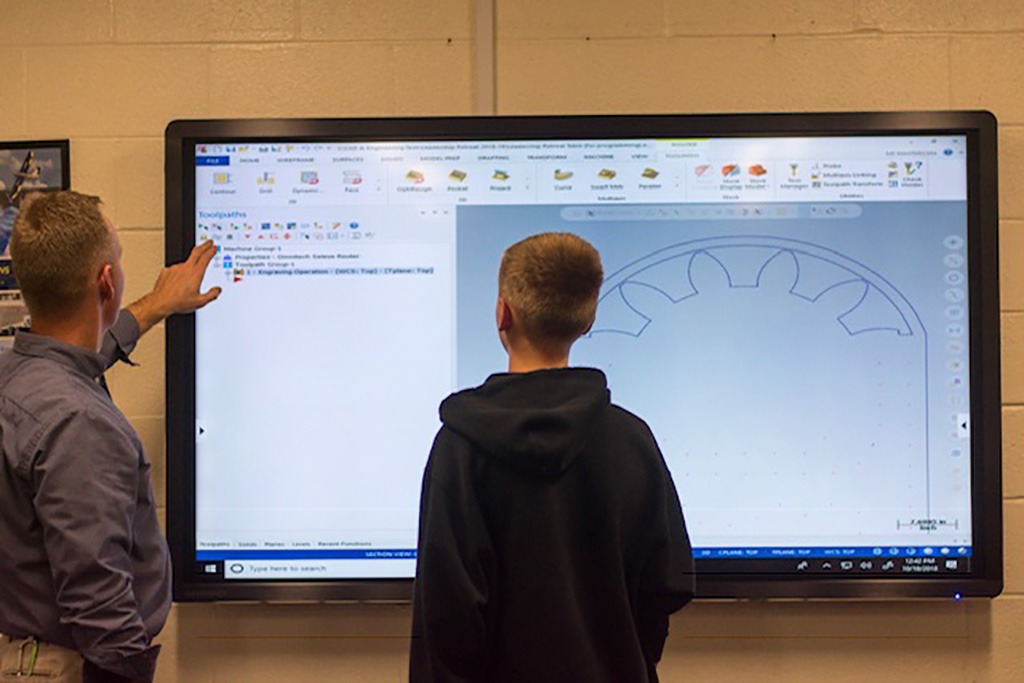

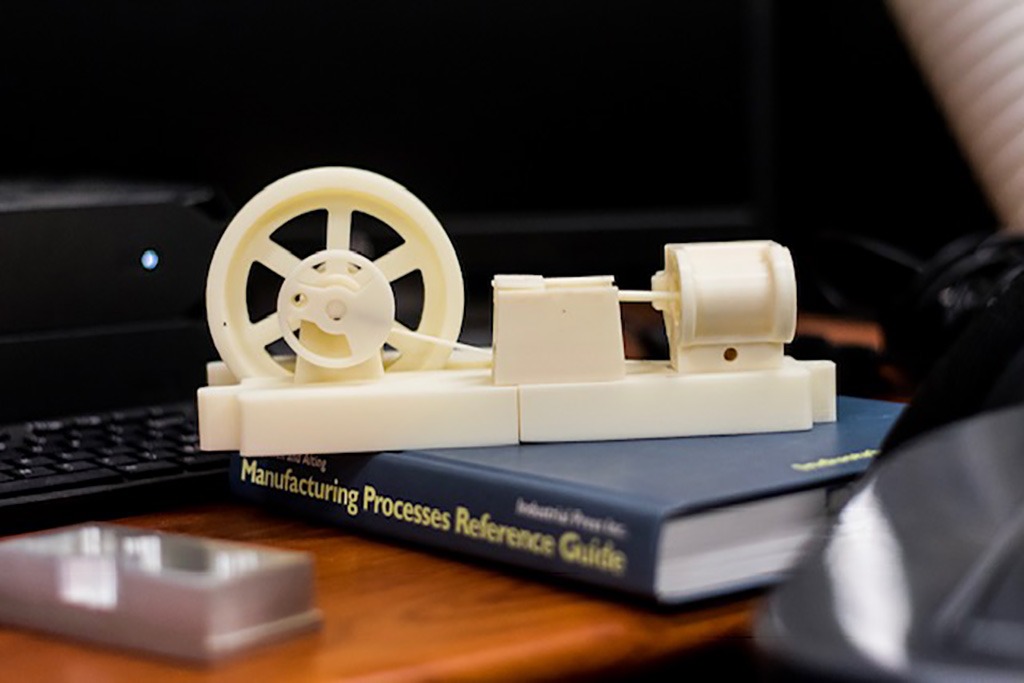

CADET students take four courses during their last two years of high school: Engineering Design, Manufacturing Operations, Machine Tools, and CNC Programming for Industrial Mills and Lathes. Students learn to design, basic machining, and G-code during their junior year (Level 1) and more about CNC programming, the manufacturing process, and project management as seniors (Level 2). They are expected to design and make their own projects, and they have an opportunity to go out and work.

CADET instructors Troy Shear and Jeff Bee stress the importance of the basics, familiarizing students with all the tools in the lab including the manual ones. According to Shear, this foundational knowledge is critical, especially when teaching students how to execute a design. For CNC programming, CADET instruction integrates Mastercam.

Spear noted, “We were initially using another CAM software with most of our lathes and machines, except for our new Haas ST10 machine, which used Mastercam Mill-Turn.” One of the reasons for switching to Mastercam, Spear shared, was the school wasn’t getting the support and the instruction they needed from the other CAM package. Kevin Richardson from Mastercam Representative FASTech Inc. stepped in to help with the transition.

Richardson demonstrated Mastercam Mill-Turn and Mastercam Lathe, including the simple dragging feature in Mastercam’s Model Prep, which allows the programmer to create and manipulate a solid model within the CAM software to add or remove holds, and adjust dimensions or diameters.

“We were both really impressed with the simplicity of the process,” Spear said. “At that point, we were all in.”

Bee appreciates the attention and support CADET gets from FASTech. “It’s great having a partner who realizes the importance of ‘teaching the teachers’ so that we’re confident when we’re questioned by the students.”

A recent class had 22 students enrolled in the CADET program. More than a quarter were female students, a percentage that continues to increase each year. At the time, Marielle Muncy and Audrey Hepler were doing their senior year, interdisciplinary Capstone projects with CADET.

