When Craftsmanship Meets Programming

Reimagining Traditional Design Through Precision Machining

Machining the Extraordinary: Industry Leaders Reimagine the Iconic Cuckoo Clock

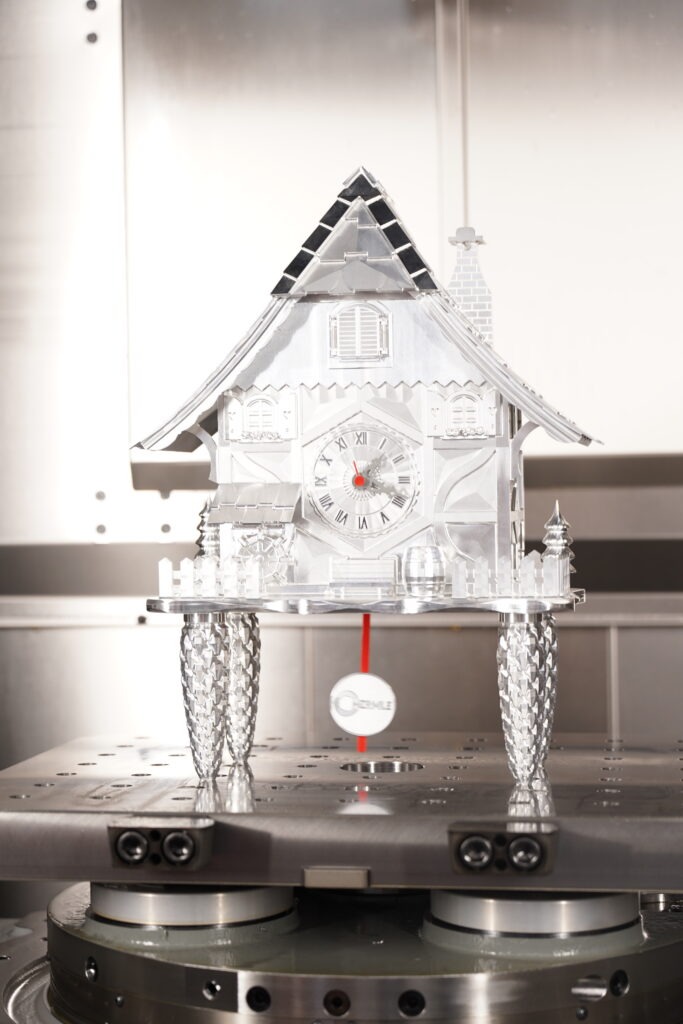

In a whimsical departure from traditional industrial applications, Mastercam, in collaboration with Hermle Machine Tools, SECO Tools, SMW Autoblock, and Vericut Verification, set out to demonstrate what’s possible by creating an extraordinarily intricate, fully machined Cuckoo Clock from a solid 300x300x160 mm block of aluminum. The finished piece will be on display at EMO 2025 conference in Hannover, Germany.

Project Overview

Project Details

The Challenge

Achieving complex designs for made-to-order manufacturing is challenging by definition. Some of the biggest hurdles included achieving highly complex features with advanced 5-axis and mesh-based toolpaths. There was minimal margin for error because the team needed to meet tight deadlines in order to deliver the parts in time for the EMO 2025 tradeshow. Balancing short lead time with high requirements and tight tolerances was a challenge the project team needed to solve.

Delivering on these expectations required design and programming software that is both powerful and intuitive, offering deep control without slowing down the process.

The Solution

Mastercam addressed these challenges head on. Here are the features that proved to be most helpful:

- Advanced Multiaxis toolpaths for complex, organic geometries

- Convert to 5-Axis to adapt 3D paths quickly for full tool orientation control

- Unified toolpaths for precise surface control and collision avoidance

- Mesh-based machining, ideal for imported or scanned data

- Mesh toolpaths allowed full manipulation of mesh bodies, ideal for artistic-type work like the Cuckoo Clock.

- Stock models and simulation for progressive roughing and intelligent planning

These features not only highlighted the incredible potential of precision machining but also served as a platform for experimental design.

The Benefits

- Faster prototyping and iteration for custom, complex geometries

- Cleaner finishes with reliable collision control

- Scalable strategies for both one-off and repeat custom production

- Increased customer satisfaction through precision and design flexibility

"At the beginning, many thought the intricacies of this project were impossible. Seeing it finished proved what this software, cutting tools, and machine combo can do."

