Butler Tech Transforms High School to Career Track

Butler Tech in Colerain Township, Ohio, trains high school students for dozens of skilled professions while they complete academic courses. Boasting a 95-percent job placement rate, the Cincinnati-area school’s precision machining program covers manual machining, CNC machining, milling, gaging, and surface grinding. Graduates go on to promising careers as CNC machinists, engineers, journeymen, and tool and die makers.

Quick Facts

- Product Used: Educational Suite, Dynamic Motion, Mill, Lathe

- Industry: Education

Project Details:

- The Challenge: Prepare future CNC programmers and machinists to meet the Cincinnati-area’s labor demand.

- The Solution: Mastercam, the most widely used CAD/CAM software in education and industry.

- Benefits:

- Mastercam Backplot and Verify utilities check tool motion.

- New CAD users gravitate to Mastercam’s ease of use and flexibility.

- Students learn Mastercam design, Dynamic toolpaths, and CNC milling, turning, and machining to prepare for first jobs as CNC programmers and machinists.

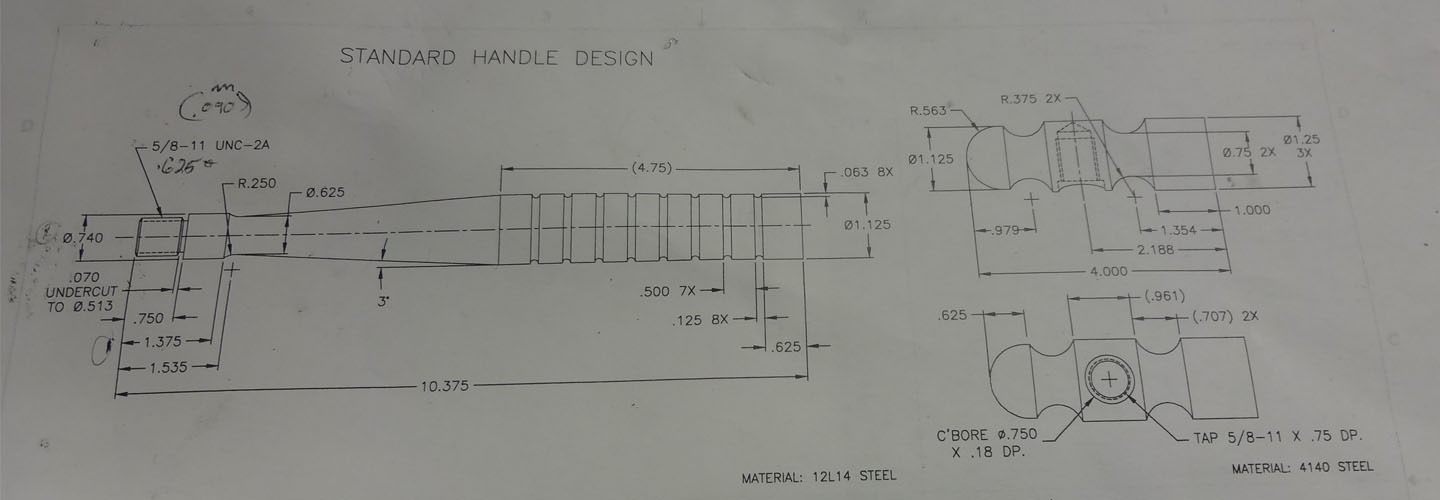

David Fox, Butler Tech instructor, heads the popular program at the Colerain High School Career Center. His students begin the machining program with the basics: micrometers, calipers, and blueprints. Next comes operating manual mills and lathes followed by advanced manufacturing skills, namely CNC programming and machining. To design parts and run their machines, Butler Tech students use Mastercam.