“I have always been interested in how things work—from start to finish,” said Muncy who is studying CAM manufacturing. “I love making my ideas come to life—from computer to real life.” Muncy is currently considering architectural engineering or mechanical engineering programs at colleges in Ohio.

For Hepler, the CADET Program fueled her interest in design. She intended to major in industrial design at either the Cleveland Institute of Art or The University of Cincinnati.

CADET students not only design and make products; they market them—to a local vendor that provides wooden Greek letters to sororities at nearby Kent State University. Students go on to use Mastercam Lathe or Mastercam Mill, becoming familiar with different axes and machines. The students are now producing the Greek letters at a fraction of the cost of what the company was previously paying.

“Making the letters is the students’ hands-on introduction to CNC. They take a drawing—a DWG file—bring it into Mastercam, scale it, learn to put a toolpath to it, and nest it,” Spear said. “Within an hour, we can have it on the machine, material already mic’d, then nest and make the G-code. Once the students learn how to read the G-code, they can write it. So they see the whole progression.”

Both instructors take students to visit local manufacturers and Spear has introduced Mastercam software to the Stanton Middle School STEM Club to advance their understanding of manufacturing processes.

“As powerful as Mastercam is, we find it ideal for CAD/CAM education,” Spear said. “It has everything we need to help us prepare today’s students for tomorrow’s challenges.”

Customer Quote

As powerful as Mastercam is, we find it ideal for CAD/CAM education. It has everything we need to help us prepare today’s students for tomorrow’s challenges.

—Troy Spear, Instructor, CAD & Engineering Technologies, Kent Theodore Roosevelt High School, Kent, Ohio

Mastercam Representative Quote

“These guys take control of the computer, and we figure things out together on speaker phone. It’s wonderful to have somebody on the other end… It’s great having a partner who realizes the importance of ‘teaching the teachers’ so that we’re confident when we are questioned by the students.”

—Jeff Bee, Instructor, CAD & Engineering Technologies, Kent Theodore Roosevelt High School, Kent, Ohio