The Cuckoo Clock Collaboration

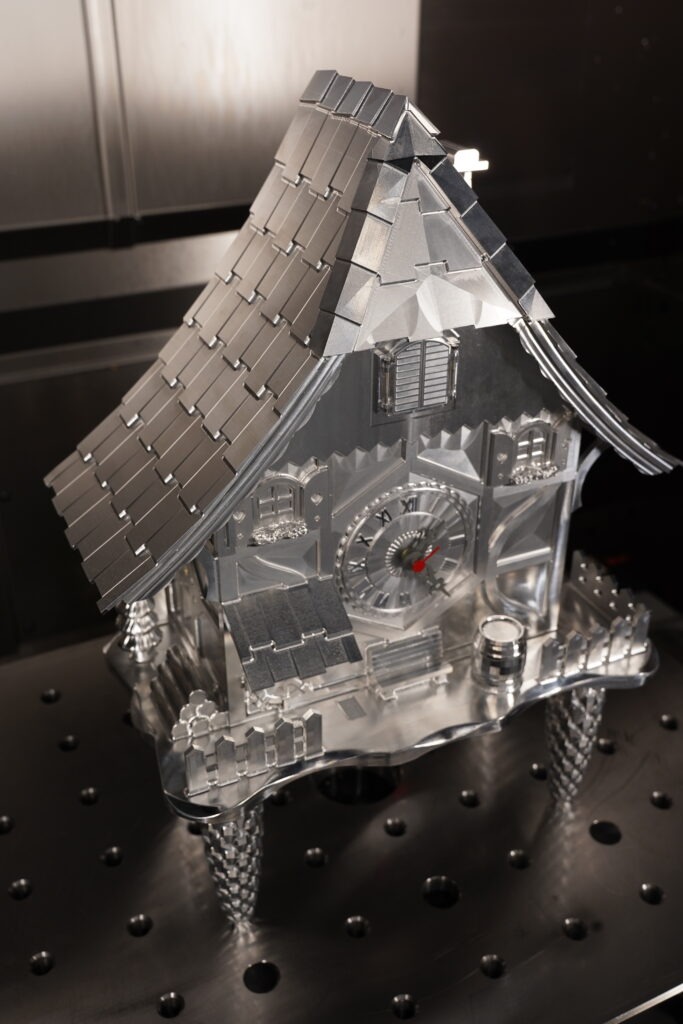

A compelling example of the evolution in precision machining is this modern reinterpretation of the traditional cuckoo clock. Through the integration of advanced programming and machining techniques, our project team set out to merge old-world craftsmanship with modern technological precision.

