Featured Stories

No Room for Error: Delivering Mission-Critical Projects with Mastercam

For Catamount Machine Works, manufacturing precision parts for the defense industry demands absolute accuracy. The stakes are high, and failure is not an option.

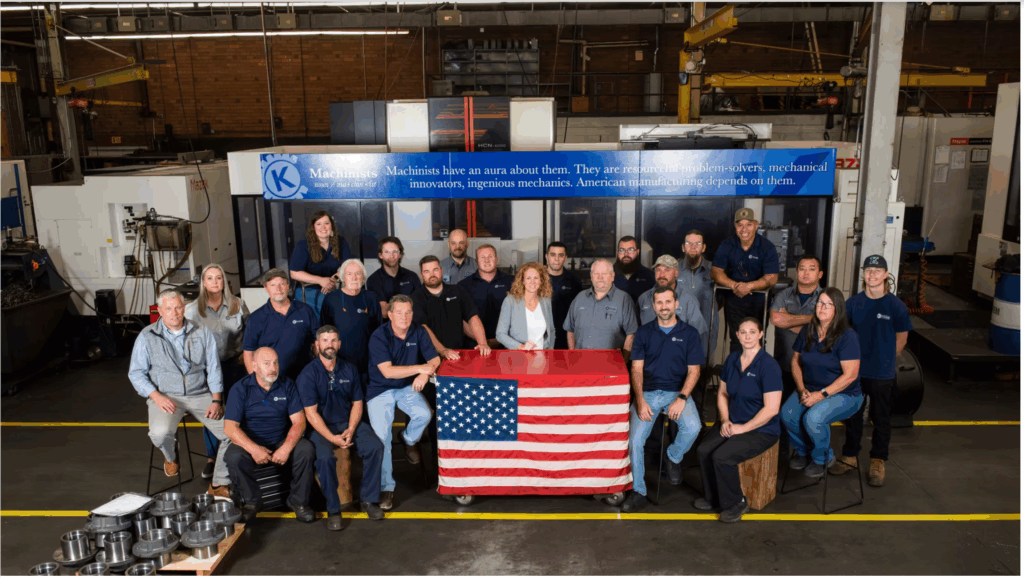

Cutting Costs and Cycle Times: How Mastercam Helped Ketchie Scale Smarter

Ketchie Inc., a precision machine shop in North Carolina, faced competitive pressure and ambitious growth goals in a saturated manufacturing market. By integrating Mastercam with its existing Mazak equipment, the company streamlined operations, embraced multi-axis machining, and optimized toolpaths. These upgrades led to reduced cycle times, lower tooling costs, and increased production capacity

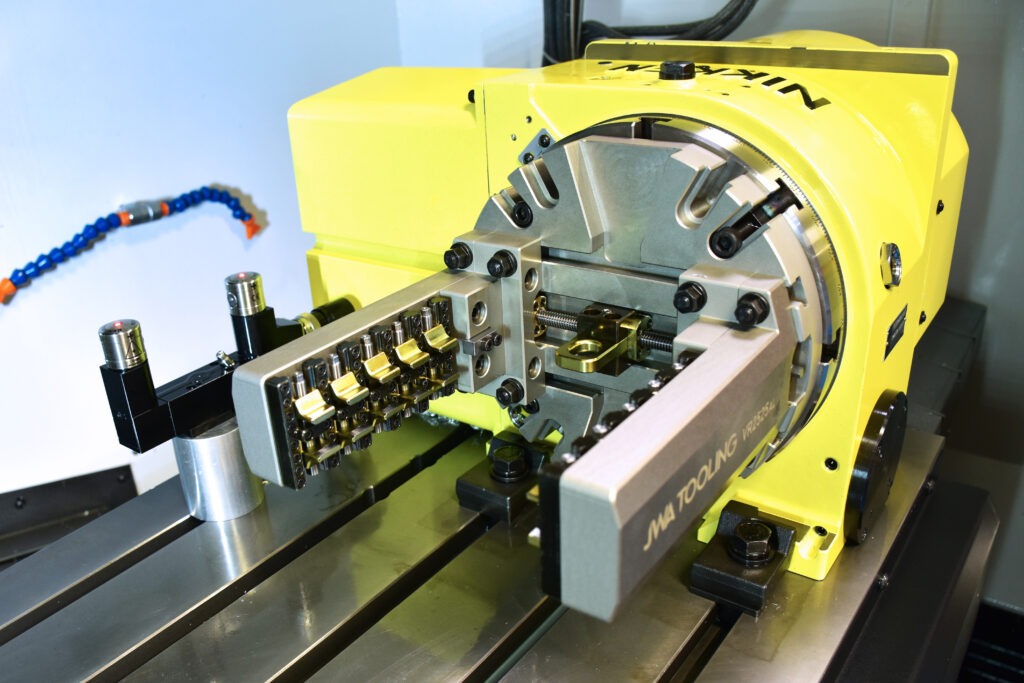

Precision at Five Microns

JWA CNC Precision, a precision manufacturing operation in the United Kingdom is proving that with the right CAM technology, even the most challenging tolerances and complex variations can be mastered consistently, efficiently, and profitably.