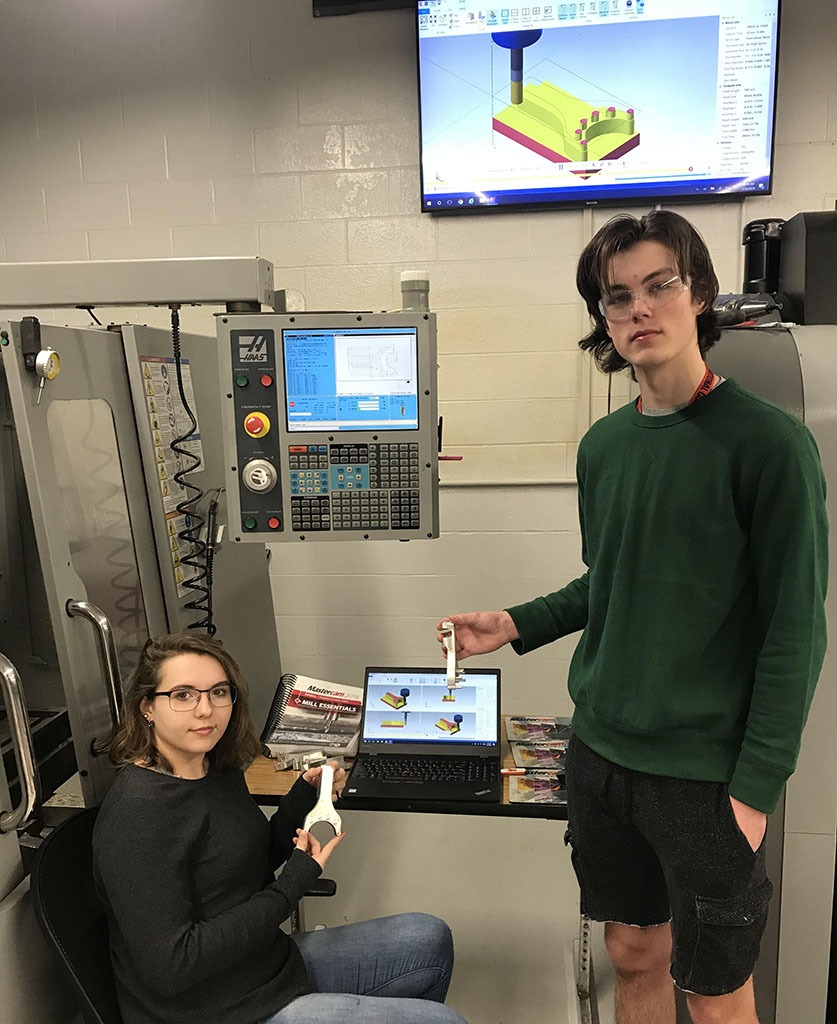

“We usually have seven or eight guys rotating between the groups, learning manual and CNC lathe, CNC mill, and CAD/CAM—all at the same time,” said Fox. “And of course, they love Mastercam because they can do so much with it.”

Thanks to government grant money and donations from area manufacturers, Butler Tech renovated its entire shop, which is a big draw for Colerain High School students. Since the renovation, Butler Tech’s enrollment of 18 students per year jumped to 42. The shop includes a CNC laboratory area equipped with CAD/CAM software, simulated programming, and manual machine areas. Grinders, mills, lathes, CNC machining centers, and simulators round out the classroom. The machine setup was donated by local manufacturers.

“Companies are excited to help out,” said Fox. “Employers were saying, ‘Let’s get some grant money for this program—we are in dire need of machinists.’”

That dire need is a direct result of the “silver tsunami” that is taking manufacturing and a slew of other American industries by storm. As the nation’s workforce reaches retirement age, companies must find ways to attract, train, and retain the next generations. Butler Tech is doing its part to fill those employment gaps by preparing students for manufacturing careers. To support its design and CNC machining curriculum, the school purchased seats of Mastercam. With 28 students doubling up to use the software, others must wait to get programming time.

“The students who are waiting get impatient for their turns,” said Fox. “I tell them to just work hard, they will get their chance…They get so excited when they see Mastercam.”

To introduce high school students to CAD/CAM, Fox keeps things simple at first. Students draw boxes then learn to set grids and ribbon bars. They study toolpaths and use Mastercam Backplot and Verify utilities to check tool motion. For an initial assignment, Butler students designed and machined key chains shaped like their school mascot. The students learned quickly, and their instructor picked up a few things along the way.

“I am fluent in Mastercam, but every semester a student will teach me something new,” said Fox. “They’re so computer literate—it’s amazing what the kids can do.”

Students learn designing, machining and how to apply manufacturing solutions to real-life situations. One group of Butler students summoned their creativity and skills to improve the life of a fellow student. The young woman, who has the use of one arm, worked in a hospital. She could not make up hospital beds because she was unable to put on her required latex gloves.

After some brainstorming, Butler students designed and manufactured a pronged part that can be carried in a pocket and snapped onto a linen cart. A latex glove is draped over the part prongs, allowing a hand to be easily inserted into the open glove. Now that latex gloves are not an obstacle for the student, she can complete her job tasks. Aptly named the Glove Aid, the Mastercam-designed product continues to draw attention.

“We’re getting calls from a lot of people, including people with cerebral palsy, that need a Glove Aid,” said Fox. “So, we’re actually remanufacturing it right now.”

In addition to gaining design and problem-solving skills, Butler Tech students learn all-around machining skills, including boring, drilling, tapping, grinding, and programming Dynamic milling toolpaths. By the time they graduate, students have mastered measurements, blueprints, math, trigonometry, RPM formulas—just about anything they may encounter in the machining world.

As a technical program instructor, Fox’s main goal is to help his students qualify for and find employment. Many local manufacturers offer Butler students apprenticeships and others offer direct employment or co-op positions.

“The high-tech jobs are what they’re after, and we do our best to position them for that,” said Fox.

The Butler Tech Precision Machining program prepares high school graduates for ongoing success in the manufacturing field, a field not limited to machinist careers. Many go on to attend universities and graduate with engineering degrees. Every year, Butler holds an open house and invites potential employers to meet with juniors and discuss employment opportunities. At a recent open house, every junior was hired.

The shortage of skilled machinists and programmers, coupled with the looming silver tsunami, fuel the push to attract young workers to the manufacturing sector.

Companies are desperate to get more people in this field, at both the high school and college levels, according to Fox. Most companies that Butler Tech works with use Mastercam, so including it in the course curriculum is a proven resume builder. Many employers that recruit from Butler expect new hires to work with the software as soon as they start their jobs.

“Some companies are having the students write Mastercam programs at their machines, so it’s becoming a big part of the process,” said Fox. “You don’t just have a dedicated programmer anymore; you have everybody writing their own programs.”

With so many new programmers and machinists working with Mastercam, Fox is grateful for the support of his reseller, FASTech Inc. The staff helps with CAD/CAM problem-solving, troubleshooting, machining strategies—virtually any obstacle that Fox and his students may encounter.

As the manufacturing sector continues to search for new, skilled employees to replace the wave of retirees, Butler Tech will keep preparing its students in CAD/CAM and machining to help fill the labor void.

Customer Quote

“I am fluent in Mastercam, but every semester, a student will teach me something new. They’re so computer literate—it’s amazing what the kids can do.”

– David Fox, Instructor, Butler Tech, Colerain Township, Ohio