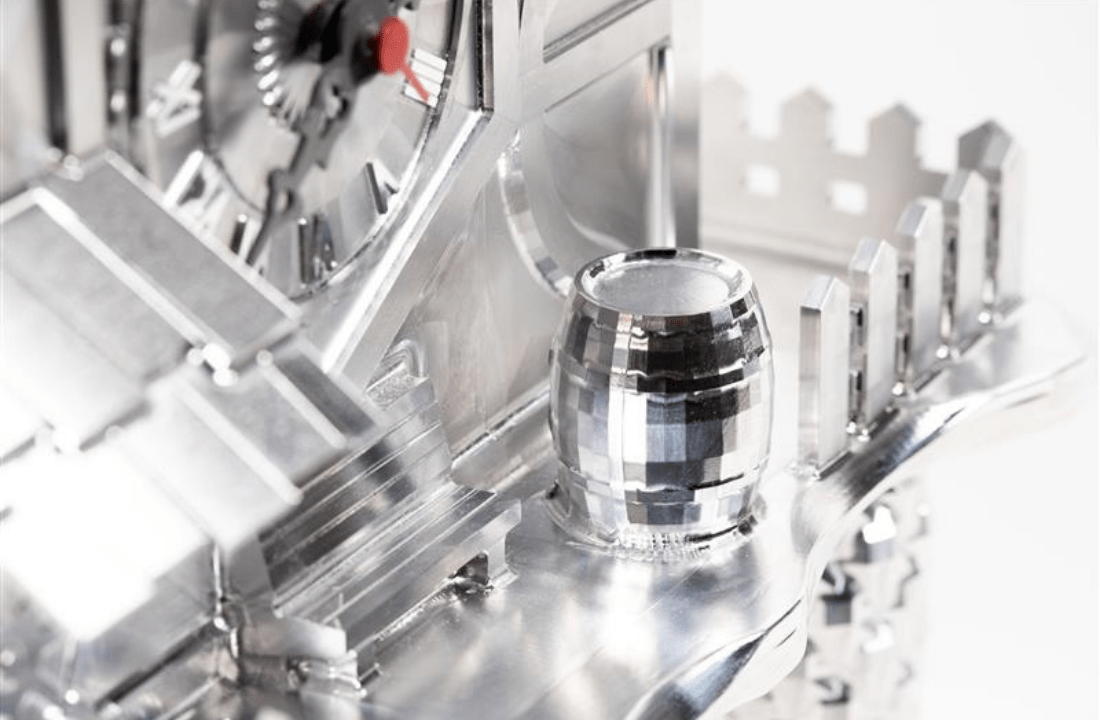

Even carving a wood cuckoo clock is no quick venture and can take up to three weeks to complete. Each clock is a layered masterpiece of intricate designs, painted figures and precision mechanics. Our team’s version was machined from aluminum. Call it functional art.

Working with Multiaxis toolpaths posed significant challenges. Selecting numerous surface facets made it difficult to define precise constraints or guide curves. As a result, the team opted to use 3D toolpaths where possible, which worked effectively on mesh geometry.

“This approach allowed us to define boundaries using wireframes and supplemental meshes, especially helpful in the initial setup to machine the walls and decorative accents beneath the roof,” said Gaetan Schnepp, Mastercam’s Project Lead. “The outcome was a clean, accurate toolpath generated with minimal effort.”

Once the foundational features were complete, the team transitioned the toolpath using the “convert to 5-axis” technique. This enabled the reuse of the existing machining pattern while focusing on three core controls: tool axis orientation, collision management, and refined linking strategies.

“Perhaps the most intricate challenge was machining the stylized trees, which were positioned beneath the roof and partially obstructed by fences,” adds Schnepp. “We preserved their mesh structure to maintain an organic aesthetic, but this introduced additional complexity. To achieve a more defined form, we used refinement techniques that enhanced surface quality.”

Using the concept of a vertically bisected cone, the team was able to isolate and access each side of the tree, machining both front and back with efficiency. The toolpath could be simplified, and collision control mechanisms enabled the tool to retract gracefully along the tree’s surface. This avoided the need for manual manipulation of tool orientation within tight valleys and protruding features.

Key Features That Helped Bring This Project Together

- Mesh Machining: Organic elements like trees beneath the clock’s roof were retained as mesh objects. Using refined 3D toolpaths, the programmer achieved accurate, clean results while preserving shape complexity.

- Convert to 5-Axis: This feature enabled full tool orientation and collision control around difficult areas, such as machining under the roof and behind fences.

- Clean Core Strategy: To access hidden interior features like tree bases, a vertical cone was sectioned and used to guide machining from both front and back.

- Unified Toolpath with Guide Mode: For panels and tight surface areas, guide-based containment strategies allowed optimal passes even if standard parallel paths failed.

- Deburr in 5-Axis: Despite the intricate nature of the part, this toolpath delivered fast, safe edge finishing thanks to accurate machine kinematic awareness and tilt angle restrictions.

- Stock Model Planning: Toolpaths were planned and split into progressive stages, using exported mesh-based stock models to visualize material remaining and segment the job into logical units.

The results spotlight a technical feat. “At the beginning, many thought the intricacies of this project were impossible. Seeing it finished proved what this software, cutting tools, and machine combo can do,” said the technical application expert from Seco.

Precision machining has long been celebrated for its ability to transform raw materials into highly accurate, functional components. The cuckoo clock project is a stunning example of how this technology can be used to create unconventional and intricately designed objects that blend artistry with engineering.

Quick Facts

- Total Machining Time: 47 hours

- Material: Aluminum

- Part Size: 300x300x160 mm

- Machine Platform: Hermle C42series 5-axis

- CAM Platform: Mastercam

- Verification: Vericut

- Tooling: SECO Tools

- Workholding: SMW Autoblock

Video: The Making of the Clock

A closer look at the intricacies of the clock