Mastering the Future

In a world where technical education is often overlooked, Diman Regional Vocational Technical High School is proving that machining is not just a trade—it’s a transformative career path. With Mastercam at the core of its cutting-edge curriculum, Diman is shaping the next generation of manufacturing leaders and making waves on the national stage at SkillsUSA.

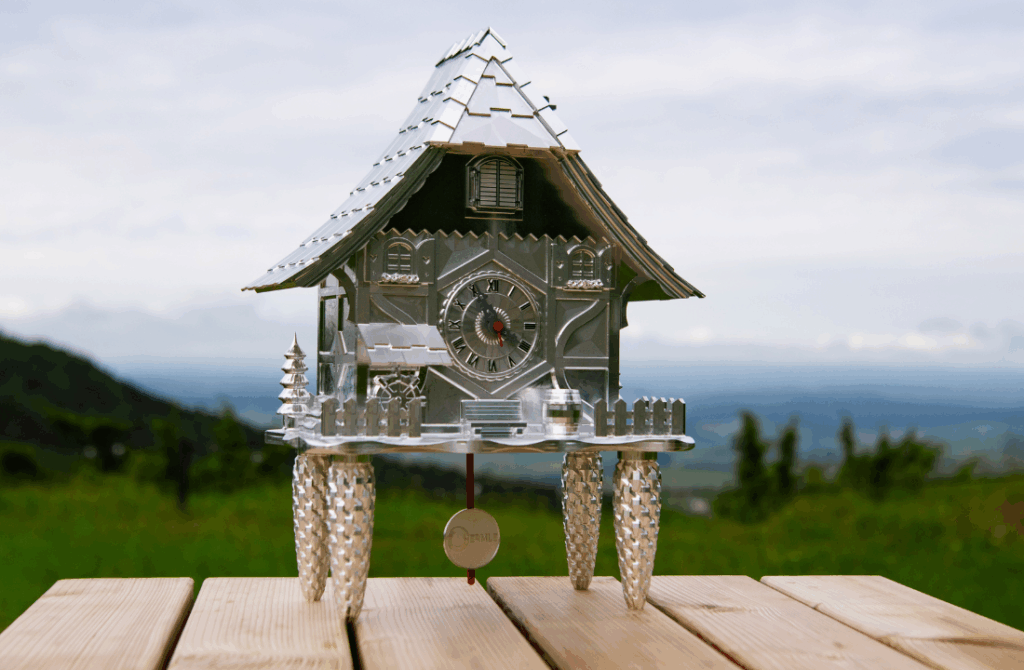

When Craftsmanship Meets Programming

A compelling example of the evolution in precision machining is this modern reinterpretation of the traditional cuckoo clock. Through the integration of advanced programming and machining techniques, our project team set out to merge old-world craftsmanship with modern-day machining precision.

Programming the Future

A hands-on precision machining program at Southwestern Illinois College (SWIC) is having a big impact on bridging the skills gap by training a new generation of digitally fluent, industry-ready programmers.

From Garage Startup to Aerospace Supplier

Innovative Technology Manufacturing uses Mastercam to run its CNC machines and produce complex parts for the aerospace and defense industries.

From Student to Instructor

Tri-County Technical College teaches Mastercam to prepare students for successful manufacturing careers.

Nicholson Manufacturing Ltd.

Nicholson Manufacturing uses Mastercam CAM and APlus AM technologies to produce debarker knives for the lumber industry.

Canada France Hawaii Telescope

At the most scientifically productive site for astronomy in the world, Greg Green has the opportunity to machine parts that hold million-dollar chips, all with a 24-year-old machine, CAD/CAM software, and creative fixturing.

Bridgerland Technical College

Bridgerland Technical College uses Mastercam to run Penta Machine’s 5-axis Pocket NC V2-10 mill at career fairs in its efforts to recruit students into its manufacturing program.

Vantage Career Center

Vantage Career Center leverages partnerships with technology providers and state and local governments to provide world-class precision machining education to its students.